Prospects of Colloidal Nanocrystals for Electronic - Computer Science

Prospects of Colloidal Nanocrystals for Electronic - Computer Science

Prospects of Colloidal Nanocrystals for Electronic - Computer Science

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

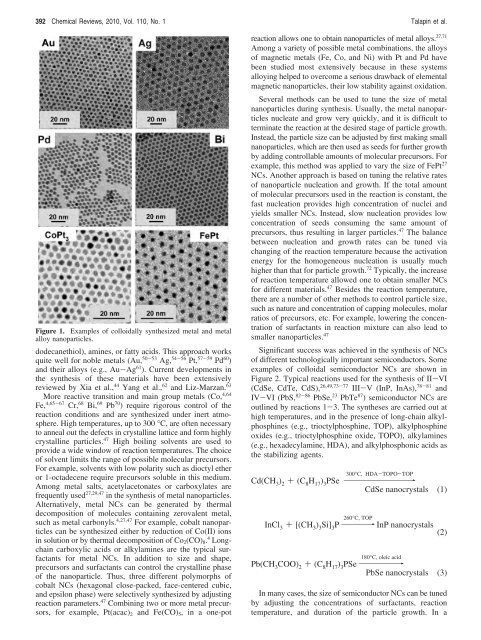

392 Chemical Reviews, 2010, Vol. 110, No. 1 Talapin et al.<br />

Figure 1. Examples <strong>of</strong> colloidally synthesized metal and metal<br />

alloy nanoparticles.<br />

dodecanethiol), amines, or fatty acids. This approach works<br />

quite well <strong>for</strong> noble metals (Au, 50-53 Ag, 54-56 Pt, 57-59 Pd 60 )<br />

and their alloys (e.g., Au-Ag 61 ). Current developments in<br />

the synthesis <strong>of</strong> these materials have been extensively<br />

reviewed by Xia et al., 44 Yang et al., 62 and Liz-Marzan. 63<br />

More reactive transition and main group metals (Co, 4,64<br />

Fe, 4,65-67 Cr, 68 Bi, 69 Pb 70 ) require rigorous control <strong>of</strong> the<br />

reaction conditions and are synthesized under inert atmosphere.<br />

High temperatures, up to 300 °C, are <strong>of</strong>ten necessary<br />

to anneal out the defects in crystalline lattice and <strong>for</strong>m highly<br />

crystalline particles. 47 High boiling solvents are used to<br />

provide a wide window <strong>of</strong> reaction temperatures. The choice<br />

<strong>of</strong> solvent limits the range <strong>of</strong> possible molecular precursors.<br />

For example, solvents with low polarity such as dioctyl ether<br />

or 1-octadecene require precursors soluble in this medium.<br />

Among metal salts, acetylacetonates or carboxylates are<br />

frequently used 27,29,47 in the synthesis <strong>of</strong> metal nanoparticles.<br />

Alternatively, metal NCs can be generated by thermal<br />

decomposition <strong>of</strong> molecules containing zerovalent metal,<br />

such as metal carbonyls. 4,27,47 For example, cobalt nanoparticles<br />

can be synthesized either by reduction <strong>of</strong> Co(II) ions<br />

in solution or by thermal decomposition <strong>of</strong> Co2(CO)8. 4 Longchain<br />

carboxylic acids or alkylamines are the typical surfactants<br />

<strong>for</strong> metal NCs. In addition to size and shape,<br />

precursors and surfactants can control the crystalline phase<br />

<strong>of</strong> the nanoparticle. Thus, three different polymorphs <strong>of</strong><br />

cobalt NCs (hexagonal close-packed, face-centered cubic,<br />

and epsilon phase) were selectively synthesized by adjusting<br />

reaction parameters. 47 Combining two or more metal precursors,<br />

<strong>for</strong> example, Pt(acac)2 and Fe(CO)5, in a one-pot<br />

reaction allows one to obtain nanoparticles <strong>of</strong> metal alloys. 27,71<br />

