Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

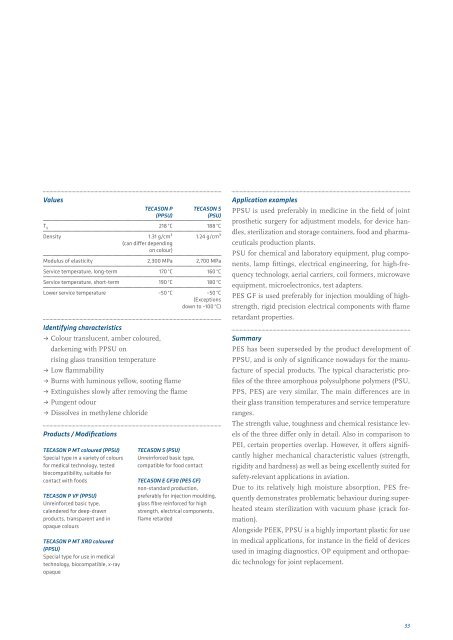

Values<br />

TECASON P<br />

(PPSU)<br />

TECASON S<br />

(PSU)<br />

T g 218 °C 188 °C<br />

Density 1.31 g/cm³ 1.24 g/cm³<br />

(can differ depending<br />

on colour)<br />

Modulus of elasticity 2,300 MPa 2,700 MPa<br />

Service temperature, long-term 170 °C 160 °C<br />

Service temperature, short-term 190 °C 180 °C<br />

Lower service temperature –50 °C –50 °C<br />

(Exceptions<br />

<br />

down to –100 °C)<br />

Identifying characteristics<br />

ˌˌColour translucent, amber coloured,<br />

darkening with PPSU on<br />

rising glass transition temperature<br />

ˌˌLow flammability<br />

ˌˌBurns with luminous yellow, sooting flame<br />

ˌˌExtinguishes slowly after removing the flame<br />

ˌˌPungent odour<br />

ˌˌDissolves in methylene chloride<br />

Products / Modifications<br />

TECASON P MT coloured (PPSU)<br />

Special type in a variety of colours<br />

for medical technology, tested<br />

biocompatibility, suitable for<br />

contact with foods<br />

TECASON P VF (PPSU)<br />

Unreinforced basic type,<br />

calendered for deep-drawn<br />

products, transparent and in<br />

opaque colours<br />

TECASON P MT XRO coloured<br />

(PPSU)<br />

Special type for use in medical<br />

technology, biocompatible, x-ray<br />

opaque<br />

TECASON S (PSU)<br />

Unreinforced basic type,<br />

compatible for food contact<br />

TECASON E GF30 (PES GF)<br />

non-standard production,<br />

preferably for injection moulding,<br />

glass fibre reinforced for high<br />

strength, electrical components,<br />

flame retarded<br />

Application examples<br />

PPSU is used preferably in medicine in the field of joint<br />

prosthetic surgery for adjustment models, for device handles,<br />

sterilization and storage containers, food and pharmaceuticals<br />

production plants.<br />

PSU for chemical and laboratory equipment, plug components,<br />

lamp fittings, electrical engineering, for high-frequency<br />

technology, aerial carriers, coil formers, microwave<br />

equipment, microelectronics, test adapters.<br />

PES GF is used preferably for injection moulding of highstrength,<br />

rigid precision electrical components with flame<br />

retardant properties.<br />

Summary<br />

PES has been superseded by the product development of<br />

PPSU, and is only of significance nowadays for the manufacture<br />

of special products. <strong>The</strong> typical characteristic profiles<br />

of the three amorphous polysulphone polymers (PSU,<br />

PPS, PES) are very similar. <strong>The</strong> main differences are in<br />

their glass transition temperatures and service temperature<br />

ranges.<br />

<strong>The</strong> strength value, toughness and chemical resistance levels<br />

of the three differ only in detail. Also in comparison to<br />

PEI, certain properties overlap. However, it offers significantly<br />

higher mechanical characteristic values (strength,<br />

rigidity and hardness) as well as being excellently suited for<br />

safety-relevant applications in aviation.<br />

Due to its relatively high moisture absorption, PES frequently<br />

demonstrates problematic behaviour during superheated<br />

steam sterilization with vacuum phase (crack formation).<br />

Alongside PEEK, PPSU is a highly important plastic for use<br />

in medical applications, for instance in the field of devices<br />

used in imaging diagnostics, OP equipment and orthopaedic<br />

technology for joint replacement.<br />

33