mag

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Malaysia Water Research Journal<br />

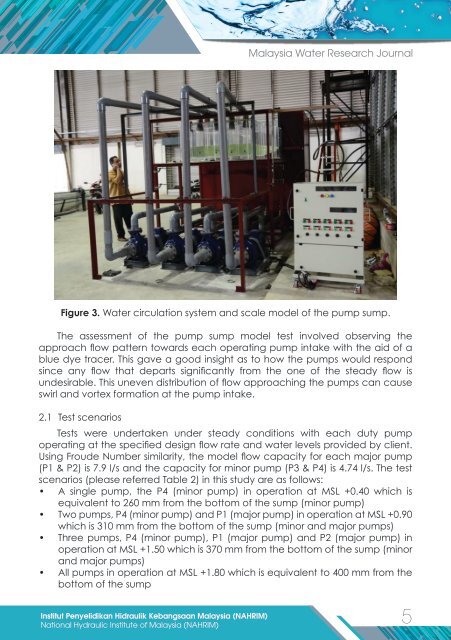

Figure 3. Water circulation system and scale model of the pump sump.<br />

The assessment of the pump sump model test involved observing the<br />

approach flow pattern towards each operating pump intake with the aid of a<br />

blue dye tracer. This gave a good insight as to how the pumps would respond<br />

since any flow that departs significantly from the one of the steady flow is<br />

undesirable. This uneven distribution of flow approaching the pumps can cause<br />

swirl and vortex formation at the pump intake.<br />

2.1 Test scenarios<br />

Tests were undertaken under steady conditions with each duty pump<br />

operating at the specified design flow rate and water levels provided by client.<br />

Using Froude Number similarity, the model flow capacity for each major pump<br />

(P1 & P2) is 7.9 l/s and the capacity for minor pump (P3 & P4) is 4.74 l/s. The test<br />

scenarios (please referred Table 2) in this study are as follows:<br />

• A single pump, the P4 (minor pump) in operation at MSL +0.40 which is<br />

equivalent to 260 mm from the bottom of the sump (minor pump)<br />

• Two pumps, P4 (minor pump) and P1 (major pump) in operation at MSL +0.90<br />

which is 310 mm from the bottom of the sump (minor and major pumps)<br />

• Three pumps, P4 (minor pump), P1 (major pump) and P2 (major pump) in<br />

operation at MSL +1.50 which is 370 mm from the bottom of the sump (minor<br />

and major pumps)<br />

• All pumps in operation at MSL +1.80 which is equivalent to 400 mm from the<br />

bottom of the sump<br />

Institut Penyelidikan Hidraulik Kebangsaan Malaysia (NAHRIM)<br />

5<br />

National Hydraulic Institute of Malaysia (NAHRIM)