Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

Engineering plastics â The Manual - F.wood-supply.dk

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Mechanical properties<br />

σ R<br />

0<br />

σ B<br />

σ R<br />

σ S<br />

σ R<br />

Where plastic components are designed to withstand<br />

stress, the mechanical characteristics of a material have a<br />

particularly important role to play. <strong>The</strong> fundamental mechanical<br />

material properties include<br />

Δ σ<br />

Δ ε<br />

ˌˌStrength: dimension for the resistance<br />

of a material to external stress<br />

ˌˌFormability: the capacity of a material<br />

to become deformed under external stress<br />

ˌˌRigidity: ε R<br />

ε S dimension for the resistance ε B<br />

ε R<br />

ε R<br />

of a material to deformation<br />

ˌˌToughness: dimension for the energy absorption<br />

capacity of a material under external stress<br />

ˌˌTensile strength at yield σ S is the tensile stress at which<br />

the slope of the change of force versus length curve (see<br />

graph) equals zero for the first time.<br />

ε<br />

ˌˌElongation ε is the change in length Δ L in relation to the<br />

σ B original length L<br />

σ 0 of the specimen at any point during ε el(0)<br />

R<br />

σ testing. <strong>The</strong> elongation at maximum force is described<br />

S<br />

as ε B , elongation at break as ε R , tensile strength εat el(t)<br />

yield<br />

as ε S . ε = ε el(0)<br />

+ε el(t)<br />

+ε pl<br />

ˌˌModulus of elasticity E: A linear relationship can εonly pl be<br />

σ R<br />

observed in the lower range of the stress-strain diagram<br />

for <strong>plastics</strong>. In this range Hooke’s law applies, which<br />

says that the ratio of the stress and strain (modulus of<br />

elasticity) is constant. E = σ / ε in [MPa].<br />

ε<br />

σ<br />

S Strength<br />

F FormabilityF<br />

R Rigidity<br />

T Toughness<br />

V<br />

σ<br />

S<br />

F<br />

σ R<br />

0<br />

Δ σ<br />

ε S<br />

ε B<br />

ε R<br />

ε R<br />

Δ ε<br />

ε R<br />

Based on the bending, compression and impact toughness<br />

test, additional test methods are available for characterizing<br />

materials and different load cases.<br />

σ<br />

S<br />

R<br />

Z<br />

T<br />

ε<br />

0<br />

ε<br />

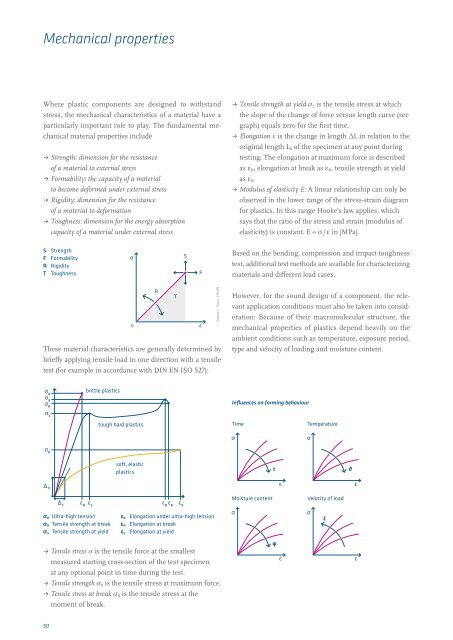

<strong>The</strong>se material characteristics are generally determined by<br />

briefly applying tensile load in one direction with a tensile<br />

test (for example in accordance with DIN EN ISO 527):<br />

σ<br />

brittle <strong>plastics</strong><br />

Source: J. Kunz, FHNW<br />

However, for the sound design of a component, the rele-<br />

application conditions F must also σ be taken into consid-<br />

S<br />

σvant<br />

eration: Because of their macromolecular structure, the<br />

V<br />

F<br />

mechanical properties of <strong>plastics</strong> depend heavily on the<br />

ambient conditions such as temperature, exposure period,<br />

S<br />

R<br />

type and velocity Z of loading and moisture content. T<br />

ε<br />

0<br />

ε<br />

σ B<br />

σ R<br />

Influences on forming behaviour<br />

σ S<br />

t<br />

ε<br />

ϑ<br />

tough hard <strong>plastics</strong><br />

ε<br />

Time<br />

σ<br />

ε<br />

Temperature<br />

σ<br />

σ R<br />

ε el(0)<br />

σ<br />

σ<br />

soft, elastic<br />

έ<br />

<strong>plastics</strong><br />

t<br />

ϑ<br />

ε el(t)<br />

Δ σ<br />

ε S<br />

ε B<br />

ε R<br />

ε R<br />

φ<br />

Δ ε ε R<br />

ε<br />

σ B Ultra-high tension<br />

σ R Tensile strength at break<br />

σ S Tensile strength at yield<br />

ε<br />

ε B Elongation under ultra-high tension<br />

ε R Elongation at break<br />

ε S Elongation at yield<br />

Moisture content<br />

σ<br />

ε<br />

ε = ε el(0)<br />

+ε el(t)<br />

+ε pl<br />

Velocity of load<br />

σ<br />

έ<br />

ε<br />

ε pl<br />

ˌˌTensile stress σ is the tensile force at the smallest<br />

σmeasured starting F cross-section of σthe test specimen S<br />

at any optional point in time during the test.<br />

V<br />

ˌˌTensile strength σ B is the tensile stress at maximum force.<br />

ˌˌTensile stress S at break σ R is the tensile stress Rat the<br />

Z<br />

T<br />

moment of break.<br />

F<br />

φ<br />

ε<br />

ε<br />

σ R<br />

0<br />

50<br />

ε<br />

0<br />

ε