Part 1 3.7.qxp - Southwestern Oregon Community College

Part 1 3.7.qxp - Southwestern Oregon Community College

Part 1 3.7.qxp - Southwestern Oregon Community College

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

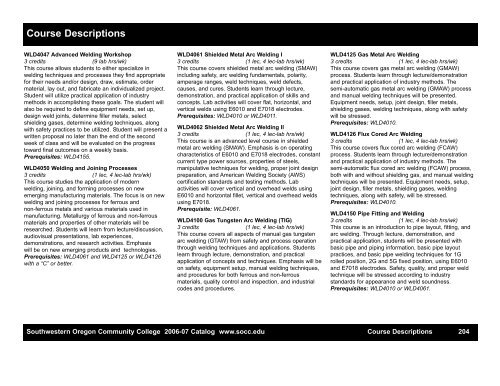

Course Descriptions<br />

WLD4047 Advanced Welding Workshop<br />

3 credits (9 lab hrs/wk)<br />

This course allows students to either specialize in<br />

welding techniques and processes they find appropriate<br />

for their needs and/or design, draw, estimate, order<br />

material, lay out, and fabricate an individualized project.<br />

Student will utilize practical application of industry<br />

methods in accomplishing these goals. The student will<br />

also be required to define equipment needs, set up,<br />

design weld joints, determine filler metals, select<br />

shielding gases, determine welding techniques, along<br />

with safety practices to be utilized. Student will present a<br />

written proposal no later than the end of the second<br />

week of class and will be evaluated on the progress<br />

toward final outcomes on a weekly basis.<br />

Prerequisites: WLD4155.<br />

WLD4050 Welding and Joining Processes<br />

3 credits (1 lec, 4 lec-lab hrs/wk)<br />

This course studies the application of modern<br />

welding, joining, and forming processes on new<br />

emerging manufacturing materials. The focus is on new<br />

welding and joining processes for ferrous and<br />

non-ferrous metals and various materials used in<br />

manufacturing. Metallurgy of ferrous and non-ferrous<br />

materials and properties of other materials will be<br />

researched. Students will learn from lecture/discussion,<br />

audiovisual presentations, lab experiences,<br />

demonstrations, and research activities. Emphasis<br />

will be on new emerging products and technologies.<br />

Prerequisites: WLD4061 and WLD4125 or WLD4126<br />

with a “C” or better.<br />

WLD4061 Shielded Metal Arc Welding I<br />

3 credits (1 lec, 4 lec-lab hrs/wk)<br />

This course covers shielded metal arc welding (SMAW)<br />

including safety, arc welding fundamentals, polarity,<br />

amperage ranges, weld techniques, weld defects,<br />

causes, and cures. Students learn through lecture,<br />

demonstration, and practical application of skills and<br />

concepts. Lab activities will cover flat, horizontal, and<br />

vertical welds using E6010 and E7018 electrodes.<br />

Prerequisites: WLD4010 or WLD4011.<br />

WLD4062 Shielded Metal Arc Welding II<br />

3 credits (1 lec, 4 lec-lab hrs/wk)<br />

This course is an advanced level course in shielded<br />

metal arc welding (SMAW). Emphasis is on operating<br />

characteristics of E6010 and E7018 electrodes, constant<br />

current type power sources, properties of steels,<br />

manipulative techniques for welding, proper joint design<br />

preparation, and American Welding Society (AWS)<br />

certification standards and testing methods. Lab<br />

activities will cover vertical and overhead welds using<br />

E6010 and horizontal fillet, vertical and overhead welds<br />

using E7018.<br />

Prerequisite: WLD4061.<br />

WLD4100 Gas Tungsten Arc Welding (TIG)<br />

3 credits (1 lec, 4 lec-lab hrs/wk)<br />

This course covers all aspects of manual gas tungsten<br />

arc welding (GTAW) from safety and process operation<br />

through welding techniques and applications. Students<br />

learn through lecture, demonstration, and practical<br />

application of concepts and techniques. Emphasis will be<br />

on safety, equipment setup, manual welding techniques,<br />

and procedures for both ferrous and non-ferrous<br />

materials, quality control and inspection, and industrial<br />

codes and procedures.<br />

WLD4125 Gas Metal Arc Welding<br />

3 credits (1 lec, 4 lec-lab hrs/wk)<br />

This course covers gas metal arc welding (GMAW)<br />

process. Students learn through lecture/demonstration<br />

and practical application of industry methods. The<br />

semi-automatic gas metal arc welding (GMAW) process<br />

and manual welding techniques will be presented.<br />

Equipment needs, setup, joint design, filler metals,<br />

shielding gases, welding techniques, along with safety<br />

will be stressed.<br />

Prerequisites: WLD4010.<br />

WLD4126 Flux Cored Arc Welding<br />

3 credits (1 lec, 4 lec-lab hrs/wk)<br />

This course covers flux cored arc welding (FCAW)<br />

process. Students learn through lecture/demonstration<br />

and practical application of industry methods. The<br />

semi-automatic flux cored arc welding (FCAW) process,<br />

both with and without shielding gas, and manual welding<br />

techniques will be presented. Equipment needs, setup,<br />

joint design, filler metals, shielding gases, welding<br />

techniques, along with safety, will be stressed.<br />

Prerequisites: WLD4010.<br />

WLD4150 Pipe Fitting and Welding<br />

3 credits (1 lec, 4 lec-lab hrs/wk)<br />

This course is an introduction to pipe layout, fitting, and<br />

arc welding. Through lecture, demonstration, and<br />

practical application, students will be presented with<br />

basic pipe and piping information, basic pipe layout<br />

practices, and basic pipe welding techniques for 1G<br />

rolled position, 2G and 5G fixed position, using E6010<br />

and E7018 electrodes. Safety, quality, and proper weld<br />

technique will be stressed according to industry<br />

standards for appearance and weld soundness.<br />

Prerequisites: WLD4010 or WLD4061.<br />

<strong>Southwestern</strong> <strong>Oregon</strong> <strong>Community</strong> <strong>College</strong> 2006-07 Catalog www.socc.edu Course Descriptions 204

![SWOCC Viewbook [PDF] - Southwestern Oregon Community College](https://img.yumpu.com/26373688/1/190x245/swocc-viewbook-pdf-southwestern-oregon-community-college.jpg?quality=85)