INFLIGHT CATERING Process Analysis and User ... - IATA

INFLIGHT CATERING Process Analysis and User ... - IATA

INFLIGHT CATERING Process Analysis and User ... - IATA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

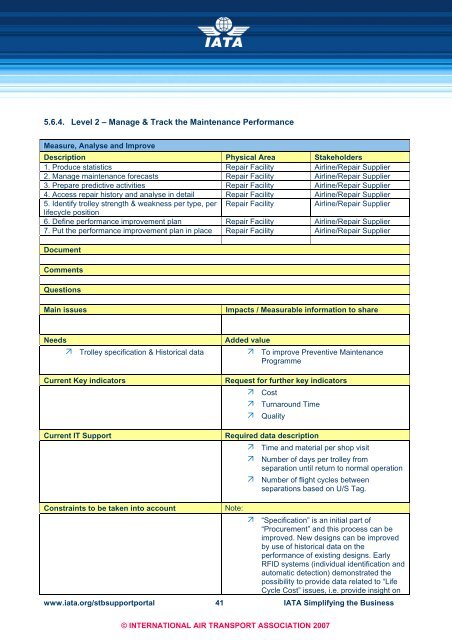

5.6.4. Level 2 – Manage & Track the Maintenance Performance<br />

Measure, Analyse <strong>and</strong> Improve<br />

Description Physical Area Stakeholders<br />

1. Produce statistics Repair Facility Airline/Repair Supplier<br />

2. Manage maintenance forecasts Repair Facility Airline/Repair Supplier<br />

3. Prepare predictive activities Repair Facility Airline/Repair Supplier<br />

4. Access repair history <strong>and</strong> analyse in detail Repair Facility Airline/Repair Supplier<br />

5. Identify trolley strength & weakness per type, per Repair Facility Airline/Repair Supplier<br />

lifecycle position<br />

6. Define performance improvement plan Repair Facility Airline/Repair Supplier<br />

7. Put the performance improvement plan in place Repair Facility Airline/Repair Supplier<br />

Document<br />

Comments<br />

Questions<br />

Main issues Impacts / Measurable information to share<br />

Needs Added value<br />

� Trolley specification & Historical data � To improve Preventive Maintenance<br />

Programme<br />

Current Key indicators Request for further key indicators<br />

� Cost<br />

� Turnaround Time<br />

� Quality<br />

Current IT Support Required data description<br />

� Time <strong>and</strong> material per shop visit<br />

� Number of days per trolley from<br />

separation until return to normal operation<br />

� Number of flight cycles between<br />

separations based on U/S Tag.<br />

Constraints to be taken into account Note:<br />

www.iata.org/stbsupportportal 41 <strong>IATA</strong> Simplifying the Business<br />

© INTERNATIONAL AIR TRANSPORT ASSOCIATION 2007<br />

�<br />

“Specification” is an initial part of<br />

“Procurement” <strong>and</strong> this process can be<br />

improved. New designs can be improved<br />

by use of historical data on the<br />

performance of existing designs. Early<br />

RFID systems (individual identification <strong>and</strong><br />

automatic detection) demonstrated the<br />

possibility to provide data related to “Life<br />

Cycle Cost” issues, i.e. provide insight on