Guidance on the Control of Odour and Noise from ... - Defra

Guidance on the Control of Odour and Noise from ... - Defra

Guidance on the Control of Odour and Noise from ... - Defra

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

For <strong>the</strong> purpose <strong>of</strong> dealing with an odour problem <strong>the</strong> main area <strong>of</strong> c<strong>on</strong>cern will be<br />

those extracts located over cooking areas as this will c<strong>on</strong>tain <strong>the</strong> most c<strong>on</strong>centrated<br />

cooking odour. The level <strong>of</strong> odour that may be found within a general room extract<br />

system will c<strong>on</strong>tain more dilute odour <strong>and</strong> <strong>the</strong>refore will be harder to treat.<br />

<strong>Noise</strong> problems can arise equally <strong>from</strong> any part <strong>of</strong> a mechanical ventilati<strong>on</strong> system.<br />

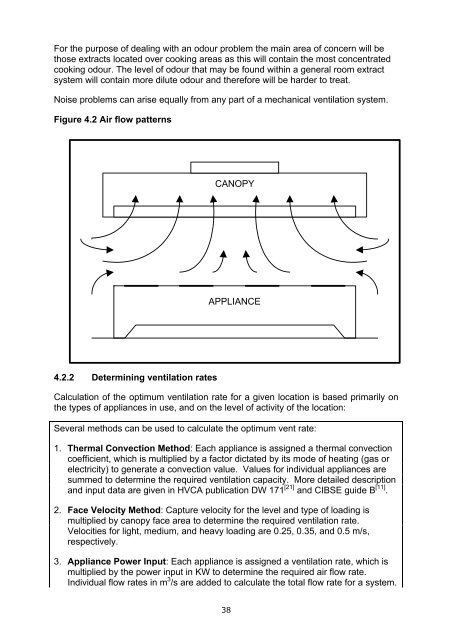

Figure 4.2 Air flow patterns<br />

4.2.2 Determining ventilati<strong>on</strong> rates<br />

CANOPY<br />

APPLIANCE<br />

Calculati<strong>on</strong> <strong>of</strong> <strong>the</strong> optimum ventilati<strong>on</strong> rate for a given locati<strong>on</strong> is based primarily <strong>on</strong><br />

<strong>the</strong> types <strong>of</strong> appliances in use, <strong>and</strong> <strong>on</strong> <strong>the</strong> level <strong>of</strong> activity <strong>of</strong> <strong>the</strong> locati<strong>on</strong>:<br />

Several methods can be used to calculate <strong>the</strong> optimum vent rate:<br />

1. Thermal C<strong>on</strong>vecti<strong>on</strong> Method: Each appliance is assigned a <strong>the</strong>rmal c<strong>on</strong>vecti<strong>on</strong><br />

coefficient, which is multiplied by a factor dictated by its mode <strong>of</strong> heating (gas or<br />

electricity) to generate a c<strong>on</strong>vecti<strong>on</strong> value. Values for individual appliances are<br />

summed to determine <strong>the</strong> required ventilati<strong>on</strong> capacity. More detailed descripti<strong>on</strong><br />

<strong>and</strong> input data are given in HVCA publicati<strong>on</strong> DW 171 [21] <strong>and</strong> CIBSE guide B [11] .<br />

2. Face Velocity Method: Capture velocity for <strong>the</strong> level <strong>and</strong> type <strong>of</strong> loading is<br />

multiplied by canopy face area to determine <strong>the</strong> required ventilati<strong>on</strong> rate.<br />

Velocities for light, medium, <strong>and</strong> heavy loading are 0.25, 0.35, <strong>and</strong> 0.5 m/s,<br />

respectively.<br />

3. Appliance Power Input: Each appliance is assigned a ventilati<strong>on</strong> rate, which is<br />

multiplied by <strong>the</strong> power input in KW to determine <strong>the</strong> required air flow rate.<br />

Individual flow rates in m 3 /s are added to calculate <strong>the</strong> total flow rate for a system.<br />

38