- Page 1 and 2:

THE BAKER COMPANYOPERATOR’S MANUA

- Page 3 and 4:

TABLE OF CONTENTSI - FUNCTION OF TH

- Page 5 and 6:

Stand Assembly Leg Extension Proced

- Page 7 and 8:

366D000M 1/4/2011Base Features• M

- Page 9 and 10:

366D000M 1/4/2011has 7/16” [11.1m

- Page 11 and 12:

366D000M 1/4/2011SpecificationsWeig

- Page 13 and 14:

366D000M 1/4/2011Environmental Cond

- Page 15 and 16:

366D000M 1/4/20111. Remove the stra

- Page 17 and 18:

366D000M 1/4/2011The *FlexAIR is an

- Page 19 and 20:

366D000M 1/4/2011Auxiliary Wiring O

- Page 21 and 22:

366D000M 1/4/2011Auxiliary Cabinet

- Page 23 and 24:

366D000M 1/4/2011• Ultraviolet (U

- Page 25 and 26:

366D000M 1/4/2011The Double Proximi

- Page 27 and 28:

366D000M 1/4/20113. Because opening

- Page 29 and 30:

366D000M 1/4/2011cabinets, since th

- Page 31 and 32:

366D000M 1/4/2011Recommended Decont

- Page 33 and 34:

366D000M 1/4/2011Method to seal an

- Page 35 and 36:

366D000M 1/4/20116. Tape sheeting t

- Page 37 and 38:

366D000M 1/4/2011and allow the two

- Page 39 and 40:

366D000M 1/4/2011IV - ONSITE CHECKS

- Page 41 and 42:

366D000M 1/4/2011the front, lowerin

- Page 43 and 44:

366D000M 1/4/2011A chemically conta

- Page 45 and 46:

366D000M 1/4/2011at a time until th

- Page 47 and 48:

366D000M 1/4/2011TroubleshootingIMP

- Page 49 and 50:

366D000M 1/4/2011V - DISASSEMBLY IN

- Page 51 and 52:

366D000M 1/4/2011Appendix46

- Page 53 and 54: 366D000M 1/4/2011Baker Part NumberM

- Page 55 and 56: 366D000M 1/4/2011SG403A-HE (With Ch

- Page 57 and 58: 366D000M 1/4/2011SG403A-HE (With Hy

- Page 59 and 60: 366D000M 1/4/2011SG503A-HE (Base Un

- Page 61 and 62: 366D000M 1/4/2011SG503A-HE (With Ch

- Page 63 and 64: 366D000M 1/4/2011SG503A-HE W/Canopy

- Page 65 and 66: 366D000M 1/4/2011SG603A-HE (With Ch

- Page 67 and 68: 366D000M 1/4/2011SG603A-HE (With Hy

- Page 69 and 70: 366D000M 1/4/2011SG403A-HE-INT (Wit

- Page 71 and 72: 366D000M 1/4/2011SG403A-HE-INT (Wit

- Page 73 and 74: 366D000M 1/4/2011SG603A-HE-INT (Wit

- Page 75 and 76: 366D000M 1/4/2011Cable Port Illustr

- Page 77 and 78: 366D000M 1/4/201172

- Page 79 and 80: 366D000M 1/4/201174

- Page 81 and 82: 366D000M 1/4/201176

- Page 83 and 84: 366D000M 1/4/2011FlexAIR Wiring78

- Page 85 and 86: 366D000M 1/4/2011Getting the cabine

- Page 87 and 88: 366D000M 1/4/20119) Bolt the leg in

- Page 89 and 90: 366D000M 1/4/2011Step 3: Place stan

- Page 91 and 92: 366D000M 1/4/2011Replacing Fluoresc

- Page 93 and 94: 366D000M 1/4/2011Installation of Ex

- Page 95 and 96: 366D000M 1/4/2011(This page intenti

- Page 97 and 98: 366D000M 1/4/2011Balancing Damper C

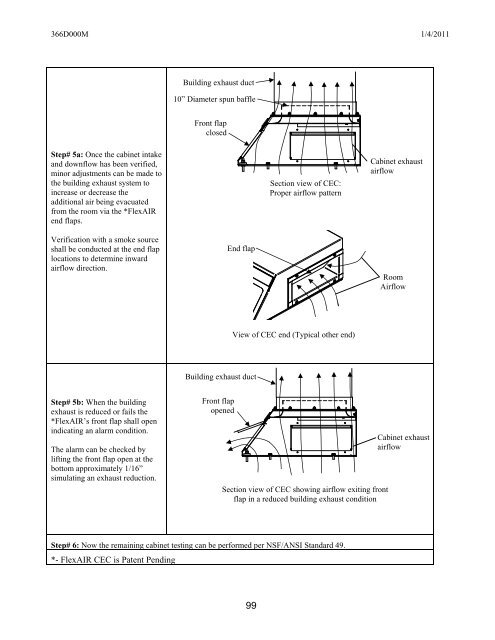

- Page 99 and 100: 366D000M 1/4/2011Installation Instr

- Page 101 and 102: 366D000M 1/4/2011TopBypass bracket

- Page 103: 366D000M 1/4/2011Step# 2: Position

- Page 107 and 108: 366D000M 1/4/201112) Adjust the tot

- Page 109 and 110: 366D000M 1/4/20115. Insert the 7”

- Page 111 and 112: 366D000M 1/4/2011Motor Control Adju

- Page 113 and 114: 366D000M 1/4/20114.) With the drive

- Page 115: 366D000M 1/4/2011WarrantyThe Baker