Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PC<br />

H H<br />

C C<br />

n<br />

H H<br />

CH 3<br />

O<br />

C<br />

O C<br />

CH 3<br />

PE Structural formula PE<br />

O<br />

n<br />

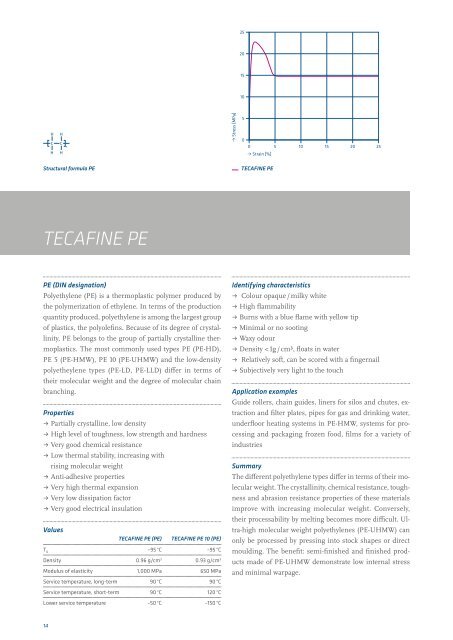

• Stress [MPa]<br />

25<br />

20<br />

PEKEKK<br />

15<br />

10<br />

5<br />

O<br />

0<br />

S<br />

0 5 10 15 20<br />

25<br />

• Strain [%] O<br />

TECAFINE PE<br />

TECAFINE PES<br />

O<br />

O O<br />

O C<br />

O C C<br />

O n<br />

n<br />

TECAFINE PE<br />

O O C<br />

n<br />

O<br />

O<br />

C<br />

O<br />

C<br />

H H<br />

O C C O<br />

H H<br />

n<br />

PEEK<br />

PE (DIN designation)<br />

Polyethylene (PE) is a thermoplastic polymer produced by<br />

the polymerization of ethylene. In terms of the production<br />

quantity produced, polyethylene is among the largest group<br />

of <strong>plastics</strong>, the polyolefins. Because of its degree of crystal-<br />

O<br />

CH 3<br />

linity, CPE belongs to the group of partially crystalline CHther-<br />

mo<strong>plastics</strong>. N <strong>The</strong> most commonly used types PE (PE-HD), N<br />

2<br />

O<br />

C<br />

O<br />

CH 3<br />

C<br />

CH 2<br />

PE 5 (PE-HMW), PE 10 (PE-UHMW) and the low-density<br />

O<br />

polyetheylene types (PE-LD, PE-LLD) differ in terms of<br />

their molecular weight and the degree of molecular chain<br />

PEI<br />

branching.<br />

Properties<br />

ˌˌPartially crystalline, low density<br />

ˌˌHigh level of toughness, low strength and hardness<br />

ˌˌVery good chemical resistance<br />

ˌˌLow thermal stability, increasing with<br />

O<br />

rising molecular weight<br />

O<br />

C<br />

n<br />

ˌˌAnti-adhesive properties<br />

ˌˌVery high thermal expansion<br />

PEK<br />

ˌˌVery low dissipation factor<br />

ˌˌVery good electrical insulation<br />

Values<br />

TECAFINE PE (PE) TECAFINE PE 10 (PE)<br />

T g –95 °C –95 °C<br />

Density 0.96 g/cm 3 0.93 g/cm 3<br />

Modulus of elasticity 1,000 MPa 650 MPa<br />

Service temperature, long-term 90 °C 90 °C<br />

PET<br />

Identifying characteristics<br />

ˌ ˌ Colour opaque / milky white<br />

ˌˌHigh flammability<br />

ˌˌBurns with a blue flame with yellow tip<br />

ˌˌMinimal or no O sooting O<br />

O<br />

ˌˌWaxy odour C<br />

C<br />

C<br />

ˌˌDensity -R < N1g / cm³, floats in water N -R<br />

n<br />

n<br />

ˌ ˌ Relatively soft, C can be scored with a C fingernail<br />

O<br />

O<br />

ˌˌSubjectively very light to the touch<br />

PI<br />

Application examples<br />

Guide rollers, chain guides, liners for silos and chutes, extraction<br />

and filter plates, pipes for gas and drinking water,<br />

underfloor heating systems in PE-HMW, systems for processing<br />

and packaging frozen food, films for a variety of<br />

H H<br />

industries<br />

C<br />

C<br />

n<br />

CH 2 H<br />

Summary<br />

CH<br />

H 3 C CH<br />

<strong>The</strong> different polyethylene 3<br />

types differ in terms of their molecular<br />

weight. <strong>The</strong> crystallinity, chemical resistance, toughness<br />

and abrasion resistance properties of these materials<br />

PMP<br />

improve with increasing molecular weight. Conversely,<br />

their processability by melting becomes more difficult. Ultra-high<br />

molecular weight polyethylenes (PE-UHMW) can<br />

only be processed by pressing into stock shapes or direct<br />

moulding. <strong>The</strong> benefit: semi-finished and finished products<br />

made of PE-UHMW demonstrate low internal stress<br />

and minimal warpage.<br />

N<br />

O<br />

C<br />

C<br />

O<br />

O<br />

C<br />

C<br />

O<br />

N<br />

m<br />

Service temperature, short-term 90 °C 120 °C<br />

Lower service temperature –50 °C –150 °C<br />

14