Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

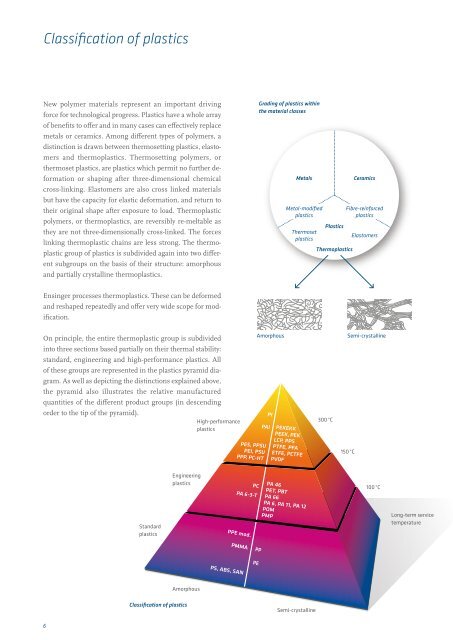

Classification of <strong>plastics</strong><br />

New polymer materials represent an important driving<br />

force for technological progress. Plastics have a whole array<br />

of benefits to offer and in many cases can effectively replace<br />

metals or ceramics. Among different types of polymers, a<br />

distinction is drawn between thermosetting <strong>plastics</strong>, elastomers<br />

and thermo<strong>plastics</strong>. <strong>The</strong>rmosetting polymers, or<br />

thermoset <strong>plastics</strong>, are <strong>plastics</strong> which permit no further deformation<br />

or shaping after three-dimensional chemical<br />

cross-linking. Elastomers are also cross linked materials<br />

but have the capacity for elastic deformation, and return to<br />

their original shape after exposure to load. <strong>The</strong>rmoplastic<br />

polymers, or thermo<strong>plastics</strong>, are reversibly re-meltable as<br />

they are not three-dimensionally cross-linked. <strong>The</strong> forces<br />

linking thermoplastic chains are less strong. <strong>The</strong> thermoplastic<br />

group of <strong>plastics</strong> is subdivided again into two different<br />

subgroups on the basis of their structure: amorphous<br />

and partially crystalline thermo<strong>plastics</strong>.<br />

Grading of <strong>plastics</strong> within<br />

the material classes<br />

Metals<br />

Metal-modified<br />

<strong>plastics</strong><br />

Ceramics<br />

Fibre-reinforced<br />

<strong>plastics</strong><br />

Plastics<br />

<strong>The</strong>rmoset<br />

Elastomers<br />

<strong>plastics</strong><br />

<strong>The</strong>rmo<strong>plastics</strong><br />

Ensinger processes thermo<strong>plastics</strong>. <strong>The</strong>se can be deformed<br />

and reshaped repeatedly and offer very wide scope for modification.<br />

On principle, the entire thermoplastic group is subdivided<br />

into three sections based partially on their thermal stability:<br />

standard, engineering and high-performance <strong>plastics</strong>. All<br />

of these groups are represented in the <strong>plastics</strong> pyramid diagram.<br />

As well as depicting the distinctions explained above,<br />

the pyramid also illustrates the relative manufactured<br />

quantities of the different product groups (in descending<br />

order to the tip of the pyramid).<br />

High-performance<br />

<strong>plastics</strong><br />

PI<br />

PAI<br />

PES, PPSU<br />

PEI, PSU<br />

PPP, PC-HT<br />

Amorphous<br />

PEKEKK<br />

PEEK, PEK<br />

LCP, PPS<br />

PTFE, PFA<br />

ETFE, PCTFE<br />

PVDF<br />

300 °C<br />

Semi-crystalline<br />

150 °C<br />

Standard<br />

<strong>plastics</strong><br />

<strong>Engineering</strong><br />

<strong>plastics</strong><br />

PC<br />

PA 6-3-T<br />

PPE mod.<br />

PA 46<br />

PET, PBT<br />

PA 66<br />

PA 6, PA 11, PA 12<br />

POM<br />

PMP<br />

100 °C<br />

Long-term service<br />

temperature<br />

PMMA<br />

PP<br />

PE<br />

PS, ABS, SAN<br />

Amorphous<br />

Classification of <strong>plastics</strong><br />

Semi-crystalline<br />

6