Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PEI<br />

PI<br />

O O C<br />

O<br />

n<br />

160<br />

O<br />

C<br />

O<br />

C<br />

H H<br />

O C C O<br />

H H<br />

n<br />

Structural PEEK formula PEEK<br />

120<br />

PET<br />

H<br />

H<br />

O<br />

O<br />

C<br />

n<br />

80<br />

C H 3<br />

C C<br />

n<br />

CH 2 H<br />

CH<br />

CH 3<br />

PEK<br />

Structural O formula PEK<br />

CH 3<br />

C<br />

O<br />

C<br />

O<br />

N<br />

O<br />

O CH O 3<br />

C<br />

O C<br />

O C C<br />

n<br />

O<br />

PEKEKK PEI Structural formula PEKEKK<br />

TECAPEEK<br />

O<br />

O<br />

S<br />

O n<br />

O<br />

C<br />

O<br />

n<br />

CH 2<br />

CH 2<br />

N<br />

• Stress [MPa]<br />

40<br />

PMP<br />

TECAPEEK TECAPEEK<br />

POM-C PI ST black TECAPEEK TECAPEEK HT black<br />

H H<br />

C C<br />

n<br />

H<br />

CH 2 H<br />

C O<br />

n<br />

CH<br />

H 3 CH<br />

CH 3<br />

O<br />

O<br />

O<br />

O<br />

C<br />

C<br />

C<br />

C<br />

-R H<br />

N H H<br />

N -R N<br />

n<br />

n<br />

0<br />

C OC<br />

C C O<br />

0 5 l<br />

10m<br />

n<br />

15<br />

C<br />

20<br />

C<br />

• Strain [%] H O H H<br />

O<br />

O<br />

TECAPEEK ST sw<br />

TECAPEEK HT sw<br />

O<br />

C<br />

C<br />

O<br />

N<br />

m<br />

n<br />

PES PEK<br />

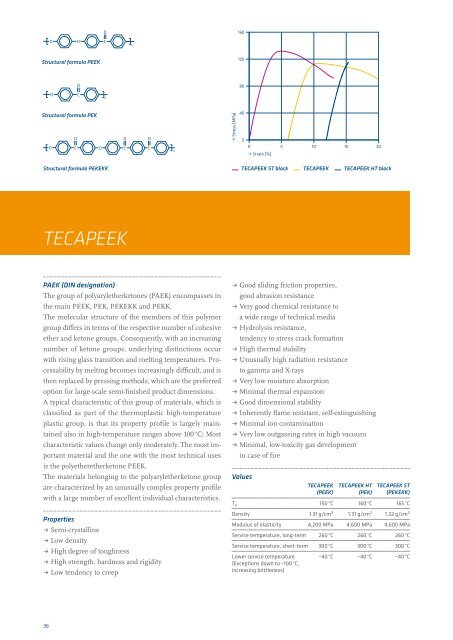

PAEK (DIN designation)<br />

<strong>The</strong> group of polyaryletherketones (PAEK) encompasses in<br />

the main PEEK, PEK, PEKEKK and PEKK.<br />

<strong>The</strong> molecular structure of the members of this polymer<br />

group differs in terms of the respective number of cohesive<br />

ether and ketone groups. Consequently, with an increasing<br />

number O of Oketone H groups, H underlying distinctions occur<br />

with C rising Cglass O transition C C O<br />

n<br />

and melting temperatures. Processability<br />

by melting becomes increasingly difficult, and is<br />

H H<br />

then replaced by pressing methods, which are the preferred<br />

PET<br />

option for large-scale semi-finished product dimensions.<br />

A typical characteristic of this group of materials, which is<br />

classified as part of the thermoplastic high-temperature<br />

plastic group, is that its property profile is largely maintained<br />

Oalso in high-temperature<br />

O<br />

O<br />

ranges above O 100 °C; Most<br />

O<br />

characteristic C values C change only C moderately. C<strong>The</strong> most important<br />

N material and the one with N the -R most N technical uses<br />

C<br />

-R<br />

n<br />

is the polyetheretherketone C<br />

PEEK. C<br />

C<br />

C<br />

<strong>The</strong> materials O belonging to the O polyaryletherketone O group O<br />

are characterized by an unusually complex property profile<br />

PI<br />

with a large number of excellent individual characteristics.<br />

Properties<br />

ˌˌSemi-crystalline<br />

ˌˌLow density<br />

H H<br />

ˌˌHigh degree of toughness<br />

ˌˌHigh strength, hardness and rigidity<br />

ˌˌLow tendency to creep<br />

C H 3<br />

PMP<br />

C C<br />

n<br />

CH 2 H<br />

CH<br />

CH 3<br />

N<br />

POM-H PMP<br />

ˌˌGood sliding friction properties,<br />

good abrasion resistance<br />

ˌˌVery good chemical resistance to<br />

a wide range of technical media<br />

ˌˌHydrolysis resistance,<br />

tendency to stress crack formation<br />

ˌˌHigh thermal H H stability<br />

C C<br />

ˌˌUnusually high n radiation resistance<br />

H CH<br />

to gamma and 3<br />

X-rays<br />

ˌˌVery low moisture absorption<br />

PP<br />

ˌˌMinimal thermal expansion<br />

ˌˌGood dimensional stability<br />

ˌˌInherently flame resistant, self-extinguishing<br />

ˌˌMinimal ion contamination<br />

ˌˌVery low outgassing rates in high vacuum<br />

ˌˌMinimal, low-toxicity gas development<br />

CH 3<br />

in case of fire<br />

m<br />

CH<br />

Values<br />

3<br />

TECAPEEK TECAPEEK HT TECAPEEK ST<br />

PPO > PPE? (PEEK) (PEK) (PEKEKK)<br />

T g 150 °C 160 °C 165 °C<br />

PPS<br />

S<br />

O<br />

n<br />

n<br />

Density 1.31 g/cm³ 1.31 g/cm³ 1.32 g/cm³<br />

Modulus of elasticity 4,200 MPa 4,600 MPa 4,600 MPa<br />

Service temperature, long-term 260 °C 260 °C 260 °C<br />

Service temperature, short-term 300 °C 300 °C 300 °C<br />

Lower service temperature –40 °C –40 °C –40 °C<br />

(Exceptions down to –100 °C,<br />

increasing brittleness)<br />

36