mag

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Malaysia Water Research Journal<br />

Test<br />

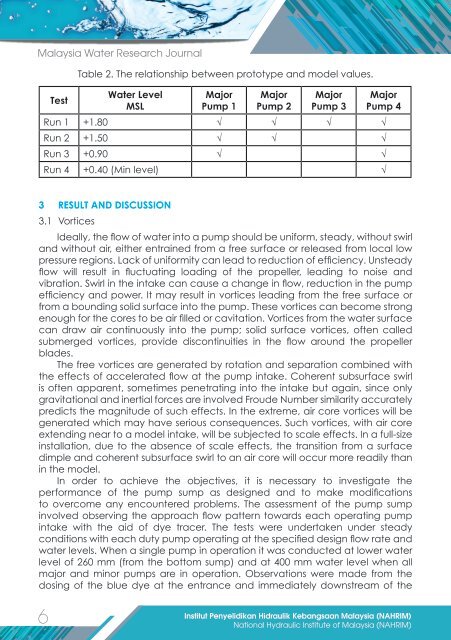

Table 2. The relationship between prototype and model values.<br />

Water Level<br />

MSL<br />

Major<br />

Pump 1<br />

Major<br />

Pump 2<br />

Major<br />

Pump 3<br />

Major<br />

Pump 4<br />

Run 1 +1.80 √ √ √ √<br />

Run 2 +1.50 √ √ √<br />

Run 3 +0.90 √ √<br />

Run 4 +0.40 (Min level) √<br />

3 RESULT AND DISCUSSION<br />

3.1 Vortices<br />

Ideally, the flow of water into a pump should be uniform, steady, without swirl<br />

and without air, either entrained from a free surface or released from local low<br />

pressure regions. Lack of uniformity can lead to reduction of efficiency. Unsteady<br />

flow will result in fluctuating loading of the propeller, leading to noise and<br />

vibration. Swirl in the intake can cause a change in flow, reduction in the pump<br />

efficiency and power. It may result in vortices leading from the free surface or<br />

from a bounding solid surface into the pump. These vortices can become strong<br />

enough for the cores to be air filled or cavitation. Vortices from the water surface<br />

can draw air continuously into the pump; solid surface vortices, often called<br />

submerged vortices, provide discontinuities in the flow around the propeller<br />

blades.<br />

The free vortices are generated by rotation and separation combined with<br />

the effects of accelerated flow at the pump intake. Coherent subsurface swirl<br />

is often apparent, sometimes penetrating into the intake but again, since only<br />

gravitational and inertial forces are involved Froude Number similarity accurately<br />

predicts the <strong>mag</strong>nitude of such effects. In the extreme, air core vortices will be<br />

generated which may have serious consequences. Such vortices, with air core<br />

extending near to a model intake, will be subjected to scale effects. In a full-size<br />

installation, due to the absence of scale effects, the transition from a surface<br />

dimple and coherent subsurface swirl to an air core will occur more readily than<br />

in the model.<br />

In order to achieve the objectives, it is necessary to investigate the<br />

performance of the pump sump as designed and to make modifications<br />

to overcome any encountered problems. The assessment of the pump sump<br />

involved observing the approach flow pattern towards each operating pump<br />

intake with the aid of dye tracer. The tests were undertaken under steady<br />

conditions with each duty pump operating at the specified design flow rate and<br />

water levels. When a single pump in operation it was conducted at lower water<br />

level of 260 mm (from the bottom sump) and at 400 mm water level when all<br />

major and minor pumps are in operation. Observations were made from the<br />

dosing of the blue dye at the entrance and immediately downstream of the<br />

6<br />

Institut Penyelidikan Hidraulik Kebangsaan Malaysia (NAHRIM)<br />

National Hydraulic Institute of Malaysia (NAHRIM)