Põllumajandusministeeriumi ja Maaelu ... - bioenergybaltic

Põllumajandusministeeriumi ja Maaelu ... - bioenergybaltic

Põllumajandusministeeriumi ja Maaelu ... - bioenergybaltic

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

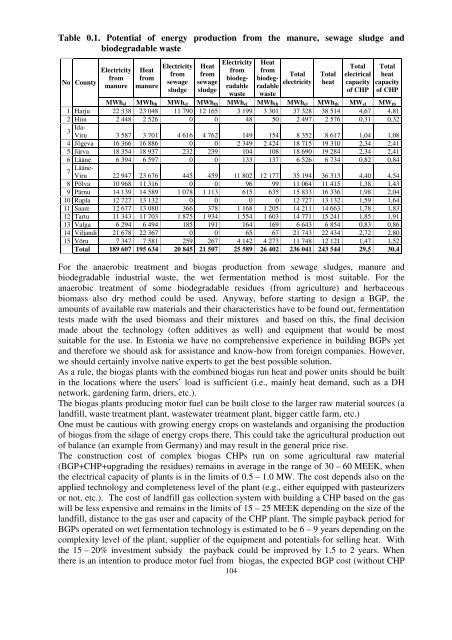

Table 0.1. Potential of energy production from the manure, sewage sludge and<br />

biodegradable waste<br />

No County<br />

Electricity<br />

from<br />

manure<br />

Heat<br />

from<br />

manure<br />

Electricity<br />

from<br />

sewage<br />

sludge<br />

Heat<br />

from<br />

sewage<br />

sludge<br />

Electricity<br />

from<br />

biodegradable<br />

waste<br />

104<br />

Heat<br />

from<br />

biodegradable<br />

waste<br />

Total<br />

electricity<br />

Total<br />

heat<br />

Total<br />

electrical<br />

capacity<br />

of CHP<br />

Total<br />

heat<br />

capacity<br />

of CHP<br />

MWh el MWh th MWh el MWh th MWh el MWh th MWh el MWh th MW el MW th<br />

1 Harju 22 338 23 048 11 790 12 165 3 199 3 301 37 328 38 514 4,67 4,81<br />

2 Hiiu 2 448 2 526 0 0 48 50 2 497 2 576 0,31 0,32<br />

3 Ida-<br />

Viru 3 587 3 701 4 616 4 762 149 154 8 352 8 617 1,04 1,08<br />

4 Jõgeva 16 366 16 886 0 0 2 349 2 424 18 715 19 310 2,34 2,41<br />

5 Järva 18 354 18 937 232 239 104 108 18 690 19 284 2,34 2,41<br />

6 Lääne 6 394 6 597 0 0 133 137 6 526 6 734 0,82 0,84<br />

7 Lääne-<br />

Viru 22 947 23 676 445 459 11 802 12 177 35 194 36 313 4,40 4,54<br />

8 Põlva 10 968 11 316 0 0 96 99 11 064 11 415 1,38 1,43<br />

9 Pärnu 14 139 14 589 1 078 1 113 615 635 15 833 16 336 1,98 2,04<br />

10 Rapla 12 727 13 132 0 0 0 0 12 727 13 132 1,59 1,64<br />

11 Saare 12 677 13 080 366 378 1 168 1 205 14 211 14 663 1,78 1,83<br />

12 Tartu 11 343 11 703 1 875 1 934 1 554 1 603 14 771 15 241 1,85 1,91<br />

13 Valga 6 294 6 494 185 191 164 169 6 643 6 854 0,83 0,86<br />

14 Vil<strong>ja</strong>ndi 21 678 22 367 0 0 65 67 21 743 22 434 2,72 2,80<br />

15 Võru 7 347 7 581 259 267 4 142 4 273 11 748 12 121 1,47 1,52<br />

Total 189 607 195 634 20 845 21 507 25 589 26 402 236 041 243 544 29,5 30,4<br />

For the anaerobic treatment and biogas production from sewage sludges, manure and<br />

biodegradable industrial waste, the wet fermentation method is most suitable. For the<br />

anaerobic treatment of some biodegradable residues (from agriculture) and herbaceous<br />

biomass also dry method could be used. Anyway, before starting to design a BGP, the<br />

amounts of available raw materials and their characteristics have to be found out, fermentation<br />

tests made with the used biomass and their mixtures and based on this, the final decision<br />

made about the technology (often additives as well) and equipment that would be most<br />

suitable for the use. In Estonia we have no comprehensive experience in building BGPs yet<br />

and therefore we should ask for assistance and know-how from foreign companies. However,<br />

we should certainly involve native experts to get the best possible solution.<br />

As a rule, the biogas plants with the combined biogas run heat and power units should be built<br />

in the locations where the users’ load is sufficient (i.e., mainly heat demand, such as a DH<br />

network, gardening farm, driers, etc.).<br />

The biogas plants producing motor fuel can be built close to the larger raw material sources (a<br />

landfill, waste treatment plant, wastewater treatment plant, bigger cattle farm, etc.)<br />

One must be cautious with growing energy crops on wastelands and organising the production<br />

of biogas from the silage of energy crops there. This could take the agricultural production out<br />

of balance (an example from Germany) and may result in the general price rise.<br />

The construction cost of complex biogas CHPs run on some agricultural raw material<br />

(BGP+CHP+upgrading the residues) remains in average in the range of 30 – 60 MEEK, when<br />

the electrical capacity of plants is in the limits of 0.5 – 1.0 MW. The cost depends also on the<br />

applied technology and completeness level of the plant (e.g., either equipped with pasteurizers<br />

or not, etc.). The cost of landfill gas collection system with building a CHP based on the gas<br />

will be less expensive and remains in the limits of 15 – 25 MEEK depending on the size of the<br />

landfill, distance to the gas user and capacity of the CHP plant. The simple payback period for<br />

BGPs operated on wet fermentation technology is estimated to be 6 – 9 years depending on the<br />

complexity level of the plant, supplier of the equipment and potentials for selling heat. With<br />

the 15 – 20% investment subsidy the payback could be improved by 1.5 to 2 years. When<br />

there is an intention to produce motor fuel from biogas, the expected BGP cost (without CHP