equipment sourcebook - Loctite.ph

equipment sourcebook - Loctite.ph

equipment sourcebook - Loctite.ph

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Loctite</strong> ® Posi-Link Dispense System<br />

for Prepackaged Syringes<br />

the<br />

DISPENSING<br />

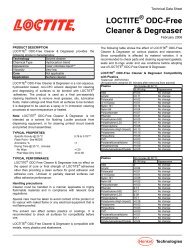

The <strong>Loctite</strong>® Posi-Link Dispensing System is a programmable, volumetric dispense<br />

system that is designed to provide the highest level of dispensing precision directly<br />

from a disposable syringe barrel. No need to worry about product temperature or<br />

product viscosity changes. This innovative, patent pending design utilizes a<br />

“positive link” between a step motor and a mechanical plunger via a noncompressible<br />

hydraulic fluid, to ensure precise adhesive dispensing down to<br />

0.001 ml drop sizes. See Theory of Operation, page 10.<br />

COMPLETE LOCTITE ® POSI-LINK SYRINGE SYSTEM<br />

AGE<br />

of Volumetric Control<br />

The END of wetted<br />

components and adhesive<br />

downloading<br />

Dispense Systems<br />

<strong>Loctite</strong> ® Posi-Link <br />

Syringe System<br />

Controller + Actuator + Nest<br />

LOCTITE ® POSI-LINK CONTROLLER<br />

Item Number: 98377<br />

Provides all operator interface and<br />

control signals to actuator.<br />

Features:<br />

(Each Item Sold Separately)<br />

• Dose selection by volume<br />

• Easy programming controller, with<br />

storage capacity for 25 user defined<br />

programs, reduces adhesive set-up waste<br />

• Smallest footprint on the market to conserve benchtop space<br />

• Automatic syringe engagement to ensure<br />

easy and error-free syringe changeover<br />

• Adhesive level monitoring with low level visual and digital outputs<br />

• Fault detection with visual and digital outputs for clogged nozzles,<br />

loss of pressure, and system faults<br />

• In- cycle visual and digital outputs<br />

• Foot switch, finger switch or PLC remote start activation<br />

LOCTITE ® POSI-LINK ACTUATORS<br />

Item Numbers: See chart<br />

Provides adhesive dispensing by effecting incremental<br />

movements of syringe piston and displacing programmable<br />

quantities of adhesive within syringe barrel.<br />

Features:<br />

• Flexible orientation in any position<br />

• Easily fits below an industrial workbench or wall mounts<br />

with brackets supplied to conserve benchtop space<br />

• Lightweight remote dispense head has a “positive link” to<br />

actuator via a 7 foot tether, allowing ergonomic hand held<br />

dispensing or mounting directly on robotic arms<br />

• Easily attaches to syringe nest (sold separately)<br />

to accommodate alternate syringe barrel sizes<br />

• Adhesive Pressure: Mechanically driven vs. traditional<br />

air pressure driven, eliminating risk of air infiltration<br />

into adhesive<br />

• Suck-Back: Prevents drip at end of dispense, and is mechanical<br />

driven vs. traditional air vacuum driven, eliminating risk of<br />

adhesive being sucked into the system<br />

Compact controller and floor mounted actuator<br />

leaves benchtop wide open for manual applications.<br />

See pages 30-31 for more information on<br />

<strong>Loctite</strong> ® Posi-Link for dual cartridge applications.<br />

PRODUCT<br />

<strong>Loctite</strong> ®<br />

Posi-Link <br />

5-25 Actuator<br />

<strong>Loctite</strong> ®<br />

Posi-Link <br />

10-50 Actuator<br />

Item Number 98378 98379 ‡<br />

Application<br />

Type<br />

Syringe<br />

Barrel Size<br />

Recommended<br />

for Hand Held<br />

Recommended<br />

for Mounted<br />

or Robotic<br />

5, 10, 25 ml 10, 25 ml<br />

‡ See pages 30-31 for use with dual component<br />

epoxy cartridges.<br />

For additional information and the full line of <strong>equipment</strong>, visit www.<strong>equipment</strong>.loctite.com.<br />

9