Guidance on the Control of Odour and Noise from ... - Defra

Guidance on the Control of Odour and Noise from ... - Defra

Guidance on the Control of Odour and Noise from ... - Defra

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

c<strong>on</strong>tributory factor in poor performance <strong>of</strong> grease <strong>and</strong> odour removal systems is <strong>the</strong><br />

inadequacy <strong>of</strong> <strong>the</strong> maintenance schedule applied to equipment. The optimum<br />

maintenance period will depend <strong>on</strong> <strong>the</strong> capacity <strong>of</strong> <strong>the</strong> equipment installed. It is fair to<br />

say that most kitchen ventilati<strong>on</strong> systems are designed with very little excess<br />

capacity.<br />

A key c<strong>on</strong>siderati<strong>on</strong> in <strong>the</strong> performance <strong>of</strong> <strong>the</strong> kitchen ventilati<strong>on</strong> system is <strong>the</strong> buildup<br />

<strong>of</strong> debris within <strong>the</strong> ductwork itself. Good hygiene practice should ensure that <strong>the</strong><br />

face <strong>of</strong> <strong>the</strong> canopy, filters <strong>and</strong> any o<strong>the</strong>r parts requiring cleaning are cleaned regularly<br />

to comply with <strong>the</strong> Food Safety (General Food Hygiene) Regulati<strong>on</strong>s 1995 [20] . It is<br />

unlikely however that such cleaning will be afforded to <strong>the</strong> ductwork bey<strong>on</strong>d <strong>the</strong><br />

canopy <strong>and</strong> coarse grease filtrati<strong>on</strong> system. Material adhering to any o<strong>the</strong>r internal<br />

surfaces within <strong>the</strong> duct will c<strong>on</strong>tribute to <strong>the</strong> overall odour emissi<strong>on</strong> <strong>from</strong> <strong>the</strong><br />

premises. This feature is comm<strong>on</strong> with poorly maintained ventilati<strong>on</strong> systems <strong>of</strong> any<br />

kind <strong>and</strong> will lead to increased <strong>and</strong> unnecessary loading <strong>on</strong> any arrestment<br />

equipment <strong>and</strong> can lead to corrosi<strong>on</strong> <strong>of</strong> <strong>the</strong> ductwork itself. In extreme circumstances<br />

excess debris within a duct work system can be seen as grease <strong>and</strong> dirt<br />

accumulati<strong>on</strong>s around seals <strong>and</strong> joints in <strong>the</strong> ductwork. This debris is combustible are<br />

<strong>the</strong>refore is a potential fire hazard.<br />

Poor maintenance <strong>of</strong> ventilati<strong>on</strong> systems can also lead to noise complaints. These<br />

are <strong>of</strong>ten attributed to worn bearings, imbalance due to erosi<strong>on</strong> or damage, dust <strong>and</strong><br />

deposits <strong>on</strong> <strong>the</strong> impeller <strong>and</strong> in <strong>the</strong> adjacent ductwork. Additi<strong>on</strong>ally, silencers may be<br />

damaged, eroded, corroded or clogged <strong>and</strong> flexible c<strong>on</strong>nectors may become brittle or<br />

stiff.<br />

4.11.2 Recommendati<strong>on</strong>s for maintenance<br />

Maintenance <strong>of</strong> <strong>the</strong> kitchen equipment should be carried out in order to ensure <strong>the</strong><br />

system remains as efficient as possible <strong>and</strong> also to ensure that <strong>the</strong> ventilati<strong>on</strong> plant<br />

remains in good c<strong>on</strong>diti<strong>on</strong>.<br />

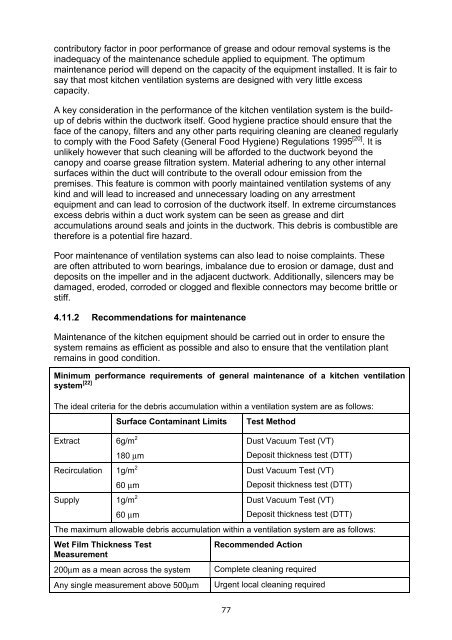

Minimum performance requirements <strong>of</strong> general maintenance <strong>of</strong> a kitchen ventilati<strong>on</strong><br />

system [22]<br />

The ideal criteria for <strong>the</strong> debris accumulati<strong>on</strong> within a ventilati<strong>on</strong> system are as follows:<br />

Extract<br />

Surface C<strong>on</strong>taminant Limits Test Method<br />

6g/m 2<br />

180 µm<br />

Recirculati<strong>on</strong> 1g/m 2<br />

Supply<br />

60 µm<br />

1g/m 2<br />

60 µm<br />

77<br />

Dust Vacuum Test (VT)<br />

Deposit thickness test (DTT)<br />

Dust Vacuum Test (VT)<br />

Deposit thickness test (DTT)<br />

Dust Vacuum Test (VT)<br />

Deposit thickness test (DTT)<br />

The maximum allowable debris accumulati<strong>on</strong> within a ventilati<strong>on</strong> system are as follows:<br />

Wet Film Thickness Test<br />

Measurement<br />

Recommended Acti<strong>on</strong><br />

200µm as a mean across <strong>the</strong> system Complete cleaning required<br />

Any single measurement above 500µm Urgent local cleaning required