Guidance on the Control of Odour and Noise from ... - Defra

Guidance on the Control of Odour and Noise from ... - Defra

Guidance on the Control of Odour and Noise from ... - Defra

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

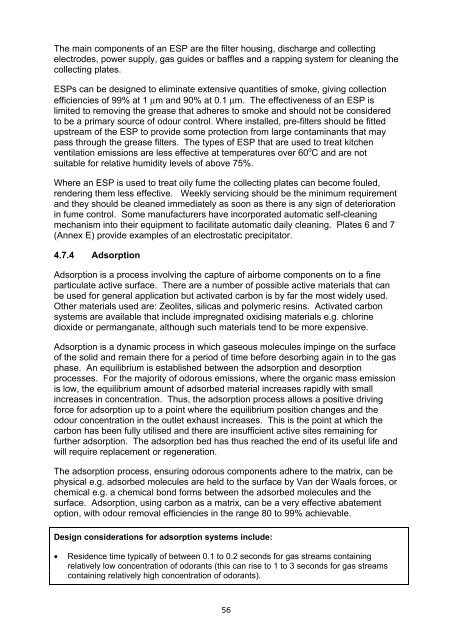

The main comp<strong>on</strong>ents <strong>of</strong> an ESP are <strong>the</strong> filter housing, discharge <strong>and</strong> collecting<br />

electrodes, power supply, gas guides or baffles <strong>and</strong> a rapping system for cleaning <strong>the</strong><br />

collecting plates.<br />

ESPs can be designed to eliminate extensive quantities <strong>of</strong> smoke, giving collecti<strong>on</strong><br />

efficiencies <strong>of</strong> 99% at 1 µm <strong>and</strong> 90% at 0.1 µm. The effectiveness <strong>of</strong> an ESP is<br />

limited to removing <strong>the</strong> grease that adheres to smoke <strong>and</strong> should not be c<strong>on</strong>sidered<br />

to be a primary source <strong>of</strong> odour c<strong>on</strong>trol. Where installed, pre-filters should be fitted<br />

upstream <strong>of</strong> <strong>the</strong> ESP to provide some protecti<strong>on</strong> <strong>from</strong> large c<strong>on</strong>taminants that may<br />

pass through <strong>the</strong> grease filters. The types <strong>of</strong> ESP that are used to treat kitchen<br />

ventilati<strong>on</strong> emissi<strong>on</strong>s are less effective at temperatures over 60 o C <strong>and</strong> are not<br />

suitable for relative humidity levels <strong>of</strong> above 75%.<br />

Where an ESP is used to treat oily fume <strong>the</strong> collecting plates can become fouled,<br />

rendering <strong>the</strong>m less effective. Weekly servicing should be <strong>the</strong> minimum requirement<br />

<strong>and</strong> <strong>the</strong>y should be cleaned immediately as so<strong>on</strong> as <strong>the</strong>re is any sign <strong>of</strong> deteriorati<strong>on</strong><br />

in fume c<strong>on</strong>trol. Some manufacturers have incorporated automatic self-cleaning<br />

mechanism into <strong>the</strong>ir equipment to facilitate automatic daily cleaning. Plates 6 <strong>and</strong> 7<br />

(Annex E) provide examples <strong>of</strong> an electrostatic precipitator.<br />

4.7.4 Adsorpti<strong>on</strong><br />

Adsorpti<strong>on</strong> is a process involving <strong>the</strong> capture <strong>of</strong> airborne comp<strong>on</strong>ents <strong>on</strong> to a fine<br />

particulate active surface. There are a number <strong>of</strong> possible active materials that can<br />

be used for general applicati<strong>on</strong> but activated carb<strong>on</strong> is by far <strong>the</strong> most widely used.<br />

O<strong>the</strong>r materials used are: Zeolites, silicas <strong>and</strong> polymeric resins. Activated carb<strong>on</strong><br />

systems are available that include impregnated oxidising materials e.g. chlorine<br />

dioxide or permanganate, although such materials tend to be more expensive.<br />

Adsorpti<strong>on</strong> is a dynamic process in which gaseous molecules impinge <strong>on</strong> <strong>the</strong> surface<br />

<strong>of</strong> <strong>the</strong> solid <strong>and</strong> remain <strong>the</strong>re for a period <strong>of</strong> time before desorbing again in to <strong>the</strong> gas<br />

phase. An equilibrium is established between <strong>the</strong> adsorpti<strong>on</strong> <strong>and</strong> desorpti<strong>on</strong><br />

processes. For <strong>the</strong> majority <strong>of</strong> odorous emissi<strong>on</strong>s, where <strong>the</strong> organic mass emissi<strong>on</strong><br />

is low, <strong>the</strong> equilibrium amount <strong>of</strong> adsorbed material increases rapidly with small<br />

increases in c<strong>on</strong>centrati<strong>on</strong>. Thus, <strong>the</strong> adsorpti<strong>on</strong> process allows a positive driving<br />

force for adsorpti<strong>on</strong> up to a point where <strong>the</strong> equilibrium positi<strong>on</strong> changes <strong>and</strong> <strong>the</strong><br />

odour c<strong>on</strong>centrati<strong>on</strong> in <strong>the</strong> outlet exhaust increases. This is <strong>the</strong> point at which <strong>the</strong><br />

carb<strong>on</strong> has been fully utilised <strong>and</strong> <strong>the</strong>re are insufficient active sites remaining for<br />

fur<strong>the</strong>r adsorpti<strong>on</strong>. The adsorpti<strong>on</strong> bed has thus reached <strong>the</strong> end <strong>of</strong> its useful life <strong>and</strong><br />

will require replacement or regenerati<strong>on</strong>.<br />

The adsorpti<strong>on</strong> process, ensuring odorous comp<strong>on</strong>ents adhere to <strong>the</strong> matrix, can be<br />

physical e.g. adsorbed molecules are held to <strong>the</strong> surface by Van der Waals forces, or<br />

chemical e.g. a chemical b<strong>on</strong>d forms between <strong>the</strong> adsorbed molecules <strong>and</strong> <strong>the</strong><br />

surface. Adsorpti<strong>on</strong>, using carb<strong>on</strong> as a matrix, can be a very effective abatement<br />

opti<strong>on</strong>, with odour removal efficiencies in <strong>the</strong> range 80 to 99% achievable.<br />

Design c<strong>on</strong>siderati<strong>on</strong>s for adsorpti<strong>on</strong> systems include:<br />

• Residence time typically <strong>of</strong> between 0.1 to 0.2 sec<strong>on</strong>ds for gas streams c<strong>on</strong>taining<br />

relatively low c<strong>on</strong>centrati<strong>on</strong> <strong>of</strong> odorants (this can rise to 1 to 3 sec<strong>on</strong>ds for gas streams<br />

c<strong>on</strong>taining relatively high c<strong>on</strong>centrati<strong>on</strong> <strong>of</strong> odorants).<br />

56