Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

0<br />

0<br />

0<br />

0<br />

0<br />

5<br />

0<br />

0<br />

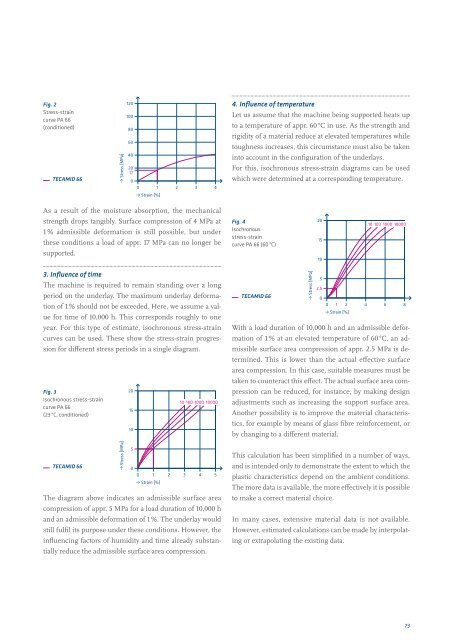

Fig. 2<br />

Stress-strain<br />

curve PA 66<br />

(conditioned)<br />

TECAMID 66<br />

0 1 2 3 4<br />

• Stress [MPa]<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

17<br />

0<br />

0 1 2 3 4<br />

• Strain [%]<br />

4. Influence 20 of temperature<br />

Let us assume that the machine 10 100 1000 being 10000 supported heats up<br />

15<br />

15<br />

to a temperature of appr. 60 °C in use. As the strength and<br />

rigidity of a material reduce at elevated temperatures while<br />

10<br />

10<br />

toughness increases, this circumstance must also be taken<br />

into account in the configuration of the underlays.<br />

5<br />

5<br />

For this, isochronous stress-strain diagrams can be used<br />

2.5<br />

which were determined at a corresponding temperature.<br />

0<br />

0 1 2 3 4 5<br />

20<br />

0<br />

0 1 2 4<br />

10 100 1<br />

As a result of the moisture absorption, the mechanical<br />

strength 20 drops tangibly. Surface compression of 204 MPa at<br />

1 % admissible deformation 10 100 1000 is 10000 still possible, but under<br />

15<br />

15<br />

these conditions a load of appr. 17 MPa can no longer be<br />

supported.<br />

10<br />

10<br />

Fig. 10 4 100 1000 10000<br />

Isochronous<br />

stress-strain<br />

curve PA 66 (60 °C)<br />

20<br />

15<br />

10<br />

10 100 1000 10000<br />

0<br />

0<br />

0<br />

0<br />

0<br />

0<br />

7<br />

0<br />

4<br />

3. Influence of time<br />

5<br />

5<br />

<strong>The</strong> machine is required to remain standing over a long<br />

2.5<br />

period on the underlay. <strong>The</strong> maximum underlay deforma-<br />

0<br />

0<br />

TECAMID 66<br />

0 1 2 3 4 5<br />

0 1 2 4 6 8<br />

tion of 1 % should not be exceeded. Here, we assume a value<br />

for time of 10,000 h. This corresponds roughly to one<br />

year. For this type of estimate, isochronous stress-strain<br />

curves can be used. <strong>The</strong>se show the stress-strain progression<br />

for different stress periods in a single diagram.<br />

Fig. 3<br />

Isochronous stress-strain<br />

curve PA 66<br />

(23 °C, conditioned)<br />

TECAMID 66<br />

0 1 2 3 4<br />

• Stress [MPa]<br />

20<br />

15<br />

10<br />

5<br />

0<br />

10 100 1000 10000<br />

0 1 2 3 4 5<br />

• Strain [%]<br />

<strong>The</strong> diagram above indicates an admissible surface area<br />

compression of appr. 5 MPa for a load duration of 10,000 h<br />

and an admissible deformation of 1 %. <strong>The</strong> underlay would<br />

still fulfil its purpose under these conditions. However, the<br />

influencing factors of humidity and time already substantially<br />

reduce the admissible surface area compression.<br />

With a load duration of 10,000 h and an admissible deformation<br />

of 1 % at an elevated temperature of 60 °C, an admissible<br />

surface area compression of appr. 2.5 MPa is determined.<br />

This is lower than the actual effective surface<br />

area compression. In this case, suitable measures must be<br />

taken to counteract this effect. <strong>The</strong> actual surface area compression<br />

20can be reduced, 20<br />

10<br />

for<br />

100 1000<br />

instance,<br />

10000<br />

by making design<br />

5<br />

• Stress [MPa]<br />

5<br />

2.5<br />

0<br />

0 1 2 4 6 8<br />

• Strain [%]<br />

adjustments such as increasing the support surface area.<br />

15<br />

15<br />

Another possibility is to improve the material characteristics,<br />

for example by means of glass fibre reinforcement, or<br />

10<br />

10<br />

by changing to a different material.<br />

This calculation has been simplified in a number of ways,<br />

2.5<br />

2.5<br />

and is intended only to demonstrate the extent to which the<br />

0<br />

0<br />

0 1 2 4 6 8<br />

0 1 2 4 6<br />

plastic characteristics depend on the ambient conditions.<br />

<strong>The</strong> more data is available, the more effectively it is possible<br />

to make a correct material choice.<br />

In many cases, extensive material data is not available.<br />

However, estimated calculations can be made by interpolating<br />

or extrapolating the existing data.<br />

5<br />

10 100 10<br />

73