Development of Karl Fischer Reagents

Development of Karl Fischer Reagents

Development of Karl Fischer Reagents

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

I-1. Questions & Answers about <strong>Karl</strong> <strong>Fischer</strong> <strong>Reagents</strong><br />

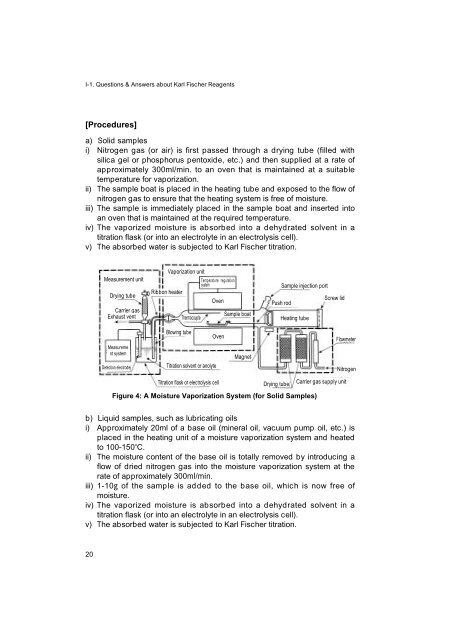

[Procedures]<br />

a) Solid samples<br />

i) Nitrogen gas (or air) is first passed through a drying tube (filled with<br />

silica gel or phosphorus pentoxide, etc.) and then supplied at a rate <strong>of</strong><br />

approximately 300ml/min. to an oven that is maintained at a suitable<br />

temperature for vaporization.<br />

ii) The sample boat is placed in the heating tube and exposed to the flow <strong>of</strong><br />

nitrogen gas to ensure that the heating system is free <strong>of</strong> moisture.<br />

iii) The sample is immediately placed in the sample boat and inserted into<br />

an oven that is maintained at the required temperature.<br />

iv) The vaporized moisture is absorbed into a dehydrated solvent in a<br />

titration flask (or into an electrolyte in an electrolysis cell).<br />

v) The absorbed water is subjected to <strong>Karl</strong> <strong>Fischer</strong> titration.<br />

b) Liquid samples, such as lubricating oils<br />

i) Approximately 20ml <strong>of</strong> a base oil (mineral oil, vacuum pump oil, etc.) is<br />

placed in the heating unit <strong>of</strong> a moisture vaporization system and heated<br />

to 100-150 � C.<br />

ii) The moisture content <strong>of</strong> the base oil is totally removed by introducing a<br />

flow <strong>of</strong> dried nitrogen gas into the moisture vaporization system at the<br />

rate <strong>of</strong> approximately 300ml/min.<br />

iii) 1-10g <strong>of</strong> the sample is added to the base oil, which is now free <strong>of</strong><br />

moisture.<br />

iv) The vaporized moisture is absorbed into a dehydrated solvent in a<br />

titration flask (or into an electrolyte in an electrolysis cell).<br />

v) The absorbed water is subjected to <strong>Karl</strong> <strong>Fischer</strong> titration.<br />

20<br />

Measurement unit<br />

Drying tube<br />

Carrier gas<br />

Exhaust vent<br />

Measureme<br />

nt system<br />

Detection electrode<br />

Vaporization unit<br />

Temperature regulation<br />

system<br />

Ribbon heater<br />

Oven<br />

Thermocouple<br />

Blowing tube<br />

Titration solvent or anolyte<br />

Oven<br />

Sample boat<br />

Magnet<br />

Sample injection port<br />

Push rod<br />

Heating tube<br />

Screw lid<br />

Titration flask or electrolysis cell<br />

Drying tube<br />

Carrier gas supply unit<br />

Figure 4: A Moisture Vaporization System (for Solid Samples)<br />

Flowmeter<br />

Nitrogen