- Page 2 and 3:

HORTICULTURE Principles and Practic

- Page 4 and 5:

HORTICULTURE Principles and Practic

- Page 6 and 7:

With love to Theresa, quarterback;

- Page 8 and 9:

Brief Contents Preface xxi PART 1 T

- Page 10 and 11:

Contents Preface xxi PART 1 THE UND

- Page 12 and 13:

5.3 PLANT GROWTH PROCESSES 160 5.4

- Page 14 and 15:

8.20 COMMON GREENHOUSE DISEASES 276

- Page 16 and 17:

12.3 INTERNAL ENVIRONMENTAL CONTROL

- Page 18 and 19:

PART 6 Summary 541 References and S

- Page 20 and 21:

22.18 INDOOR COMPOSTING SYSTEMS 668

- Page 22 and 23:

Preface Horticulture is the area of

- Page 24 and 25:

ACKNOWLEDGMENTS I am very grateful

- Page 26 and 27:

PART 1 THE UNDERLYING SCIENCE CHAPT

- Page 28 and 29:

1 What Is Horticulture? PURPOSE AND

- Page 30 and 31:

(a) (c) (b) (d) FIGURE 1-1 The many

- Page 32 and 33:

FIGURE 1 Bridge. The plaza view of

- Page 34 and 35:

CYCADS Many people mistake these pr

- Page 36 and 37:

FIGURE 2 The world's largest unbran

- Page 38 and 39:

FIGURE 2 Sold flowers are loaded on

- Page 40 and 41:

FIGURE 1-4 Formal landscaping featu

- Page 42 and 43:

1.4 ROLEOFTHENURSERY AND SEED INDUS

- Page 44 and 45:

1.5 HORTICULTURE AND SOCIETY Hortic

- Page 46 and 47:

TABLE 1-3 U.S. Horticultural Export

- Page 48 and 49:

Turfgrass Operation 1. Landscape te

- Page 50 and 51:

What Is Horticulture? This site pro

- Page 52 and 53:

Examples of botanical gardens http:

- Page 54 and 55:

2 Classifying and Naming Horticultu

- Page 56 and 57:

Eight major taxa are commonly used

- Page 58 and 59:

TABLE 2-3 The Divisions of the King

- Page 60 and 61:

HISTORY OF PLANT TAXONOMY PAUL R. F

- Page 62 and 63:

AGE OF HERBALISTS Two major events

- Page 64 and 65:

possible system of nomenclature. Ho

- Page 66 and 67:

TABLE 1 Type Categories for Plant N

- Page 68 and 69:

2.3 OTHER CLASSIFICATION SYSTEMS (O

- Page 70 and 71:

2. Shrubs. A shrub has no main trun

- Page 72 and 73:

Simple Fruits Fleshy Fruits Drupe B

- Page 74 and 75:

FIGURE 2-14 A pome, represented by

- Page 76 and 77:

2.3.5 CLASSIFICATION OF VEGETABLES

- Page 78 and 79:

(a) (b) FIGURE 2-22 (Source: George

- Page 80 and 81:

FIGURE 2-25 A narrowleaf plant. (So

- Page 82 and 83:

FIGURE 2-29 Parts of a typical gras

- Page 84 and 85:

such as rosemary, sage, thyme, marj

- Page 86 and 87:

c. Leaves d. Bulbs 2. Cut across (t

- Page 88 and 89:

Whole plant Organs FIGURE 3-1 Level

- Page 90 and 91:

ibonucleic acid (RNA), proteins, an

- Page 92 and 93:

called cristae; this extreme foldin

- Page 94 and 95:

By virtue of its position, the prim

- Page 96 and 97:

Phloem Tissue Structurally, phloem

- Page 98 and 99:

(a) Stalk (b) Culm FIGURE 3-5 Cross

- Page 100 and 101:

Scale Compressed stem (a) Whole bul

- Page 102 and 103:

Upper epidermis Palisade layer FIGU

- Page 104 and 105:

usually occur in xerophytes. In cer

- Page 106 and 107:

FIGURE 3-22 Selected common leaf ma

- Page 108 and 109:

FIGURE 3-25 Selected common leaf ti

- Page 110 and 111:

absorption of water and minerals fr

- Page 112 and 113:

Outer bark Inner bark FIGURE 3-37 T

- Page 114 and 115:

Anther Filament Stamen FIGURE 3-41

- Page 116 and 117:

Exocarp Parts of a typi- FIGURE 3-4

- Page 118 and 119:

PRACTICAL EXPERIENCE LABORATORY 1.

