equipment sourcebook - Loctite.ph

equipment sourcebook - Loctite.ph

equipment sourcebook - Loctite.ph

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Valves & Pumps<br />

DISPENSING<br />

HIGH VISCOSITY FLUID AND PASTE VALVES<br />

LOCTITE ® POPPET VALVES Item Numbers: 986300 and 983914<br />

LOCTITE ® STAINLESS STEEL POPPET VALVE Item Number: 982621<br />

The <strong>Loctite</strong>® Poppet Valves are designed to dispense <strong>Loctite</strong>® brand high viscosity<br />

anaerobic form-in-place gasketing products, structural acrylics, and silicones. The valves are<br />

typically used in conjunction with a positive displacement pump or a pressure-time system.<br />

They feature a suck-back capability and can operate at fluid pressures up to 625 psi. Item<br />

986300 uses dispense nozzles with a bayonet style mounting that improves nozzle end<br />

location and can withstand the high fluid pressures required of high viscosity fluid<br />

dispensing. Items 983914 and 982621 are equipped with a 1 ⁄8" NPT outlet for Luer-Lok® and<br />

standard needle dispensing. All valves have stroke adjustment capability and are treated<br />

with a proprietary <strong>Loctite</strong>® coating to prevent premature adhesive curing.<br />

Features:<br />

• Poppet design gives valve “suck-back” feature<br />

• Bayonet type mounting of nozzles provides end location repeatability<br />

• Handles product pressures up to 625 psi<br />

• Positive mounting surface<br />

• High strength plastic material versions are specially treated<br />

to be inert to <strong>Loctite</strong>® brand products<br />

• Stainless steel version is also specially treated and<br />

is recommended for abrasive and silicone products<br />

982621 – <strong>Loctite</strong> ® Stainless<br />

Steel Poppet Valve<br />

986300 and 983914 –<br />

<strong>Loctite</strong> ® Poppet Valves<br />

Theory of Operation<br />

Use the <strong>Loctite</strong>® Poppet Valve to apply product in drops and<br />

beads with a semi or fully automatic dispensing system. The<br />

valve can be used in both the stationary or advancing modes.<br />

They may be used with the <strong>Loctite</strong>® Pump-A-Bead II or any<br />

other dispense system that can provide a source of pressurized<br />

product and a 4-way pneumatic valve.<br />

NO FLOW<br />

The RED represents the fluid path.<br />

FLOW<br />

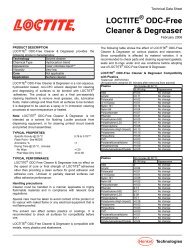

TECHNICAL SPECIFICATIONS<br />

Type<br />

High Viscosity Fluids and Pastes<br />

Viscosity Range<br />

Medium to High anaerobics up to<br />

Low Viscosity silicone products<br />

Size<br />

5.28" H x 2.00" D<br />

Weight<br />

1.3 lb. (0.59 kg) valve plus fittings and tubing<br />

Maximum Fluid Pressure<br />

Should not exceed 625 psi<br />

Air Input<br />

60 psi<br />

Inlet<br />

1 ⁄4" NPT<br />

Dispense Tip Style 986300: Bayonet Style<br />

983914 and 982621: 1 ⁄8" NPT for<br />

Luer-Lok ® dispense tips<br />

Used to Dispense<br />

Anaerobic Gasketing,<br />

Retaining Compounds, Modified Silanes, Silicones<br />

Threadlockers<br />

Dispense Patterns<br />

Bead, Drop<br />

Stroke Adjustment<br />

Yes<br />

Suck-Back<br />

Yes<br />

Valve Type<br />

Pressure-Time Dispense<br />

Wetted Components Acetal Copolymer treated with a proprietary <strong>Loctite</strong> ® brand process<br />

Parts Included (1) Acetal Copolymer Body or Stainless Steel Poppet Valve with:<br />

(2) 4' Control Air Tubing (1) 4' Product Supply Tubing<br />

(1) Accessory Kit (1) Manual<br />

Additional Information For Spare Parts and Bayonet type needles, see pages 84-85.<br />

For Fluid Compatibility Selector Chart, see pages 74-75.<br />

For Luer-Lok ® Dispense Tips, see pages 80-81.<br />

Additional Accessories Sold Separately<br />

984691 –<br />

986000 –<br />

Pump-A-Bead Slide (2" Stroke)<br />

<strong>Loctite</strong> ®<br />

<strong>Loctite</strong> ® Advancing<br />

70<br />

For additional information and the full line of <strong>equipment</strong>, visit www.<strong>equipment</strong>.loctite.com.