equipment sourcebook - Loctite.ph

equipment sourcebook - Loctite.ph

equipment sourcebook - Loctite.ph

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

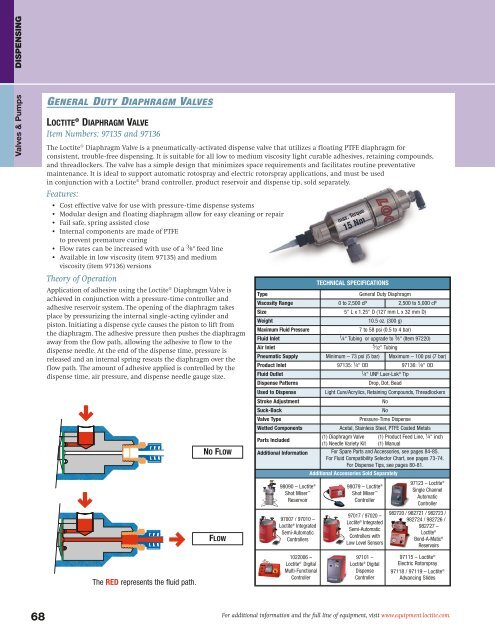

DISPENSING<br />

Valves & Pumps<br />

GENERAL DUTY DIAPHRAGM VALVES<br />

LOCTITE ® DIAPHRAGM VALVE<br />

Item Numbers: 97135 and 97136<br />

The <strong>Loctite</strong>® Dia<strong>ph</strong>ragm Valve is a pneumatically-activated dispense valve that utilizes a floating PTFE dia<strong>ph</strong>ragm for<br />

consistent, trouble-free dispensing. It is suitable for all low to medium viscosity light curable adhesives, retaining compounds,<br />

and threadlockers. The valve has a simple design that minimizes space requirements and facilitates routine preventative<br />

maintenance. It is ideal to support automatic rotospray and electric rotorspray applications, and must be used<br />

in conjunction with a <strong>Loctite</strong>® brand controller, product reservoir and dispense tip, sold separately.<br />

Features:<br />

• Cost effective valve for use with pressure-time dispense systems<br />

• Modular design and floating dia<strong>ph</strong>ragm allow for easy cleaning or repair<br />

• Fail safe, spring assisted close<br />

• Internal components are made of PTFE<br />

to prevent premature curing<br />

• Flow rates can be increased with use of a 3 ⁄8" feed line<br />

• Available in low viscosity (item 97135) and medium<br />

viscosity (item 97136) versions<br />

Theory of Operation<br />

Application of adhesive using the <strong>Loctite</strong>® Dia<strong>ph</strong>ragm Valve is<br />

achieved in conjunction with a pressure-time controller and<br />

adhesive reservoir system. The opening of the dia<strong>ph</strong>ragm takes<br />

place by pressurizing the internal single -acting cylinder and<br />

piston. Initiating a dispense cycle causes the piston to lift from<br />

the dia<strong>ph</strong>ragm. The adhesive pressure then pushes the dia<strong>ph</strong>ragm<br />

away from the flow path, allowing the adhesive to flow to the<br />

dispense needle. At the end of the dispense time, pressure is<br />

released and an internal spring reseats the dia<strong>ph</strong>ragm over the<br />

flow path. The amount of adhesive applied is controlled by the<br />

dispense time, air pressure, and dispense needle gauge size.<br />

NO FLOW<br />

Type<br />

TECHNICAL SPECIFICATIONS<br />

General Duty Dia<strong>ph</strong>ragm<br />

Viscosity Range 0 to 2,500 cP 2,500 to 5,000 cP<br />

Size 5" L x 1.25" D (127 mm L x 32 mm D)<br />

Weight 10.5 oz. (300 g)<br />

Maximum Fluid Pressure<br />

7 to 58 psi (0.5 to 4 bar)<br />

Fluid Inlet 1 ⁄4" Tubing or upgrade to 3 ⁄8" (Item 97220)<br />

Air Inlet<br />

5 ⁄32" Tubing<br />

Pneumatic Supply Minimum – 73 psi (5 bar) Maximum – 100 psi (7 bar)<br />

Product Inlet 97135: 1 ⁄4" OD 97136: 1 ⁄8" OD<br />

Fluid Outlet<br />

Dispense Patterns<br />

Used to Dispense<br />

Stroke Adjustment<br />

Suck-Back<br />

Valve Type<br />

Wetted Components<br />

1 ⁄4" UNF Luer-Lok ® Tip<br />

Drop, Dot, Bead<br />

Light Cure/Acrylics, Retaining Compounds, Threadlockers<br />

No<br />

No<br />

Pressure-Time Dispense<br />

Acetal, Stainless Steel, PTFE Coated Metals<br />

(1) Dia<strong>ph</strong>ragm Valve (1) Product Feed Line,<br />

Parts Included<br />

1 ⁄4" inch<br />

(1) Needle Variety Kit (1) Manual<br />

Additional Information For Spare Parts and Accessories, see pages 84-85.<br />

For Fluid Compatibility Selector Chart, see pages 73-74.<br />

For Dispense Tips, see pages 80-81.<br />

Additional Accessories Sold Separately<br />

98090 – <strong>Loctite</strong> ®<br />

Shot Miser <br />

Reservoir<br />

98079 – <strong>Loctite</strong> ®<br />

Shot Miser <br />

Controller<br />

97123 – <strong>Loctite</strong> ®<br />

Single Channel<br />

Automatic<br />

Controller<br />

FLOW<br />

97007 / 97010 –<br />

<strong>Loctite</strong> ® Integrated<br />

Semi-Automatic<br />

Controllers<br />

97017 / 97020 –<br />

<strong>Loctite</strong> ® Integrated<br />

Semi-Automatic<br />

Controllers with<br />

Low Level Sensors<br />

982720 / 982721 / 982723 /<br />

982724 / 982726 /<br />

982727 –<br />

<strong>Loctite</strong> ®<br />

Bond-A-Matic ®<br />

Reservoirs<br />

The RED represents the fluid path.<br />

1022006 –<br />

<strong>Loctite</strong> ® Digital<br />

Multi-Functional<br />

Controller<br />

97101 –<br />

<strong>Loctite</strong> ® Digital<br />

Dispense<br />

Controller<br />

97115 – <strong>Loctite</strong> ®<br />

Electric Rotorspray<br />

97118 / 97119 – <strong>Loctite</strong> ®<br />

Advancing Slides<br />

68<br />

For additional information and the full line of <strong>equipment</strong>, visit www.<strong>equipment</strong>.loctite.com.