- Page 120 and 121:

4.1 CLIMATE, WEATHER, AND HORTICULT

- Page 122 and 123:

concentration in the atmosphere.A c

- Page 124 and 125:

TABLE 4-1 Climatic Adaptation of Se

- Page 126 and 127:

and upward. Another important gener

- Page 128 and 129:

Rate of photosynthesis mg/sq. dm/hr

- Page 130 and 131:

and plants that flower under only c

- Page 132 and 133:

times of the year. Growers start th

- Page 134 and 135:

content. This section is sometimes

- Page 136 and 137:

TABLE 4-7 Soil Mineral Nutrients Es

- Page 138 and 139:

Micronutrients (Trace Elements) Mic

- Page 140 and 141:

Neutral FIGURE 4-11 A representatio

- Page 142 and 143:

4.4 FERTILIZERS Fertilizer sources

- Page 144 and 145:

One of the most commonly used contr

- Page 146 and 147:

Chlorosis (the yellowing of green l

- Page 148 and 149:

Fertilizers may be applied before p

- Page 150 and 151:

It is neither practical nor safe to

- Page 152 and 153:

Solution: How much of ammonium nitr

- Page 154 and 155:

1°C (34°F), the optimum temperatu

- Page 156 and 157:

Cellulose sponge Perched water tabl

- Page 158 and 159:

Overhead Sprinkler Irrigation Water

- Page 160 and 161:

FIGURE 4-19 Furrow irrigation of le

- Page 162 and 163:

can self-install an underground irr

- Page 164 and 165:

1. Surface drainage. Surface draina

- Page 166 and 167:

Secondary Tillage Primary tillage i

- Page 168 and 169:

(a) (b) (c) (d) FIGURE 4-20 (Source

- Page 170 and 171:

texture. The most commonly used gra

- Page 172 and 173:

TABLE 4-11 Selected Standard Mixes

- Page 174 and 175:

Steam Pasteurization Steam pasteuri

- Page 176 and 177:

Maracher, H. 1986. Mineral nutritio

- Page 178 and 179:

5 Plant Physiology PURPOSE AND EXPE

- Page 180 and 181:

Growth in an organism follows a cer

- Page 182 and 183:

5.1.2 THE ROLE OF SIGNALS IN GROWTH

- Page 184 and 185:

waxes are embedded. Waxes consist o

- Page 186 and 187:

5.3.1 PHOTOSYNTHESIS Photosynthesis

- Page 188 and 189:

CO 2 FIGURE 5-6 The C 4 pathway of

- Page 190 and 191:

Growth and Development The general

- Page 192 and 193:

TABLE 5-2 Energy Produced from Aero

- Page 194 and 195:

Certain plants are adapted to dry e

- Page 196 and 197:

conditions exist to sustain growth

- Page 198 and 199:

Shoot Elongation In certain plants,

- Page 200 and 201:

for success, since high temperature

- Page 202 and 203:

FIGURE 5-13 Ripening of plantain sh

- Page 204 and 205:

Terminal bud removed Unbranched pla

- Page 206 and 207:

conditions—pertaining to light, m

- Page 208 and 209:

them to maturity. The major process

- Page 210 and 211:

6 Breeding Horticultural Plants PUR

- Page 212 and 213:

Similarly, there can be no plant br

- Page 214 and 215:

APPLICATION, CHALLENGES, AND PROSPE

- Page 216 and 217:

hit with target DNA. Therefore, it

- Page 218 and 219:

Generally, within ten days of exper

- Page 220 and 221:

Aziz A.N., Sauve R.J., Zhou S., 200

- Page 222 and 223:

(b) F 1 Rr Rr round round F 2 RR R

- Page 224 and 225:

e.g., Aa × Aa), the lethal allele

- Page 226 and 227:

eeder’s equation. Simply stated,

- Page 228 and 229:

Before the seed or product becomes

- Page 230 and 231:

6.18.2 THE GENERAL STEPS OF RDNA TE

- Page 232 and 233:

2. Political disagreement. There ar

- Page 234 and 235:

REFERENCES AND SUGGESTED READING Ac

- Page 236 and 237:

PART 2 PROTECTING HORTICULTURAL PLA

- Page 238 and 239:

