Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

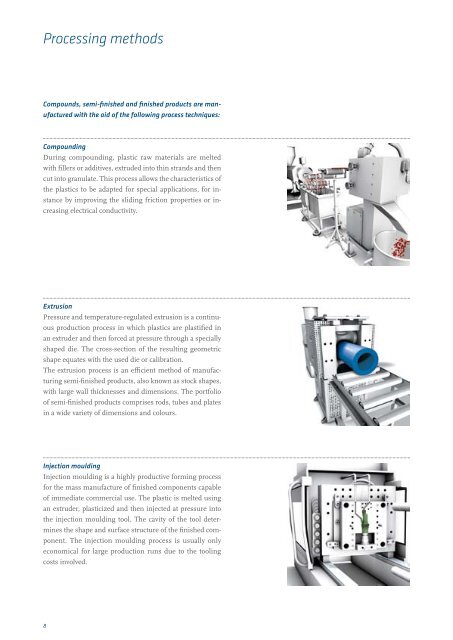

Processing methods<br />

Compounds, semi-finished and finished products are manufactured<br />

with the aid of the following process techniques:<br />

Compounding<br />

During compounding, plastic raw materials are melted<br />

with fillers or additives, extruded into thin strands and then<br />

cut into granulate. This process allows the characteristics of<br />

the <strong>plastics</strong> to be adapted for special applications, for instance<br />

by improving the sliding friction properties or increasing<br />

electrical conductivity.<br />

Extrusion<br />

Pressure and temperature-regulated extrusion is a continuous<br />

production process in which <strong>plastics</strong> are plastified in<br />

an extruder and then forced at pressure through a specially<br />

shaped die. <strong>The</strong> cross-section of the resulting geometric<br />

shape equates with the used die or calibration.<br />

<strong>The</strong> extrusion process is an efficient method of manufacturing<br />

semi-finished products, also known as stock shapes,<br />

with large wall thicknesses and dimensions. <strong>The</strong> portfolio<br />

of semi-finished products comprises rods, tubes and plates<br />

in a wide variety of dimensions and colours.<br />

Injection moulding<br />

Injection moulding is a highly productive forming process<br />

for the mass manufacture of finished components capable<br />

of immediate commercial use. <strong>The</strong> plastic is melted using<br />

an extruder, plasticized and then injected at pressure into<br />

the injection moulding tool. <strong>The</strong> cavity of the tool determines<br />

the shape and surface structure of the finished component.<br />

<strong>The</strong> injection moulding process is usually only<br />

economical for large production runs due to the tooling<br />

costs involved.<br />

8