OPERATOR'S MANUAL - The Baker Company Blog

OPERATOR'S MANUAL - The Baker Company Blog

OPERATOR'S MANUAL - The Baker Company Blog

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

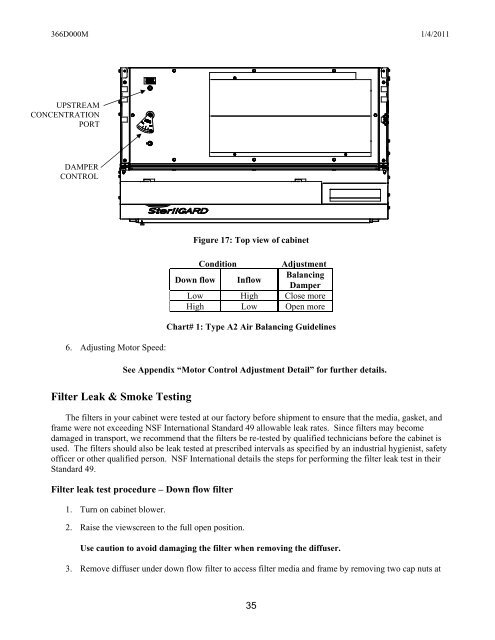

366D000M 1/4/2011UPSTREAMCONCENTRATIONPORTDAMPERCONTROL6. Adjusting Motor Speed:Figure 17: Top view of cabinetConditionAdjustmentDown flow InflowBalancingDamperLow High Close moreHigh Low Open moreChart# 1: Type A2 Air Balancing GuidelinesSee Appendix “Motor Control Adjustment Detail” for further details.Filter Leak & Smoke Testing<strong>The</strong> filters in your cabinet were tested at our factory before shipment to ensure that the media, gasket, andframe were not exceeding NSF International Standard 49 allowable leak rates. Since filters may becomedamaged in transport, we recommend that the filters be re-tested by qualified technicians before the cabinet isused. <strong>The</strong> filters should also be leak tested at prescribed intervals as specified by an industrial hygienist, safetyofficer or other qualified person. NSF International details the steps for performing the filter leak test in theirStandard 49.Filter leak test procedure – Down flow filter1. Turn on cabinet blower.2. Raise the viewscreen to the full open position.Use caution to avoid damaging the filter when removing the diffuser.3. Remove diffuser under down flow filter to access filter media and frame by removing two cap nuts at35