7 Biological Enemies of Horticultur

- Page 240 and 241:

8. Weeds may clog drains, waterways

- Page 242 and 243:

is also a root parasite that obtain

- Page 244 and 245:

LEGISLATIVE Both state and federal

- Page 246 and 247:

Example Integrated cultural, physic

- Page 248 and 249:

7.4.2 IMPORTANT INSECT ORDERS Insec

- Page 250 and 251:

Egg FIGURE 7-3 Life cycle of an ins

- Page 252 and 253:

sucking insects (also found with so

- Page 254 and 255:

FIGURE 7-12 Corn earworm damage. (S

- Page 256 and 257:

TABLE 7-1 Selected Fungal Diseases

- Page 258 and 259:

7.6.1 SMALL ANIMALS Rabbits, mice,

- Page 260 and 261:

FIGURE 7-16 The disease triangle. P

- Page 262 and 263:

fungitoxic exudates in its leaves,

- Page 264 and 265:

SUMMARY Insects are a major class o

- Page 266 and 267:

For the home growers or those who c

- Page 268 and 269:

for consumers and the environment).

- Page 270 and 271:

TABLE 8-1 Strategy 4: Strategies an

- Page 272 and 273:

gibberellic acid spray overcomes st

- Page 274 and 275:

In a competitive industry, a variet

- Page 276 and 277:

Chemicals gain access to humans thr

- Page 278 and 279:

2. Pesticide management. Controllin

- Page 280 and 281:

Every organism has its natural enem

- Page 282 and 283:

TABLE 8-3 Selected Examples of Biol

- Page 284 and 285:

1 2 YEAR 3 4 FIGURE 8-5 cycle. A cr

- Page 286 and 287:

6. Heat treatment. In the greenhous

- Page 288 and 289:

Organic Compounds (Organics) Organi

- Page 290 and 291:

under enclosed conditions (e.g., wa

- Page 292 and 293:

FIGURE 8-9 A tractor-mounted spraye

- Page 294 and 295:

8.11.9 LANDSCAPE PESTS AND THEIR CO

- Page 296 and 297:

application, a particular herbicide

- Page 298 and 299:

Further, they do not provide unifor

- Page 300 and 301:

SUMMARY Herbicides are chemicals us

- Page 302 and 303:

Sulfur may be applied for both prev

- Page 304 and 305:

8.23 PREVENTING GREENHOUSE DISEASES

- Page 306 and 307:

PART 3 PROPAGATING HORTICULTURAL PL

- Page 308 and 309:

9 Sexual Propagation PURPOSE AND EX

- Page 310 and 311:

Anther Microspore Megaspore mother

- Page 312 and 313:

Lettuce seeds Red light Darkness Fa

- Page 314 and 315:

FEDERAL AND STATE SEED LAWS Federal

- Page 316 and 317:

Germination Test In laboratory prac

- Page 318 and 319:

FIGURE 15 The essential structures

- Page 320 and 321:

processing into flour or meal). How

- Page 322 and 323:

physiologically immature seeds must

- Page 324 and 325:

seeds may be treated in this way be

- Page 326 and 327:

The two basic modes of seedling eme

- Page 328 and 329:

locations in the field. Home garden

- Page 330 and 331:

FIGURE 9-9 A plastic flat. (Source:

- Page 332 and 333:

(a) (b) FIGURE 9-12 (a) Sowing seed

- Page 334 and 335:

y the gardener or grower. Whatever

- Page 336 and 337:

REFERENCES AND SUGGESTED READING Co

- Page 338 and 339:

species enables vegetative propagat

- Page 340 and 341:

for rapid rooting. There are two ba

- Page 342 and 343:

Cutting involving one node (e.g., s

- Page 344 and 345:

This practice is especially importa

- Page 346 and 347:

10.6.4 STICKING THE CUTTING Cutting

- Page 348 and 349:

(a) Indexing by budding Diseased pl

- Page 350 and 351:

10.11 M ETHODS OF GRAFTING Grafting

- Page 352 and 353:

Scion Wax FIGURE 10-17 Steps in bar

- Page 354 and 355:

MODULE 3 BUDDING 10.12 TYPES OF BUD

- Page 356 and 357:

MODULE 4 LAYERING 10.13 TYPES OF LA

- Page 358 and 359:

