Prospects of Colloidal Nanocrystals for Electronic - Computer Science

Prospects of Colloidal Nanocrystals for Electronic - Computer Science

Prospects of Colloidal Nanocrystals for Electronic - Computer Science

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Colloidal</strong> <strong>Nanocrystals</strong> in <strong>Electronic</strong> Applications Chemical Reviews, 2010, Vol. 110, No. 1 447<br />

Si NCs embedded into Ge matrix. 666 Humphrey and Linke<br />

derived conditions under which reversible diffusive electron<br />

transport could be achieved in nanostructured thermoelectric<br />

materials. 667 Their work further supported the idea that deltafunctional<br />

density <strong>of</strong> states is optimal <strong>for</strong> thermoelectric<br />

materials and predicted that optimized nanostructured materials<br />

with a delta-like DOS may have ZT approaching 10 at<br />

room temperature. This exciting prediction originated from<br />

the fundamental difference between thermodynamics and<br />

transport in nanostructured materials as compared to bulk<br />

semiconductors. 667 In 2008, Mueller reported an encouraging<br />

theoretical study <strong>of</strong> TE behavior in an array <strong>of</strong> molecular<br />

junctions. 659<br />

The experimental studies <strong>of</strong> low-dimensional TE materials<br />

supported optimistic theoretical predictions. Harman et al.<br />

observed ZT ≈ 1.6 in a PbSeTe-based quantum dot superlattice<br />

grown by molecular beam epitaxy (MBE), 12 Venkatasubramanian<br />

et al. achieved ZT ≈ 2.4 in a p-type Bi2Te3/<br />

Sb2Te3 superlattice, 668 and Hsu et al. reported ZT ≈ 2.2 in<br />

alloys containing nanometer-sized metallic grains embedded<br />

in a semiconducting matrix. 669 In 2008, Heath et al. 670 and<br />

Yang et al. 671 reported very high ZT values measured <strong>for</strong><br />

individual Si nanowires. Most <strong>of</strong> these ZT enhancements<br />

were attributed to lowering the thermal conductance due to<br />

phonon scattering at the heterointerfaces and grain boundaries.<br />

However, until very recently, practical use <strong>of</strong> these<br />

materials was hampered by complicated and expensive<br />

synthesis techniques, such as molecular beam epitaxy. 12 In<br />

the last several years, important steps toward cost-effective<br />

nanostructured TE materials were reported. The Kanatzidis<br />

group synthesized several families <strong>of</strong> complex chalcogenide<br />

phases, such as n-type AgPb18+xSbTe20 (LAST) 669 and p-type<br />

Na0.95Pb20SbTe22 (SALT) 672 showing ZT values <strong>of</strong> ∼1.7 and<br />

1.6, respectively. These high ZT values originated from low<br />

thermal conductivity caused by the presence <strong>of</strong> nanoscale<br />

inclusions in the host material spontaneously <strong>for</strong>med due to<br />

phase separation during crystallization <strong>of</strong> melted phase. In<br />

2008, Poudel et al. reported a very intriguing discovery;<br />

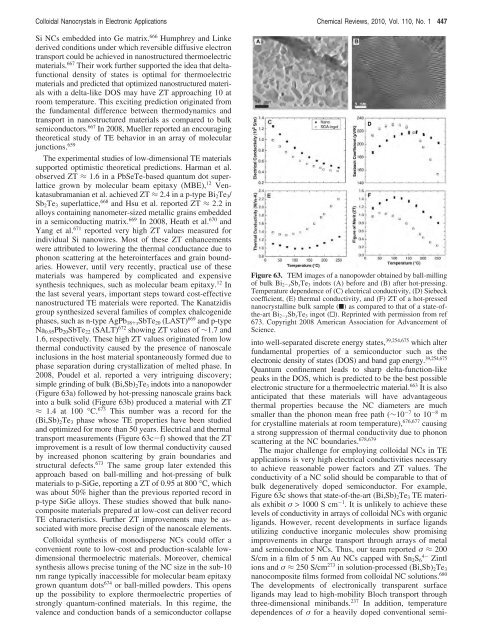

simple grinding <strong>of</strong> bulk (Bi,Sb)2Te3 indots into a nanopowder<br />

