Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Cleaning <strong>plastics</strong><br />

According to DIN 8592, cleaning is a chemical process<br />

used in manufacturing to remove residues.<br />

<strong>The</strong> following cleaning methods are particularly suitable<br />

for plastic cleaning:<br />

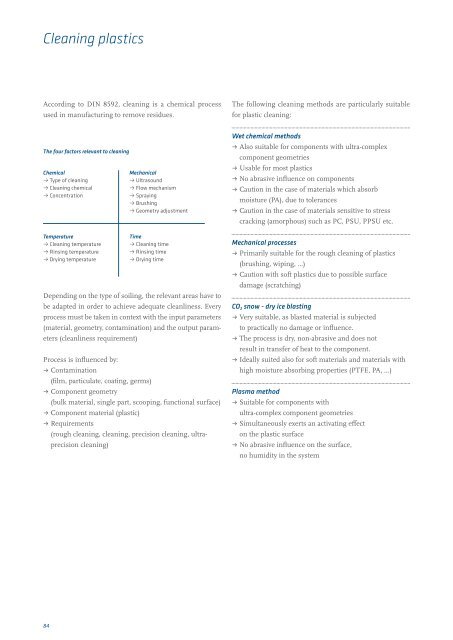

<strong>The</strong> four factors relevant to cleaning<br />

Chemical<br />

• Type of cleaning<br />

• Cleaning chemical<br />

• Concentration<br />

Temperature<br />

• Cleaning temperature<br />

• Rinsing temperature<br />

• Drying temperature<br />

Mechanical<br />

• Ultrasound<br />

• Flow mechanism<br />

• Spraying<br />

• Brushing<br />

• Geometry adjustment<br />

Time<br />

• Cleaning time<br />

• Rinsing time<br />

• Drying time<br />

Depending on the type of soiling, the relevant areas have to<br />

be adapted in order to achieve adequate cleanliness. Every<br />

process must be taken in context with the input parameters<br />

(material, geometry, contamination) and the output parameters<br />

(cleanliness requirement)<br />

Process is influenced by:<br />

ˌˌContamination<br />

(film, particulate, coating, germs)<br />

ˌˌComponent geometry<br />

(bulk material, single part, scooping, functional surface)<br />

ˌˌComponent material (plastic)<br />

ˌˌRequirements<br />

(rough cleaning, cleaning, precision cleaning, ultraprecision<br />

cleaning)<br />

Wet chemical methods<br />

ˌˌAlso suitable for components with ultra-complex<br />

component geometries<br />

ˌˌUsable for most <strong>plastics</strong><br />

ˌˌNo abrasive influence on components<br />

ˌˌCaution in the case of materials which absorb<br />

moisture (PA), due to tolerances<br />

ˌˌCaution in the case of materials sensitive to stress<br />

cracking (amorphous) such as PC, PSU, PPSU etc.<br />

Mechanical processes<br />

ˌˌPrimarily suitable for the rough cleaning of <strong>plastics</strong><br />

(brushing, wiping, …)<br />

ˌˌCaution with soft <strong>plastics</strong> due to possible surface<br />

damage (scratching)<br />

CO 2 snow - dry ice blasting<br />

ˌˌVery suitable, as blasted material is subjected<br />

to practically no damage or influence.<br />

ˌˌ<strong>The</strong> process is dry, non-abrasive and does not<br />

result in transfer of heat to the component.<br />

ˌˌIdeally suited also for soft materials and materials with<br />

high moisture absorbing properties (PTFE, PA, …)<br />

Plasma method<br />

ˌˌSuitable for components with<br />

ultra-complex component geometries<br />

ˌˌSimultaneously exerts an activating effect<br />

on the plastic surface<br />

ˌˌNo abrasive influence on the surface,<br />

no humidity in the system<br />

84