Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Modifications / additives<br />

<strong>The</strong>rmo<strong>plastics</strong> can be modified over an extremely wide<br />

spectrum by the selective integration of additives and fillers.<br />

This allows the characteristics of a material to be<br />

adapted for a specific area of application. <strong>The</strong> most common<br />

modifications in the field of engineering and hightemperature<br />

<strong>plastics</strong> are:<br />

Reinforcing fibres<br />

Glass fibres<br />

Glass fibres are primarily used to increase strength values.<br />

ˌˌIncreased tensile strength,<br />

compressive strength and rigidity<br />

ˌˌImproved creep strength<br />

ˌˌIncreased thermal dimensional stability<br />

ˌˌReduction of thermal expansion and shrinkage<br />

ˌˌReduction of toughness and consequently<br />

breaking strength and impact strength<br />

Please note:<br />

Glass fibres have an abrasive effect. For this reason, glass<br />

fibre-reinforced materials are<br />

ˌˌless suited for sliding friction applications (high<br />

abrasion of the sliding partner) and when processed<br />

bring about increased levels of tool wear (shortened<br />

service life)<br />

Carbon fibres<br />

Carbon fibres have a similar effect to glass fibres, but<br />

ˌˌcarbon fibres provide a better weight-to-strength ratio<br />

(lower density with comparable increase in strength)<br />

ˌˌcarbon fibres are not as abrasive as glass fibres, and are<br />

consequently suitable for sliding friction applications<br />

ˌˌthe influence of carbon fibres on electrical properties<br />

can be disregarded (including undefined electrical<br />

conductivity)<br />

ˌˌcarbon fibres are more expensive the glass fibres<br />

Additional reinforcing fibres<br />

ˌˌAramid fibres<br />

ˌˌMineral fibres<br />

can be offered as non-standard options<br />

Friction-reducing additives<br />

PTFE<br />

Under compressive stress, abraded material from PTFEfilled<br />

<strong>plastics</strong> forms a fine polymer film with sliding properties<br />

on the sliding surface.<br />

ˌˌTypically pronounced anti-adhesive behaviour<br />

ˌˌEffective avoidance of stick-slip effect<br />

UHMW-PE<br />

Demonstrates similar effects to PTFE in a less pronounced<br />

form.<br />

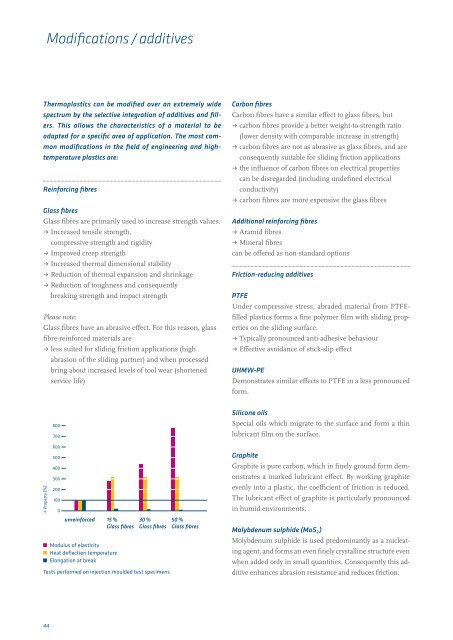

• Property [%]<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

unreinforced 15 %<br />

Glass fibres<br />

Modulus of elasticity<br />

Heat deflection temperature<br />

Elongation at break<br />

30 %<br />

Glass fibres<br />

Tests performed on injection moulded test specimens<br />

50 %<br />

Glass fibres<br />

Silicone oils<br />

Special oils which migrate to the surface and form a thin<br />

lubricant film on the surface.<br />

Graphite<br />

Graphite is pure carbon, which in finely ground form demonstrates<br />

a marked lubricant effect. By working graphite<br />

evenly into a plastic, the coefficient of friction is reduced.<br />

<strong>The</strong> lubricant effect of graphite is particularly pronounced<br />

in humid environments.<br />

Molybdenum sulphide (MoS 2 )<br />

Molybdenum sulphide is used predominantly as a nucleating<br />

agent, and forms an even finely crystalline structure even<br />

when added only in small quantities. Consequently this additive<br />

enhances abrasion resistance and reduces friction.<br />

44