St Mary Redcliffe Project 450 RIBA 2 Stage End Report

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

9 Mechanical Services <strong>St</strong>rategy<br />

9.1 Heating<br />

Insulation<br />

Passive Design Measures<br />

Reducing the U-values of external building elements will significantly reduce heat loss through<br />

the building fabric. This in turn will mean that less energy is required to condition the building.<br />

A U-value is a measure of heat loss. It is expressed in W/m²K and shows the amount of heat lost<br />

in watts (W) per square metre of material (for example wall, roof, floor etc.) per degree of<br />

temperature difference between indoor and outdoor temperatures in Kelvin. The lower the U-<br />

value, the better the insulation provided by the material.<br />

It will be very hard to improve the thermal performance of spaces within the church. The new build extensions however<br />

give a perfect opportunity to beyond current building regulation standards and even potentially looking at passivhaus<br />

methodology if zero carbon is on the agenda after the sustainability workshop. The below table shows the current<br />

proposed U-values compared to building regulation min standards.<br />

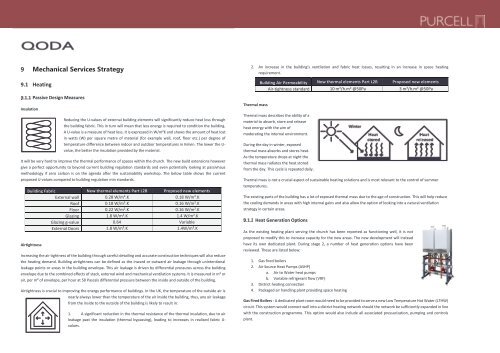

Building Fabric New thermal elements Part L2B Proposed new elements<br />

External wall 0.28 W/m².K 0.18 W/m².K<br />

Roof 0.18 W/m².K 0.16 W/m².K<br />

Floor 0.22 W/m².K 0.16 W/m².K<br />

Glazing 1.8 W/m².K 1.4 W/m².K<br />

Glazing g-value 0.64 Variable<br />

External Doors 1.8 W/m².K 1.4W/m².K<br />

Airtightness<br />

Increasing the air tightness of the building through careful detailing and accurate construction techniques will also reduce<br />

the heating demand. Building airtightness can be defined as the inward or outward air leakage through unintentional<br />

leakage points or areas in the building envelope. This air leakage is driven by differential pressures across the building<br />

envelope due to the combined effects of stack, external wind and mechanical ventilation systems. It is measured in m³ or<br />

air, per m² of envelope, per hour at 50 Pascals differential pressure between the inside and outside of the building.<br />

Airtightness is crucial to improving the energy performance of buildings. In the UK, the temperature of the outside air is<br />

nearly always lower than the temperature of the air inside the building, thus, any air leakage<br />

from the inside to the outside of the building is likely to result in:<br />

1. A significant reduction in the thermal resistance of the thermal insulation, due to air<br />

leakage past the insulation (thermal bypassing), leading to increases in realised fabric U-<br />

values.<br />

2. An increase in the building’s ventilation and fabric heat losses, resulting in an increase in space heating<br />

requirement.<br />

Thermal mass<br />

Thermal mass describes the ability of a<br />

material to absorb, store and release<br />

heat energy with the aim of<br />

moderating the internal environment.<br />

During the day in winter, exposed<br />

thermal mass absorbs and stores heat.<br />

As the temperature drops at night the<br />

thermal mass radiates the heat stored<br />

from the day. This cycle is repeated daily.<br />

Thermal mass is not a crucial aspect of sustainable heating solutions and is most relevant to the control of summer<br />

temperatures.<br />

The existing parts of the building has a lot of exposed thermal mass due to the age of construction. This will help reduce<br />

the cooling demands in areas with high internal gains and also allow the option of looking into a natural ventilation<br />

strategy in certain areas.<br />

Heat Generation Options<br />

As the existing heating plant serving the church has been reported as functioning well, it is not<br />

proposed to modify this to increase capacity for the new areas. The new development will instead<br />

have its own dedicated plant. During stage 2, a number of heat generation options have been<br />

reviewed. These are listed below:<br />

1. Gas fired boilers<br />

2. Air Source Heat Pumps (ASHP)<br />

a. Air to Water heat pumps<br />

b. Variable refrigerant flow (VRF)<br />

3. District heating connection<br />

4. Packaged air handling plant providing space heating<br />

Gas Fired Boilers - A dedicated plant room would need to be provided to serve a new Low Temperature Hot Water (LTHW)<br />

circuit. This system would connect well into a district heating network should the network be sufficiently expanded in line<br />

with the construction programme. This option would also include all associated pressurization, pumping and controls<br />

plant.<br />

Building Air Permeability New thermal elements Part L2B Proposed new elements<br />

Air-tightness standard 10 m³/h.m² @50Pa 3 m³/h.m² @50Pa<br />

1563.R1 – <strong>St</strong>age 2 report Page 14 of 29