Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Other thermal specifications<br />

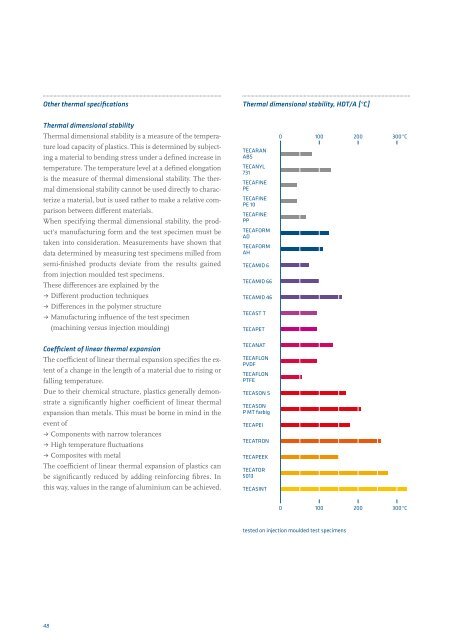

<strong>The</strong>rmal dimensional stability, HDT/A [°C]<br />

<strong>The</strong>rmal dimensional stability<br />

<strong>The</strong>rmal dimensional stability is a measure of the temperature<br />

load capacity of <strong>plastics</strong>. This is determined by subjecting<br />

a material to bending stress under a defined increase in<br />

temperature. <strong>The</strong> temperature level at a defined elongation<br />

is the measure of thermal dimensional stability. <strong>The</strong> thermal<br />

dimensional stability cannot be used directly to characterize<br />

a material, but is used rather to make a relative comparison<br />

between different materials.<br />

When specifying thermal dimensional stability, the product's<br />

manufacturing form and the test specimen must be<br />

taken into consideration. Measurements have shown that<br />

data determined by measuring test specimens milled from<br />

semi-finished products deviate from the results gained<br />

from injection moulded test specimens.<br />

<strong>The</strong>se differences are explained by the<br />

ˌˌDifferent production techniques<br />

ˌˌDifferences in the polymer structure<br />

ˌˌManufacturing influence of the test specimen<br />

(machining versus injection moulding)<br />

TECARAN<br />

ABS<br />

TECANYL<br />

731<br />

TECAFINE<br />

PE<br />

TECAFINE<br />

PE 10<br />

TECAFINE<br />

PP<br />

TECAFORM<br />

AD<br />

TECAFORM<br />

AH<br />

TECAMID 6<br />

TECAMID 66<br />

TECAMID 46<br />

TECAST T<br />

TECAPET<br />

0<br />

100<br />

200<br />

300 °C<br />

Coefficient of linear thermal expansion<br />

<strong>The</strong> coefficient of linear thermal expansion specifies the extent<br />

of a change in the length of a material due to rising or<br />

falling temperature.<br />

Due to their chemical structure, <strong>plastics</strong> generally demonstrate<br />

a significantly higher coefficient of linear thermal<br />

expansion than metals. This must be borne in mind in the<br />

event of<br />

ˌˌComponents with narrow tolerances<br />

ˌˌHigh temperature fluctuations<br />

ˌˌComposites with metal<br />

<strong>The</strong> coefficient of linear thermal expansion of <strong>plastics</strong> can<br />

be significantly reduced by adding reinforcing fibres. In<br />

this way, values in the range of aluminium can be achieved.<br />

TECANAT<br />

TECAFLON<br />

PVDF<br />

TECAFLON<br />

PTFE<br />

TECASON S<br />

TECASON<br />

P MT farbig<br />

TECAPEI<br />

TECATRON<br />

TECAPEEK<br />

TECATOR<br />

5013<br />

TECASINT<br />

0<br />

100<br />

200<br />

300 °C<br />

tested on injection moulded test specimens<br />

48