Inclination sensors

Inclination sensors

Inclination sensors

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

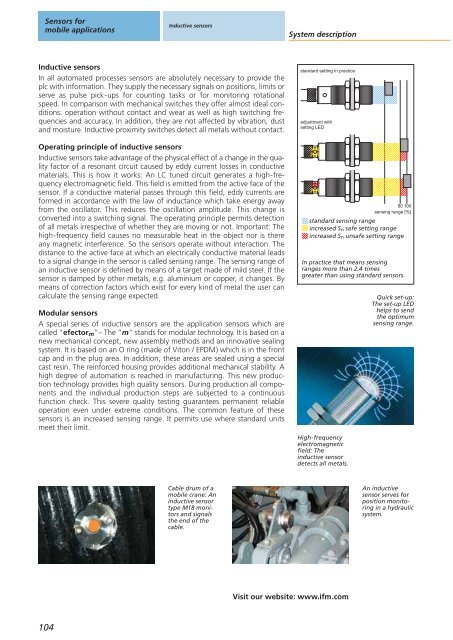

Sensors formobile applicationsInductive <strong>sensors</strong>System descriptionInductive <strong>sensors</strong>In all automated processes <strong>sensors</strong> are absolutely necessary to provide theplc with information. They supply the necessary signals on positions, limits orserve as pulse pick-ups for counting tasks or for monitoring rotationalspeed. In comparison with mechanical switches they offer almost ideal conditions:operation without contact and wear as well as high switching frequenciesand accuracy. In addition, they are not affected by vibration, dustand moisture. Inductive proximity switches detect all metals without contact.Operating principle of inductive <strong>sensors</strong>Inductive <strong>sensors</strong> take advantage of the physical effect of a change in the qualityfactor of a resonant circuit caused by eddy current losses in conductivematerials. This is how it works: An LC tuned circuit generates a high-frequencyelectromagnetic field. This field is emitted from the active face of thesensor. If a conductive material passes through this field, eddy currents areformed in accordance with the law of inductance which take energy awayfrom the oscillator. This reduces the oscillation amplitude. This change isconverted into a switching signal. The operating principle permits detectionof all metals irrespective of whether they are moving or not. Important: Thehigh-frequency field causes no measurable heat in the object nor is thereany magnetic interference. So the <strong>sensors</strong> operate without interaction. Thedistance to the active face at which an electrically conductive material leadsto a signal change in the sensor is called sensing range. The sensing range ofan inductive sensor is defined by means of a target made of mild steel. If thesensor is damped by other metals, e.g. aluminium or copper, it changes. Bymeans of correction factors which exist for every kind of metal the user cancalculate the sensing range expected.Modular <strong>sensors</strong>A special series of inductive <strong>sensors</strong> are the application <strong>sensors</strong> which arecalled “efector m ”– The “m” stands for modular technology. It is based on anew mechanical concept, new assembly methods and an innovative sealingsystem. It is based on an O ring (made of Viton / EPDM) which is in the frontcap and in the plug area. In addition, these areas are sealed using a specialcast resin. The reinforced housing provides additional mechanical stability. Ahigh degree of automation is reached in manufacturing. This new productiontechnology provides high quality <strong>sensors</strong>. During production all componentsand the individual production steps are subjected to a continuousfunction check. This severe quality testing guarantees permanent reliableoperation even under extreme conditions. The common feature of these<strong>sensors</strong> is an increased sensing range. It permits use where standard unitsmeet their limit.standard setting in practiceadjustment withsetting LEDHigh-frequencyelectromagneticfield: Theinductive sensordetects all metals.80 100sensing range [%]standard sensing rangeincreased S n safe setting rangeincreased S n unsafe setting rangeIn practice that means sensingranges more than 2.4 timesgreater than using standard <strong>sensors</strong>.Quick set-up:The set-up LEDhelps to sendthe optimumsensing range.Cable drum of amobile crane: Aninductive sensortype M18 monitorsand signalsthe end of thecable.An inductivesensor serves forposition monitoringin a hydraulicsystem.Visit our website: www.ifm.com104