Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

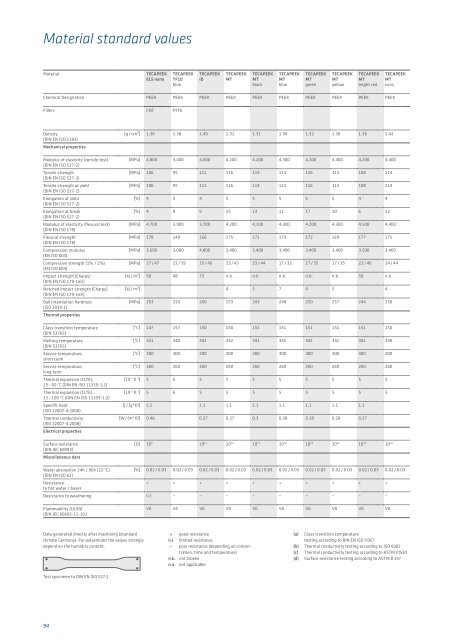

Material standard values<br />

Material<br />

TECAPEEK<br />

ELS nano<br />

TECAPEEK<br />

TF10<br />

blue<br />

TECAPEEK<br />

ID<br />

TECAPEEK<br />

MT<br />

TECAPEEK<br />

MT<br />

black<br />

TECAPEEK<br />

MT<br />

blue<br />

TECAPEEK<br />

MT<br />

green<br />

TECAPEEK<br />

MT<br />

yellow<br />

TECAPEEK<br />

MT<br />

bright red<br />

TECAPEEK<br />

MT<br />

ivory<br />

Chemical Designation<br />

PEEK PEEK PEEK PEEK PEEK PEEK PEEK PEEK PEEK PEEK<br />

Fillers<br />

CNT<br />

PTFE<br />

Density<br />

(DIN EN ISO 1183)<br />

Mechanical properties<br />

Modulus of elasticity (tensile test)<br />

(DIN EN ISO 527-2)<br />

Tensile strength<br />

(DIN EN ISO 527-2)<br />

Tensile strength at yield<br />

(DIN EN ISO 527-2)<br />

Elongation at yield<br />

(DIN EN ISO 527-2)<br />

Elongation at break<br />

(DIN EN ISO 527-2)<br />

Modulus of elasticity (flexural test)<br />

(DIN EN ISO 178)<br />

Flexural strength<br />

(DIN EN ISO 178)<br />

Compression modulus<br />

(EN ISO 604)<br />

Compressive strength (1% / 2%)<br />

(EN ISO 604)<br />

Impact strength (Charpy)<br />

(DIN EN ISO 179-1eU)<br />

Notched impact strength (Charpy)<br />

(DIN EN ISO 179-1eA)<br />

Ball intendation hardness<br />

(ISO 2039-1)<br />

<strong>The</strong>rmal properties<br />

Glass transition temperature<br />

(DIN 53765)<br />

Melting temperature<br />

(DIN 53765)<br />

Service temperature,<br />

short term<br />

Service temperature,<br />

long term<br />

<strong>The</strong>rmal expansion (CLTE),<br />

23 – 60 °C (DIN EN ISO 11359-1;2)<br />

<strong>The</strong>rmal expansion (CLTE),<br />

23 – 100 °C (DIN EN ISO 11359-1;2)<br />

Specific heat<br />

(ISO 22007-4:2008)<br />

<strong>The</strong>rmal conductivity<br />

(ISO 22007-4:2008)<br />

Electrical properties<br />

Surface resistance<br />

(DIN IEC 60093)<br />

Miscellaneous data<br />

Water absorption 24h / 96h (23 °C)<br />

(DIN EN ISO 62)<br />

Resistance<br />

to hot water / bases<br />

Resistance to weathering<br />

Flammability (UL94)<br />

(DIN IEC 60695-11-10;)<br />

[g / cm³]<br />

[MPa]<br />

[MPa]<br />

[MPa]<br />

[%]<br />

[%]<br />

[MPa]<br />

[MPa]<br />

[MPa]<br />

[MPa]<br />

[kJ / m²]<br />

[kJ / m²]<br />

[MPa]<br />

[°C]<br />

[°C]<br />

[°C]<br />

[°C]<br />

[10 -5 K -1 ]<br />

[10 -5 K -1 ]<br />

[J / (g*K)]<br />

[W/(m*K)]<br />

[Ω]<br />

[%]<br />

1.36 1.38 1.49 1.31 1.31 1.34 1.32 1.38 1.36 1.42<br />

4,800 3,400 4,600 4,200 4,200 4,300 4,100 4,400 4,200 4,400<br />

106 95 111 116 114 113 116 113 108 114<br />

106 95 111 116 114 113 116 113 108 114<br />

4 5 4 5 5 5 5 5 4 4<br />

4 8 6 15 13 11 17 10 6 12<br />

4,700 3,900 3,700 4,200 4,100 4,300 4,200 4,300 4,500 4,400<br />

178 149 166 175 171 173 172 169 177 171<br />

3,600 3,000 4,800 3,400 3,400 3,400 3,400 3,400 3,500 3,400<br />

27 / 47 22 / 39 25 / 46 23 / 43 23 / 44 17 / 35 17 / 35 17 / 35 22 / 40 24 / 44<br />

58 48 72 n.b. n.b. n.b. n.b. n.b. 50 n.b.<br />

4 5 7 4 5 4<br />

253 220 260 253 243 248 250 257 244 250<br />

147 157 150 150 151 151 151 151 151 150<br />

341 340 341 342 341 341 341 341 341 340<br />

300 300 300 300 300 300 300 300 300 300<br />

260 260 260 260 260 260 260 260 260 260<br />

5 6 5 5 5 5 5 5 5 5<br />

5 6 5 5 5 5 5 5 5 5<br />

1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1<br />

0.46 0.27 0.27 0.3 0.28 0.28 0.28 0.27<br />

10 4 10 13 10 14 10 12 10 14 10 14 10 14 10 14 10 14<br />

0.02 / 0.03 0.02 / 0.03 0.02 / 0.03 0.02 / 0.03 0.02 / 0.03 0.02 / 0.03 0.02 / 0.03 0.02 / 0.03 0.02 / 0.03 0.02 / 0.03<br />

+ + + + + + + + + +<br />

(+) – – – – – – – – –<br />

V0 V0 V0 V0 V0 V0 V0 V0 V0 V0<br />

Data generated directly after machining (standard<br />

climate Germany). For polyamides the values strongly<br />

depend on the humidity content.<br />

Test specimen to DIN EN ISO 527-2<br />

+ good resistance<br />

(+) limited resistance<br />

– poor resistance (depending on concen -<br />

tration, time and temperature)<br />

n.b. not broken<br />

n.a. not applicable<br />

(a) Glass transition temperature<br />

testing according to DIN EN ISO 11357<br />

(b) <strong>The</strong>rmal conductivity testing according to ISO 8302<br />

(c) <strong>The</strong>rmal conductivity testing according to ASTM E1530<br />

(d) Surface resistance testing according to ASTM D 257<br />

94