Buried part of shoot is nicked FIGU

- Page 360 and 361:

variety of ways. In air layering, a

- Page 362 and 363:

FIGURE 10-34 by using cormels. Prop

- Page 364 and 365:

Psuedobulbs In the Dendrobium orchi

- Page 366 and 367:

The technique is used widely in cro

- Page 368 and 369:

PART 4 GROWING PLANTS INDOORS CHAPT

- Page 370 and 371:

11 Growing Houseplants PURPOSE AND

- Page 372 and 373:

TABLE 11-1 Common houseplants Commo

- Page 374 and 375:

Saddle leaf Philodendron selloum To

- Page 376 and 377:

Window Displays Plants in windows e

- Page 378 and 379:

CONTAINER GARDENS DR. TERRI W. STAR

- Page 380 and 381:

annuals and hardy perennial species

- Page 382 and 383:

of the large container filled with

- Page 384 and 385:

perfection about four to six weeks

- Page 386 and 387:

FIGURE 11-6 Flowers displayed on th

- Page 388 and 389:

TABLE 11-5 Plant Selected Plants fo

- Page 390 and 391:

The lighting condition near these w

- Page 392 and 393:

Fluorescent Lights Fluorescent ligh

- Page 394 and 395:

may be used for one pot or a group

- Page 396 and 397:

garden rooms, atriums, or a large c

- Page 398 and 399:

The photoperiod affects when the ho

- Page 400 and 401:

patted firm to keep the plant erect

- Page 402 and 403:

Other Materials Apart from clay and

- Page 404 and 405:

(a) ( FIGURE 11-25 Support for plan

- Page 406 and 407:

TABLE 11-7 Common Problems of House

- Page 408 and 409:

• Keep soil moist all the time

- Page 410 and 411:

• Prefers high temperatures • P

- Page 412 and 413:

amount and quality of light. If sup

- Page 414 and 415:

12 Controlled-Environment Horticult

- Page 416 and 417:

6. Curvilinear 7. Curved eave 8. Do

- Page 418 and 419:

Detached greenhouses have several a

- Page 420 and 421:

12.2.3 FRAME DESIGN There are two b

- Page 422 and 423:

horticultural business a less-expen

- Page 424 and 425:

Texas, Hawaii, and California. The

- Page 426 and 427:

source of heat for times when the t

- Page 428 and 429:

FIGURE 12-17 Greenhouse production

- Page 430 and 431:

FIGURE 12-21 Moving tables allowing

- Page 432 and 433:

Research program on greenhouse engi

- Page 434 and 435:

greenhouses equipped with a variety

- Page 436 and 437:

FIGURE 1 Annual energy required per

- Page 438 and 439:

This system was demonstrated in a 5

- Page 440 and 441:

FIGURE 6 Amounts of waste energy ut

- Page 442 and 443:

Ekholt, B.A., D.R. Mears, M.S. Gini

- Page 444 and 445:

or object to be warmed. Failure to

- Page 446 and 447:

objects in its path (e.g., the floo

- Page 448 and 449:

FIGURE 12-27 Motorized ventilation

- Page 450 and 451:

FIGURE 12-30 Movable internal shade

- Page 452 and 453:

FIGURE 12-33 A high pressure sodium

- Page 454 and 455:

Source of Water The quality of loca

- Page 456 and 457:

FIGURE 12-37 Overhead sprinkler irr

- Page 458 and 459:

Intermittent Feed Greenhouse plants

- Page 460 and 461:

However, in winter, greenhouse vent

- Page 462 and 463:

OUTCOMES ASSESSMENT 1. Explain the

- Page 464 and 465:

. Foliage or green plants. Foliage

- Page 466 and 467:

2. Labor. The size of the labor for

- Page 468 and 469:

FIGURE 13-1 Greenhouse production o

- Page 470 and 471:

FIGURE 13-2 Lettuce plug is inserte

- Page 472 and 473:

13.8.4 AGGREGATE HYDROPONIC SYSTEMS

- Page 474 and 475:

(a) (b) (c) FIGURE 13-6 Plug produc

- Page 476 and 477:

14 Growing Succulents PURPOSE AND E

- Page 478 and 479:

FIGURE 14-3 Leaf succulent represen

- Page 480 and 481:

frost-hardy. Their rosettes are usu

- Page 482 and 483:

TABLE 14-1 Plant Selected Popular S

- Page 484 and 485:

