Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

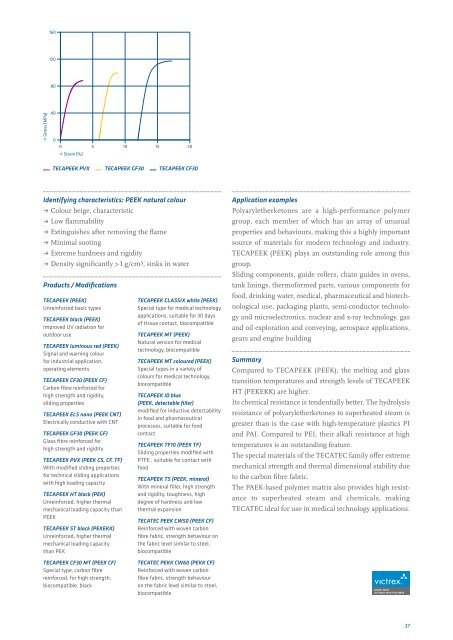

160<br />

120<br />

80<br />

• Stress [MPa]<br />

40<br />

0<br />

0 5 10 15<br />

20<br />

• Strain [%]<br />

TECAPEEK PVX<br />

TECAPEEK TECAPEEK PVX GF 30<br />

TECAPEEK CF 30<br />

TECAPEEK GF30 TECAPEEK CF30<br />

Identifying characteristics: PEEK natural colour<br />

ˌˌColour beige, characteristic<br />

ˌˌLow flammability<br />

ˌˌExtinguishes after removing the flame<br />

ˌˌMinimal sooting<br />

ˌˌExtreme hardness and rigidity<br />

ˌˌDensity significantly > 1 g/cm³, sinks in water<br />

Products / Modifications<br />

TECAPEEK (PEEK)<br />

Unreinforced basic types<br />

TECAPEEK black (PEEK)<br />

Improved UV radiation for<br />

outdoor use<br />

TECAPEEK luminous red (PEEK)<br />

Signal and warning colour<br />

for industrial application,<br />

operating elements<br />

TECAPEEK CF30 (PEEK CF)<br />

Carbon fibre reinforced for<br />

high strength and rigidity,<br />

sliding properties<br />

TECAPEEK ELS nano (PEEK CNT)<br />

Electrically conductive with CNT<br />

TECAPEEK GF30 (PEEK GF)<br />

Glass fibre reinforced for<br />

high strength and rigidity<br />

TECAPEEK PVX (PEEK CS, CF, TF)<br />

With modified sliding properties<br />

for technical sliding applications<br />

with high loading capacity<br />

TECAPEEK HT black (PEK)<br />

Unreinforced, higher thermal<br />

mechanical loading capacity than<br />

PEEK<br />

TECAPEEK ST black (PEKEKK)<br />

Unreinforced, higher thermal<br />

mechanical loading capacity<br />

than PEK<br />

TECAPEEK CF30 MT (PEEK CF)<br />

Special type, carbon fibre<br />

reinforced, for high strength,<br />

biocompatible, black<br />

TECAPEEK CLASSIX white (PEEK)<br />

Special type for medical technology<br />

applications, suitable for 30 days<br />

of tissue contact, biocompatible<br />

TECAPEEK MT (PEEK)<br />

Natural version for medical<br />

technology, biocompatible<br />

TECAPEEK MT coloured (PEEK)<br />

Special types in a variety of<br />

colours for medical technology,<br />

biocompatible<br />

TECAPEEK ID blue<br />

(PEEK, detectable filler)<br />

modified for inductive detectability<br />

in food and pharmaceutical<br />

processes, suitable for food<br />

contact<br />

TECAPEEK TF10 (PEEK TF)<br />

Sliding properties modified with<br />

PTFE , suitable for contact with<br />

food<br />

TECAPEEK TS (PEEK, mineral)<br />

With mineral filler, high strength<br />

and rigidity, toughness, high<br />

degree of hardness and low<br />

thermal expansion<br />

TECATEC PEEK CW50 (PEEK CF)<br />

Reinforced with woven carbon<br />

fibre fabric, strength behaviour on<br />

the fabric level similar to steel,<br />

biocompatible<br />

TECATEC PEKK CW60 (PEKK CF)<br />

Reinforced with woven carbon<br />

fibre fabric, strength behaviour<br />

on the fabric level similar to steel,<br />

biocompatible<br />

Application examples<br />

Polyaryletherketones are a high-performance polymer<br />

group, each member of which has an array of unusual<br />

properties and behaviours, making this a highly important<br />

source of materials for modern technology and industry.<br />

TECAPEEK (PEEK) plays an outstanding role among this<br />

group.<br />

Sliding components, guide rollers, chain guides in ovens,<br />

tank linings, thermoformed parts, various components for<br />

food, drinking water, medical, pharmaceutical and biotechnological<br />

use, packaging plants, semi-conductor technology<br />

and microelectronics, nuclear and x-ray technology, gas<br />

and oil exploration and conveying, aerospace applications,<br />

gears and engine building<br />

Summary<br />

Compared to TECAPEEK (PEEK), the melting and glass<br />

transition temperatures and strength levels of TECAPEEK<br />

HT (PEKEKK) are higher.<br />

Its chemical resistance is tendentially better. <strong>The</strong> hydrolysis<br />

resistance of polyaryletherketones to superheated steam is<br />

greater than is the case with high-temperature <strong>plastics</strong> PI<br />

and PAI. Compared to PEI, their alkali resistance at high<br />

temperatures is an outstanding feature.<br />

<strong>The</strong> special materials of the TECATEC family offer extreme<br />

mechanical strength and thermal dimensional stability due<br />

to the carbon fibre fabric.<br />

<strong>The</strong> PAEK-based polymer matrix also provides high resistance<br />

to superheated steam and chemicals, making<br />

TECATEC ideal for use in medical technology applications.<br />

37