OPERATOR'S MANUAL - The Baker Company Blog

OPERATOR'S MANUAL - The Baker Company Blog

OPERATOR'S MANUAL - The Baker Company Blog

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

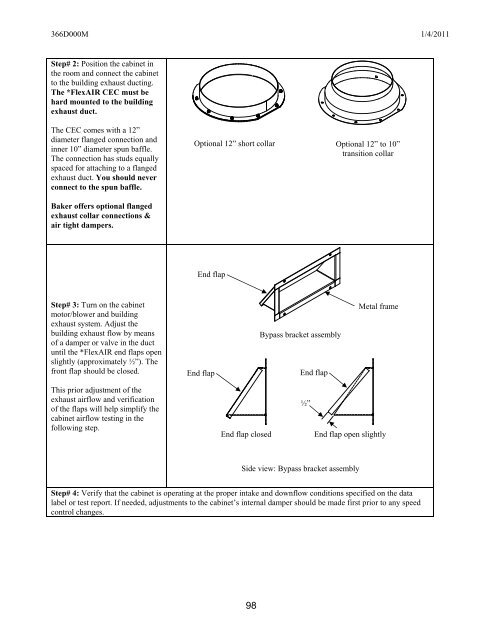

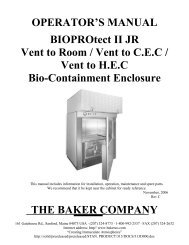

366D000M 1/4/2011Step# 2: Position the cabinet inthe room and connect the cabinetto the building exhaust ducting.<strong>The</strong> *FlexAIR CEC must behard mounted to the buildingexhaust duct.<strong>The</strong> CEC comes with a 12”diameter flanged connection andinner 10” diameter spun baffle.<strong>The</strong> connection has studs equallyspaced for attaching to a flangedexhaust duct. You should neverconnect to the spun baffle.<strong>Baker</strong> offers optional flangedexhaust collar connections &air tight dampers.Optional 12” short collarOptional 12” to 10”transition collarEnd flapStep# 3: Turn on the cabinetmotor/blower and buildingexhaust system. Adjust thebuilding exhaust flow by meansof a damper or valve in the ductuntil the *FlexAIR end flaps openslightly (approximately ½”). <strong>The</strong>front flap should be closed.End flapBypass bracket assemblyEnd flapMetal frameThis prior adjustment of theexhaust airflow and verificationof the flaps will help simplify thecabinet airflow testing in thefollowing step.End flap closed½”End flap open slightlySide view: Bypass bracket assemblyStep# 4: Verify that the cabinet is operating at the proper intake and downflow conditions specified on the datalabel or test report. If needed, adjustments to the cabinet’s internal damper should be made first prior to any speedcontrol changes.98