(a) (b) FIGURE 14-12 Typical bromel

- Page 486 and 487:

14.7.1 WHAT ARE CACTI? 14.7 CACTI C

- Page 488 and 489:

FIGURE 14-16 Opuntia. (Source: Crai

- Page 490 and 491:

FIGURE 14-23 Mammillaria. (Source:

- Page 492 and 493:

FIGURE 14-28 Both desert and jungle

- Page 494 and 495:

Growing mix Gravel Cacti (a) (b) FI

- Page 496 and 497:

PART5 GROWING PLANTS OUTDOORS: ORNA

- Page 498 and 499:

15 Principles of Landscaping PURPOS

- Page 500 and 501:

8. Create recreational grounds. Suc

- Page 502 and 503:

knowledge, with concern for resourc

- Page 504 and 505:

(a) (b) (c) FIGURE 15-2 The occurre

- Page 506 and 507:

GUIDELINES FOR LANDSCAPE DESIGN DAV

- Page 508 and 509:

the landscape. Some very successful

- Page 510 and 511:

Rhythm and Line Panoramic view of a

- Page 512 and 513:

FIGURE 15-10 A formal garden. The e

- Page 514 and 515:

How frequently do they entertain? A

- Page 516 and 517:

the patio should be located on the

- Page 518 and 519:

15.7.1 SELECTING PLANTS A homeowner

- Page 520 and 521:

Plant Arrangement in the Landscape

- Page 522 and 523:

Shadow FIGURE 15-15 Planting a tree

- Page 524 and 525:

SUMMARY Landscaping enhances the su

- Page 526 and 527:

3. Supply materials on a timely bas

- Page 528 and 529:

such as preparation rooms (for mixi

- Page 530 and 531:

of environmental fluctuations. Furt

- Page 532 and 533:

FIGURE 16-4 A bare-root tree seedli

- Page 534 and 535:

17 Installation of the Landscape PU

- Page 536 and 537:

for walks, driveways, and patios (F

- Page 538 and 539:

Planting may be limited to accentin

- Page 540 and 541:

17.3.3 PREPARING THE BED The soil s

- Page 542 and 543:

FIGURE 17-4 Bedding plants raised i

- Page 544 and 545:

SUMMARY Bedding plants are largely

- Page 546 and 547:

TABLE 17-6 Selected Ground Covers T

- Page 548 and 549:

TABLE 17-7 Selected Ornamental Gras

- Page 550 and 551:

they determine the success and surv

- Page 552 and 553:

12. Wildlife attraction. Trees in t

- Page 554 and 555:

pennsylvanica), hackberry (Celtis s

- Page 556 and 557:

y winds. A stake, which is often a

- Page 558 and 559:

TABLE 17-8 Selected Narrowleaf Ever

- Page 560 and 561:

TABLE 17-11 Selected Deciduous Shru

- Page 562 and 563:

Blooming bushes 1. Blue mist shrub

- Page 564 and 565:

Planting Bulblets and Bulbils Speci

- Page 566 and 567:

may be divided such that each secti

- Page 568 and 569:

FIGURE 18-1 (Source: George Acquaah

- Page 570 and 571:

Cool-Season (Temperate) Grasses In

- Page 572 and 573:

Growth Habit Turfgrasses are the mo

- Page 574 and 575:

Heavy Use Lawns on playgrounds and

- Page 576 and 577:

The seed should be free from weeds

- Page 578 and 579:

Source of Sod As with seed, sod sup

- Page 580 and 581:

A plug of sod FIGURE 18-7 Plugging

- Page 582 and 583:

way, plants are able to adapt to th

- Page 584 and 585:

form of a can placed on the lawn wi

- Page 586 and 587:

TABLE 18-3 Some Common Lawn and Tur

- Page 588 and 589:

