Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

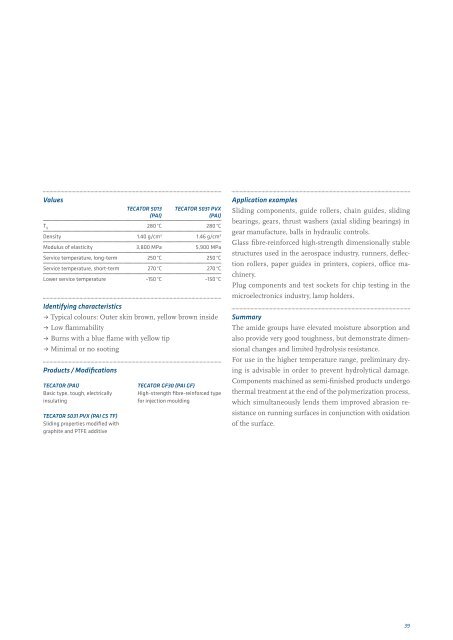

Values<br />

TECATOR 5013<br />

(PAI)<br />

TECATOR 5031 PVX<br />

(PAI)<br />

T g 280 °C 280 °C<br />

Density 1.40 g/cm 3 1.46 g/cm 3<br />

Modulus of elasticity 3,800 MPa 5,900 MPa<br />

Service temperature, long-term 250 °C 250 °C<br />

Service temperature, short-term 270 °C 270 °C<br />

Lower service temperature –150 °C –150 °C<br />

Identifying characteristics<br />

ˌˌTypical colours: Outer skin brown, yellow brown inside<br />

ˌˌLow flammability<br />

ˌˌBurns with a blue flame with yellow tip<br />

ˌˌMinimal or no sooting<br />

Products / Modifications<br />

TECATOR (PAI)<br />

Basic type, tough, electrically<br />

insulating<br />

TECATOR 5031 PVX (PAI CS TF)<br />

Sliding properties modified with<br />

graphite and PTFE additive<br />

TECATOR GF30 (PAI GF)<br />

High-strength fibre-reinforced type<br />

for injection moulding<br />

Application examples<br />

Sliding components, guide rollers, chain guides, sliding<br />

bearings, gears, thrust washers (axial sliding bearings) in<br />

gear manufacture, balls in hydraulic controls.<br />

Glass fibre-reinforced high-strength dimensionally stable<br />

structures used in the aerospace industry, runners, deflection<br />

rollers, paper guides in printers, copiers, office machinery.<br />

Plug components and test sockets for chip testing in the<br />

microelectronics industry, lamp holders.<br />

Summary<br />

<strong>The</strong> amide groups have elevated moisture absorption and<br />

also provide very good toughness, but demonstrate dimensional<br />

changes and limited hydrolysis resistance.<br />

For use in the higher temperature range, preliminary drying<br />

is advisable in order to prevent hydrolytical damage.<br />

Components machined as semi-finished products undergo<br />

thermal treatment at the end of the polymerization process,<br />

which simultaneously lends them improved abrasion resistance<br />

on running surfaces in conjunction with oxidation<br />

of the surface.<br />

39