Among a variety <strong>of</strong> possible metal combinations, the alloys<br />

<strong>of</strong> magnetic metals (Fe, Co, and Ni) with Pt and Pd have<br />

been studied most extensively because in these systems<br />

alloying helped to overcome a serious drawback <strong>of</strong> elemental<br />

magnetic nanoparticles, their low stability against oxidation.<br />

Several methods can be used to tune the size <strong>of</strong> metal<br />

nanoparticles during synthesis. Usually, the metal nanoparticles<br />

nucleate and grow very quickly, and it is difficult to<br />

terminate the reaction at the desired stage <strong>of</strong> particle growth.<br />

Instead, the particle size can be adjusted by first making small<br />

nanoparticles, which are then used as seeds <strong>for</strong> further growth<br />

by adding controllable amounts <strong>of</strong> molecular precursors. For<br />

example, this method was applied to vary the size <strong>of</strong> FePt27 NCs. Another approach is based on tuning the relative rates<br />

<strong>of</strong> nanoparticle nucleation and growth. If the total amount<br />

<strong>of</strong> molecular precursors used in the reaction is constant, the<br />

fast nucleation provides high concentration <strong>of</strong> nuclei and<br />

yields smaller NCs. Instead, slow nucleation provides low<br />

concentration <strong>of</strong> seeds consuming the same amount <strong>of</strong><br />

precursors, thus resulting in larger particles. 47 The balance<br />

between nucleation and growth rates can be tuned via<br />

changing <strong>of</strong> the reaction temperature because the activation<br />

energy <strong>for</strong> the homogeneous nucleation is usually much<br />

higher than that <strong>for</strong> particle growth. 72 Typically, the increase<br />

<strong>of</strong> reaction temperature allowed one to obtain smaller NCs<br />

<strong>for</strong> different materials. 47 Besides the reaction temperature,<br />

there are a number <strong>of</strong> other methods to control particle size,<br />

such as nature and concentration <strong>of</strong> capping molecules, molar<br />

ratios <strong>of</strong> precursors, etc. For example, lowering the concentration<br />

<strong>of</strong> surfactants in reaction mixture can also lead to<br />

smaller nanoparticles. 47<br />

Significant success was achieved in the synthesis <strong>of</strong> NCs<br />

<strong>of</strong> different technologically important semiconductors. Some<br />

examples <strong>of</strong> colloidal semiconductor NCs are shown in<br />

Figure 2. Typical reactions used <strong>for</strong> the synthesis <strong>of</strong> II-VI<br />

(CdSe, CdTe, CdS), 26,49,73-77 III-V (InP, InAs), 78-81 and<br />

IV-VI (PbS, 82-86 PbSe, 23 PbTe87 ) semiconductor NCs are<br />

outlined by reactions 1-3. The syntheses are carried out at<br />

high temperatures, and in the presence <strong>of</strong> long-chain alkylphosphines<br />

(e.g., trioctylphosphine, TOP), alkylphosphine<br />

oxides (e.g., trioctylphosphine oxide, TOPO), alkylamines<br />

(e.g., hexadecylamine, HDA), and alkylphosphonic acids as<br />

the stabilizing agents.<br />

300°C, HDA-TOPO-TOP<br />

Cd(CH3 ) 2 + (C8H17 ) 3PSe98 CdSe nanocrystals (1)<br />

260°C, TOP<br />

InCl3 + [(CH3 ) 3Si] 3P98 InP nanocrystals (2)<br />

180°C, oleic acid<br />

Pb(CH3COO) 2 + (C8H17 ) 3PSe98 PbSe nanocrystals (3)<br />

In many cases, the size <strong>of</strong> semiconductor NCs can be tuned<br />

by adjusting the concentrations <strong>of</strong> surfactants, reaction<br />

temperature, and duration <strong>of</strong> the particle growth. In a