even surface soil surface for layin

- Page 590 and 591: MacCaskey, M. 1987. All about lawns

- Page 592 and 593: Pruning is sometimes done in conjun

- Page 594 and 595: 4. Pruning may be done to reduce th

- Page 596 and 597: 19.4.2 SAWS A saw may be designed t

- Page 598 and 599: defeat the purpose of pruning. The

- Page 600 and 601: Bud withers as cut end dries back d

- Page 602 and 603: 19.6 STRATEGIES FOR PRUNING ABOVEGR

- Page 604 and 605: Rejuvenation Pruning Cut canes to a

- Page 606 and 607: 3. In the third and subsequent year

- Page 608 and 609: (a) Cut Prune (b) FIGURE 19-16 Step

- Page 610 and 611: Eucalyptus and Paulownia are amenab

- Page 612 and 613: TRAINING & PRUNING DECIDUOUS FRUIT

- Page 614 and 615: Summer pruning eliminates an energy

- Page 616 and 617: a) b) FIGURE 2 Newly planted apple

- Page 618 and 619: FIGURE 6 Wooden limb spreaders can

- Page 620 and 621: FIGURE 9. An apple tree trained to

- Page 622 and 623: years to promote continued lateral

- Page 624 and 625: Horizontal Espalier The horizontal

- Page 626 and 627: 19.16.1 CANE FRUITS Cane fruits are

- Page 628 and 629: FIGURE 19-26 Shearing of Christmas

- Page 630 and 631: pyramid-like form that is wider at

- Page 632 and 633: After selecting the appropriate spe

- Page 634 and 635: PART 6 GROWING PLANTS OUTDOORS: VEG

- Page 636 and 637: 20 Growing Vegetables Outdoors PURP

- Page 638 and 639: The National Agricultural Statistic

- Page 642 and 643: growers should take to determine an

- Page 644 and 645: pests and reduce/ eliminate hail da

- Page 646 and 647: square yard (10 to 68 grams per squ

- Page 648 and 649: High tunnels help increase the prof

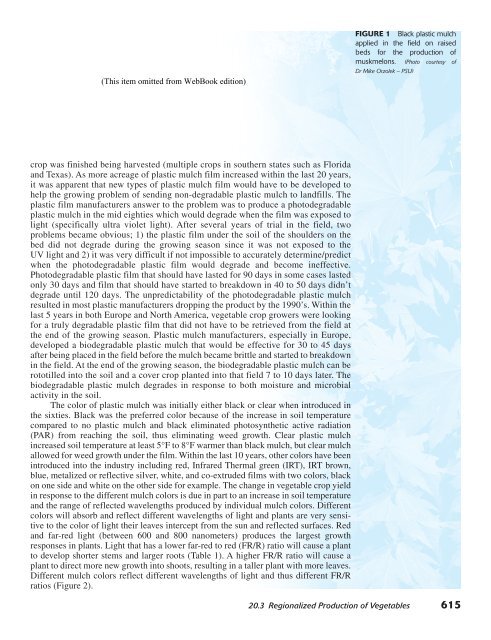

- Page 650 and 651: (This item omitted from WebBook edi

- Page 652 and 653: 20.4 VEGETABLE MARKET TYPES Fresh V

- Page 654 and 655: Establishing the Crop Planting into

- Page 656 and 657: home water supply from the tap. Thi

- Page 658 and 659: Cole crop Cabbage Root Potato Bean

- Page 660 and 661: 6. Adequate nutrition. While overfe

- Page 662 and 663: variable, ranging from creamy yello

- Page 664 and 665: There are two general production pr

- Page 666 and 667: This toxin is heat resistant and no

- Page 668 and 669: large, or jumbo. The bulb may be sw

- Page 670 and 671: REFERENCES Growing selected vegetab

- Page 672 and 673: TABLE 21-1 Popular Herbs and Their

- Page 674 and 675: (a) (b) (c) (d) (e) (f) FIGURE 21-1

- Page 676 and 677: 22 Organic Farming PURPOSE AND EXPE

- Page 678 and 679: 22.3 PRINCIPLES OF ORGANIC FARMING

- Page 680 and 681: and the specific materials to be us

- Page 682 and 683: 22.8 MANAGING SOIL PHYSICAL QUALITY

- Page 684 and 685: preemergent or early postemergent o

- Page 686 and 687: Composting is a deliberate activity

- Page 688 and 689: 22.14.5 THE CARBON-TO-NITROGEN RATI

- Page 690 and 691:

Moisture Supply Water is required b

- Page 692 and 693:

Compost materials FIGURE 22-4 a wir

- Page 694 and 695:

As microbial decomposition proceeds

- Page 696 and 697:

Establishment and Management of an

- Page 698 and 699:

night, freezing can occur in spring

- Page 700 and 701:

accomplished by stratification. It

- Page 702 and 703:

transmitted by the dagger nematode

- Page 704 and 705:

