equipment sourcebook - Loctite.ph

equipment sourcebook - Loctite.ph

equipment sourcebook - Loctite.ph

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DISPENSING<br />

Two-Part Volumetric<br />

Dispensing<br />

Meter Mix Systems<br />

LOCTITE ® METER MIX 1000 DISPENSE SYSTEM – OPERATOR TRIGGER CONTROL<br />

Item Numbers: 988900, 988901, 988902 and 988903<br />

The <strong>Loctite</strong>® Meter Mix 1000 Dispense Systems are versatile<br />

dispensing systems for two-part adhesive chemistries and<br />

incorporate a variety of feed system options. Available in fixed<br />

or variable ratio, the compact design of the systems allows<br />

benchtop dispensing. These machines come standard to accept<br />

a hand held dispense valve (sold separately). Flow rate is<br />

adjustable through the use of a pressure regulator. See technical<br />

specifications for shot size and mix ratio ranges.<br />

Features:<br />

• Variable mix ratio capability<br />

• Ratio check valves<br />

• Adjustable flow control<br />

• Mild steel or abrasion resistance pumps available<br />

• Operator controlled shot size<br />

Theory of Operation<br />

The <strong>Loctite</strong>® Meter Mix 1000 Dispense Systems accurately<br />

meter dual liquid and semi-solid materials throughout<br />

a wide range of viscosities and ratios. They contain two high<br />

precision, volumetric displacement pump assemblies.<br />

Selectable paired pump diameters determine the ratio for<br />

a fixed system. The variable ratio unit utilizes a pneumatic<br />

cylinder to adjust a lever-beam drive link to automatically<br />

change ratio requirements. Dispensing is controlled using<br />

a pneumatically controlled valve to open (sold separately).<br />

Shot size is controlled using a manual vernier selector switch<br />

and 4-digit reference. Both liquids move simultaneously<br />

through two dispensing hoses, a dispense valve and mixing<br />

chamber/static mixer that provide the effective mixing of the<br />

two components just prior to being applied.<br />

Fixed<br />

Variable<br />

Utilities<br />

Dimensions<br />

Weight<br />

Dispense Range/Cycle<br />

Cycle Rate<br />

Mix Ratio Range<br />

by Volume<br />

Used to Dispense<br />

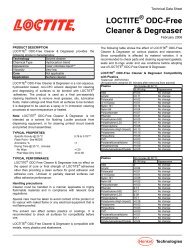

TECHNICAL SPECIFICATIONS<br />

Low Flow System 1000L 988900<br />

High Flow System 1000H 988902<br />

Low Flow System 1000L 988901<br />

High Flow System 1000H 988903<br />

Pneumatic: 80 to 100 psi<br />

20.0" H x 15.0" W x 28.0" D<br />

75 to 100 lbs.<br />

FIXED – 0.51 cc to 25 cc<br />

VARIABLE – 0.51 cc to 21.37 cc<br />

Up to 30 or more per minute, depending on material<br />

viscosity, hose sizes, and mixer type<br />

FIXED – 1:1 to 9.76:1<br />

VARIABLE – 1:1 to 41.56:1<br />

Two-Part Epoxies, Two-Part Acrylics, Two-Part Polyurethanes<br />

Package Types<br />

Cans, pails, drums, totes<br />

Parts Included (1) <strong>Loctite</strong> ® 1000 Meter Mix System – Choice of either<br />

8, 10, 15, 20, 25, 30 or 35 mm pump assemblies<br />

(depends on ratio and dispense rate requirements)*<br />

(1) Pump Mode Off/On pneumatic selector switch<br />

(10) Static Mixers (1) Night Cap (1) Ratio Cap<br />

Additional Information **Feed system options and accessories are sold separately<br />

and can be found on pages 39-40.<br />

*See pages 41-42 to determine pump diameters<br />

required for your application.<br />

Additional Accessories Sold Separately**<br />

• Material reservoirs • Dispense valves • Abrasive resistant<br />

• Level sensors • Follower plates wetted components<br />

• Reservoir heaters • Desiccant dryers • All 316 stainless steel<br />

• Hoses – various sizes • Lock down lid wetted components<br />

and lengths with agitator for MMAs<br />

For additional information and the full line of <strong>equipment</strong>, visit www.<strong>equipment</strong>.loctite.com.<br />

35