Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Tribological characteristics<br />

Generally speaking, <strong>plastics</strong> are very good sliding materials<br />

with a low coefficient of friction. Conversely, their abrasion<br />

resistance is also high under dry running conditions. In a<br />

similar way to the mechanical characteristics, tribological<br />

characteristics depend heavily on ambient conditions, in<br />

other words on the sliding system. Load, sliding speed and<br />

type of movement (oscillating, rotating etc.) exert a considerable<br />

influence here. In addition, the material characteristics<br />

of the sliding partner and its surface properties also<br />

exert an influence on the sliding properties of the system.<br />

For example the rough surfaces of harder sliding partners<br />

(steel) are more likely to cause wear in softer sliding partners.<br />

Also where a combination of high sliding speeds and<br />

high pressing forces are at work, the sliding partners are<br />

exposed to high levels of stress.<br />

Given these circumstances, tribological variables (such as<br />

the coefficient of friction and abrasion) must always be considered<br />

in the light of the test system used. Typical measurement<br />

methods such as ball prism and pin-on-disc testing<br />

are described in ISO 7148. However, when performing<br />

service life calculations and similar, application-specific<br />

tests should be carried out.<br />

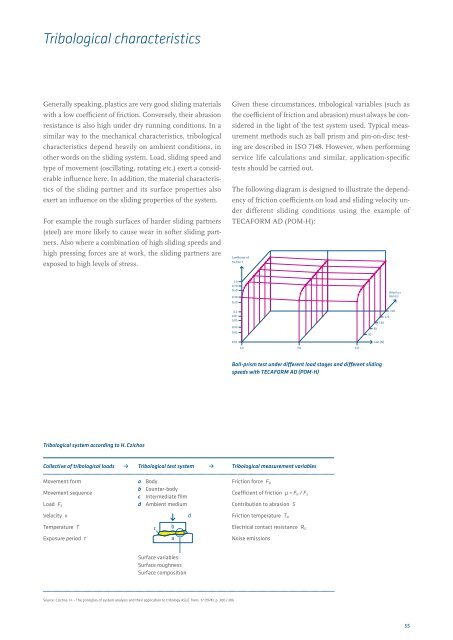

<strong>The</strong> following diagram is designed to illustrate the dependency<br />

of friction coefficients on load and sliding velocity under<br />

different sliding conditions using the example of<br />

TECAFORM AD (POM-H):<br />

Coefficient of<br />

friction f<br />

1,0<br />

0,70<br />

0,50<br />

0,30<br />

0,20<br />

Velocity v<br />

[mm/s]<br />

0,1<br />

0,07<br />

0,05<br />

0,03<br />

0,02<br />

0,01<br />

210<br />

170<br />

130<br />

90<br />

50<br />

Last [N]<br />

1,0<br />

3,0<br />

6,0<br />

Ball-prism test under different load stages and different sliding<br />

speeds with TECAFORM AD (POM-H)<br />

Tribological system according to H. Czichos<br />

Collective of tribological loads<br />

Movement form<br />

Movement sequence<br />

Load F S<br />

Velocity v<br />

Temperature T<br />

Exposure period t<br />

• Tribological test system<br />

a Body<br />

b Counter-body<br />

c Intermediate film<br />

d Ambient medium<br />

d<br />

c b<br />

a<br />

• Tribological measurement variables<br />

Friction force F R<br />

Coefficient of friction µ = F R / F S<br />

Contribution to abrasion S<br />

Friction temperature T R<br />

Electrical contact resistance R Ü<br />

Noise emissions<br />

Surface variables:<br />

Surface roughness<br />

Surface composition<br />

Source: Czichos, H. – <strong>The</strong> principles of system analysis and their application to tribology ASLE Trans. 17 (1974), p. 300 / 306<br />

55