PART 7 SPECIAL TECHNIQUES AND HANDL

- Page 706 and 707:

24 Cut Flowers and Floral Design PU

- Page 708 and 709:

to more than four-fold in standard

- Page 710 and 711:

Temperature and Humidity Wilting re

- Page 712 and 713:

FLORAL DESIGN: AN OVERVIEW BY WM. J

- Page 714 and 715:

Principle Definition Types (or Uses

- Page 716 and 717:

pH value-a measure of the acidity o

- Page 718 and 719:

FIGURE 6 Parallel Design-Parallel d

- Page 720 and 721:

24.3.2 TOOLS AND MATERIALS The tool

- Page 722 and 723:

3. Establish the focal point. 4. Ad

- Page 724 and 725:

Natural Drying To dry naturally, fl

- Page 726 and 727:

24.4.3 DRIED FLOWER ARRANGEMENTS Dr

- Page 728 and 729:

25 Terrarium Culture PURPOSE AND EX

- Page 730 and 731:

FIGURE 25-3 Terrarium containers ar

- Page 732 and 733:

FIGURE 25-5 Assortment of tools use

- Page 734 and 735:

25.6.7 ENHANCING THE DISPLAY Certai

- Page 736 and 737:

(a) (b) FIGURE 26-1 Bonsai can be c

- Page 738 and 739:

TABLE 26-3 Plant A Selection of Pop

- Page 740 and 741:

26.3.1 COLLECTING BONSAI PLANTS FRO

- Page 742 and 743:

Strip bark Bare branch FIGURE 26-9

- Page 744 and 745:

26.5.2 SANITATION It is critical to

- Page 746 and 747:

27 Postharvest Handling and Marketi

- Page 748 and 749:

whereas oranges are picked (they ha

- Page 750 and 751:

(b) (a) (c) (d) (e1) (e2) (f) FIGUR

- Page 752 and 753:

To reduce packaging injury, contain

- Page 754 and 755:

is replaced by the by-product of re

- Page 756 and 757:

Stored produce may lose some color,

- Page 758 and 759:

with pricing. When selling by volum

- Page 760 and 761:

(a) (b) FIGURE 27-5 Horticultural p

- Page 762 and 763:

APPENDIX A Temperature: Converting

- Page 764 and 765:

APPENDIX B Metric Conversion Chart

- Page 766 and 767:

APPENDIX D Common and Scientific Na

- Page 768 and 769:

Pecan (Carya illinoensis) Peony (Pa

- Page 770 and 771:

GLOSSARY A Abaxial Turned away from

- Page 772 and 773:

Cellulose A complex carbohydrate th

- Page 774 and 775:

Floriculture The science and practi

- Page 776 and 777:

M Macronutrient An essential elemen

- Page 778 and 779:

Root cap A mass of hard cells cover

- Page 780 and 781:

INDEX A-frame, 395 A-horizon, 108 A

- Page 782 and 783:

defined, 390 fertilization, 432-434

- Page 784 and 785:

Radiant heaters, 378 Radicle, 90 Re

- Page 786 and 787:

color plate 1 (a) (b) (c) (d) (e) M

- Page 788 and 789:

color plate 3 (b) (a) (c) (d) (e) (

- Page 790 and 791:

color plate 5 (a) (b) (d) (c) (e) (

- Page 792 and 793:

color plate 7 (b) (c) (d) (a) (e) (

- Page 794 and 795:

color plate 9 (a) (b) (c) (d) (e) (

- Page 796 and 797:

color plate 11 (a) (c) (b) (d) Grow

- Page 798 and 799:

color plate 13 (a) (b) (c) (d) (e)

- Page 800 and 801:

color plate 15 (a) (b) (c) (d) (e)

- Page 802 and 803:

color plate 17 (a) (b) (c) (d) (e)

- Page 804 and 805:

color plate 19 (a) (b) (c) (d) (e)

- Page 806 and 807:

color plate 21 (a) (b) (c) (e) (d)

- Page 808 and 809:

color plate 23 (c) (b) (a) (d) (e)

- Page 810 and 811:

color plate 25 (c) (a) (b) (d) (e)

- Page 812 and 813:

color plate 27 (a1) (a2) (b2) (b1)

- Page 814 and 815:

color plate 29 (a) (b) (c) (d) (e)

- Page 816 and 817:

color plate 31 (a) (b) (c) Floral d