(Figure 63a) followed by hot-pressing nanoscale grains back<br />

into a bulk solid (Figure 63b) produced a material with ZT<br />

≈ 1.4 at 100 °C. 673 This number was a record <strong>for</strong> the<br />

(Bi,Sb)2Te3 phase whose TE properties have been studied<br />

and optimized <strong>for</strong> more than 50 years. Electrical and thermal<br />

transport measurements (Figure 63c-f) showed that the ZT<br />

improvement is a result <strong>of</strong> low thermal conductivity caused<br />

by increased phonon scattering by grain boundaries and<br />

structural defects. 673 The same group later extended this<br />

approach based on ball-milling and hot-pressing <strong>of</strong> bulk<br />

materials to p-SiGe, reporting a ZT <strong>of</strong> 0.95 at 800 °C, which<br />

was about 50% higher than the previous reported record in<br />

p-type SiGe alloys. These studies showed that bulk nanocomposite<br />

materials prepared at low-cost can deliver record<br />

TE characteristics. Further ZT improvements may be associated<br />

with more precise design <strong>of</strong> the nanoscale elements.<br />

<strong>Colloidal</strong> synthesis <strong>of</strong> monodisperse NCs could <strong>of</strong>fer a<br />

convenient route to low-cost and production-scalable lowdimensional<br />

thermoelectric materials. Moreover, chemical<br />

synthesis allows precise tuning <strong>of</strong> the NC size in the sub-10<br />

nm range typically inaccessible <strong>for</strong> molecular beam epitaxy<br />

grown quantum dots 674 or ball-milled powders. This opens<br />

up the possibility to explore thermoelectric properties <strong>of</strong><br />

strongly quantum-confined materials. In this regime, the<br />

valence and conduction bands <strong>of</strong> a semiconductor collapse<br />

into well-separated discrete energy states, 39,254,675 which alter<br />

fundamental properties <strong>of</strong> a semiconductor such as the<br />

electronic density <strong>of</strong> states (DOS) and band gap energy. 39,254,675<br />

Quantum confinement leads to sharp delta-function-like<br />

peaks in the DOS, which is predicted to be the best possible<br />

electronic structure <strong>for</strong> a thermoelectric material. 663 It is also<br />

anticipated that these materials will have advantageous<br />

thermal properties because the NC diameters are much<br />

smaller than the phonon mean free path (∼10-7 to 10-8 m<br />

<strong>for</strong> crystalline materials at room temperature), 676,677 causing<br />

a strong suppression <strong>of</strong> thermal conductivity due to phonon<br />

scattering at the NC boundaries. 678,679<br />

The major challenge <strong>for</strong> employing colloidal NCs in TE<br />

applications is very high electrical conductivities necessary<br />

to achieve reasonable power factors and ZT values. The<br />

conductivity <strong>of</strong> a NC solid should be comparable to that <strong>of</strong><br />

bulk degeneratively doped semiconductor. For example,<br />

Figure 63c shows that state-<strong>of</strong>-the-art (Bi,Sb)2Te3 TE materials<br />

exhibit σ > 1000 S cm-1 . It is unlikely to achieve these<br />

levels <strong>of</strong> conductivity in arrays <strong>of</strong> colloidal NCs with organic<br />

ligands. However, recent developments in surface ligands<br />

utilizing conductive inorganic molecules show promising<br />

improvements in charge transport through arrays <strong>of</strong> metal<br />

and semiconductor NCs. Thus, our team reported σ ≈ 200<br />

S/cm in a film <strong>of</strong> 5 nm Au NCs capped with Sn2S6 4- Zintl<br />

ions and σ ≈ 250 S/cm273 in solution-processed (Bi,Sb)2Te3<br />

nanocomposite films <strong>for</strong>med from colloidal NC solutions. 680<br />

The developments <strong>of</strong> electronically transparent surface<br />

ligands may lead to high-mobility Bloch transport through<br />

three-dimensional minibands. 237 Figure 63. TEM images <strong>of</strong> a nanopowder obtained by ball-milling<br />

<strong>of</strong> bulk Bi2-xSbxTe3 indots (A) be<strong>for</strong>e and (B) after hot-pressing.<br />

Temperature dependence <strong>of</strong> (C) electrical conductivity, (D) Siebeck<br />

coefficient, (E) thermal conductivity, and (F) ZT <strong>of</strong> a hot-pressed<br />

nanocrystalline bulk sample (9) as compared to that <strong>of</strong> a state-<strong>of</strong>the-art<br />

Bi2-xSbxTe3 ingot (0). Reprinted with permission from ref<br />

673. Copyright 2008 American Association <strong>for</strong> Advancement <strong>of</strong><br />

<strong>Science</strong>.<br />

In addition, temperature<br />

dependences <strong>of</strong> σ <strong>for</strong> a heavily doped conventional semi-