Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Bonding<br />

Bonding technology is a very efficient joining method<br />

which permits <strong>plastics</strong> to be permanently joined to themselves<br />

or other materials. <strong>The</strong> chemical joining (bonding)<br />

of components offers a range of benefits compared to other<br />

joining methods:<br />

ˌˌEven distribution of stress<br />

ˌˌNo damage to materials<br />

ˌˌNo warping of joined parts<br />

ˌˌDifferent material combinations can be joined<br />

ˌˌ<strong>The</strong> separating joint is sealed at the same time<br />

ˌˌA smaller number of components is required<br />

Decisive factors for a good bonded joint:<br />

ˌˌMaterial characteristics<br />

ˌˌAdhesive<br />

ˌˌAdhesive layer<br />

ˌˌSurface (preliminary treatment)<br />

ˌˌGeometric design of the bonded joint<br />

ˌˌApplication and load conditions<br />

To increase the strength of a bonded joint, it is advisable to<br />

pre-treat the surfaces when bonding <strong>plastics</strong> in order to enhance<br />

surface activity.<br />

ˌˌCleaning and degreasing the material surface<br />

ˌˌIncreasing the size of the mechanical surface by<br />

grinding or sand blasting (particularly recommended)<br />

ˌˌPhysical activation of the surface by flame, plasma or<br />

corona treatment<br />

ˌˌChemical etching for the formation of a defined<br />

boundary layer<br />

ˌˌPrimer application<br />

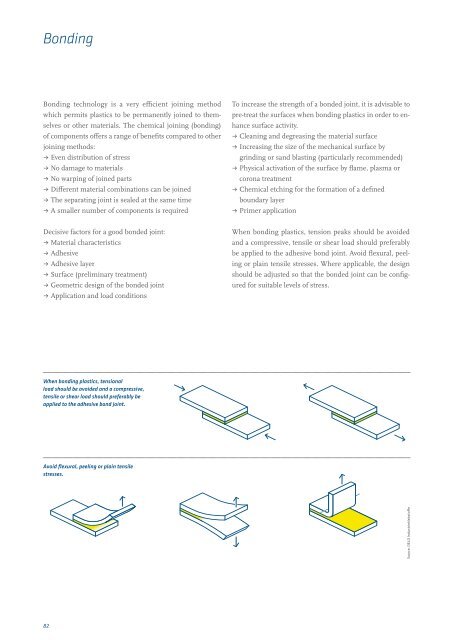

When bonding <strong>plastics</strong>, tension peaks should be avoided<br />

and a compressive, tensile or shear load should preferably<br />

be applied to the adhesive bond joint. Avoid flexural, peeling<br />

or plain tensile stresses. Where applicable, the design<br />

should be adjusted so that the bonded joint can be configured<br />

for suitable levels of stress.<br />

When bonding <strong>plastics</strong>, tensional<br />

load should be avoided and a compressive,<br />

tensile or shear load should preferably be<br />

applied to the adhesive bond joint.<br />

Avoid flexural, peeling or plain tensile<br />

stresses.<br />

Source: DELO Industrieklebstoffe<br />

82