Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Material chosen<br />

Criteria for material selection<br />

When looking for a suitable plastic, the application conditions<br />

involved determine the material selection. For this<br />

reason, different specific framework conditions must be<br />

known and assessed, for example the planned purpose, the<br />

fields of application and further-reaching details relating to<br />

the characteristics and application conditions. With the aid<br />

of this information, qualified experts can compare the requirements<br />

to technical values and make an assessment.<br />

On the basis of defined criteria, in this way it is possible to<br />

continuously limit the choice of suitable materials.<br />

However, the selection can only be a recommendation,<br />

which cannot replace practical testing.<br />

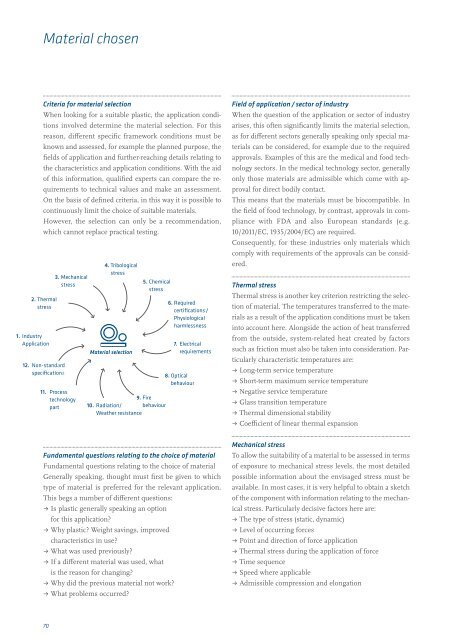

2. <strong>The</strong>rmal<br />

stress<br />

1. Industry<br />

Application<br />

12. Non-standard<br />

specifications<br />

3. Mechanical<br />

stress<br />

11. Process<br />

technology<br />

part<br />

4. Tribological<br />

stress<br />

Material selection<br />

5. Chemical<br />

stress<br />

9. Fire<br />

10. Radiation/ behaviour<br />

Weather resistance<br />

6. Required<br />

certifications /<br />

Physiological<br />

harmlessness<br />

7. Electrical<br />

requirements<br />

8. Optical<br />

behaviour<br />

Field of application / sector of industry<br />

When the question of the application or sector of industry<br />

arises, this often significantly limits the material selection,<br />

as for different sectors generally speaking only special materials<br />

can be considered, for example due to the required<br />

approvals. Examples of this are the medical and food technology<br />

sectors. In the medical technology sector, generally<br />

only those materials are admissible which come with approval<br />

for direct bodily contact.<br />

This means that the materials must be biocompatible. In<br />

the field of food technology, by contrast, approvals in compliance<br />

with FDA and also European standards (e.g.<br />

10/2011/EC, 1935/2004/EC) are required.<br />

Consequently, for these industries only materials which<br />

comply with requirements of the approvals can be considered.<br />

<strong>The</strong>rmal stress<br />

<strong>The</strong>rmal stress is another key criterion restricting the selection<br />

of material. <strong>The</strong> temperatures transferred to the materials<br />

as a result of the application conditions must be taken<br />

into account here. Alongside the action of heat transferred<br />

from the outside, system-related heat created by factors<br />

such as friction must also be taken into consideration. Particularly<br />

characteristic temperatures are:<br />

ˌˌLong-term service temperature<br />

ˌˌShort-term maximum service temperature<br />

ˌˌNegative service temperature<br />

ˌˌGlass transition temperature<br />

ˌˌ<strong>The</strong>rmal dimensional stability<br />

ˌˌCoefficient of linear thermal expansion<br />

Fundamental questions relating to the choice of material<br />

Fundamental questions relating to the choice of material<br />

Generally speaking, thought must first be given to which<br />

type of material is preferred for the relevant application.<br />

This begs a number of different questions:<br />

ˌˌIs plastic generally speaking an option<br />

for this application?<br />

ˌˌWhy plastic? Weight savings, improved<br />

characteristics in use?<br />

ˌˌWhat was used previously?<br />

ˌˌIf a different material was used, what<br />

is the reason for changing?<br />

ˌˌWhy did the previous material not work?<br />

ˌˌWhat problems occurred?<br />

Mechanical stress<br />

To allow the suitability of a material to be assessed in terms<br />

of exposure to mechanical stress levels, the most detailed<br />

possible information about the envisaged stress must be<br />

available. In most cases, it is very helpful to obtain a sketch<br />

of the component with information relating to the mechanical<br />

stress. Particularly decisive factors here are:<br />

ˌˌ<strong>The</strong> type of stress (static, dynamic)<br />

ˌˌLevel of occurring forces<br />

ˌˌPoint and direction of force application<br />

ˌˌ<strong>The</strong>rmal stress during the application of force<br />

ˌˌTime sequence<br />

ˌˌSpeed where applicable<br />

ˌˌAdmissible compression and elongation<br />

70