Tender Documents - Oil India Limited

Tender Documents - Oil India Limited

Tender Documents - Oil India Limited

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

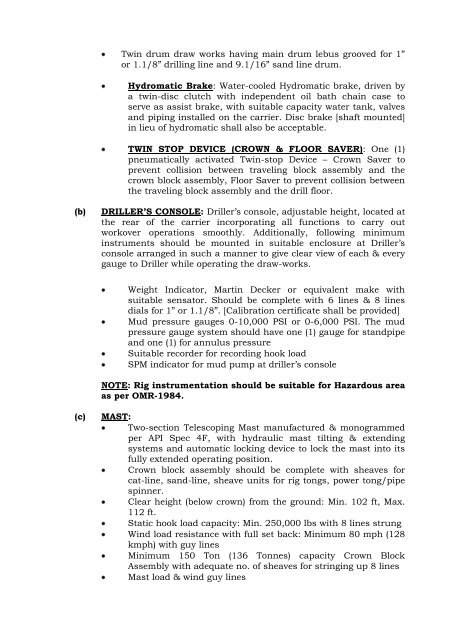

Twin drum draw works having main drum lebus grooved for 1”<br />

or 1.1/8” drilling line and 9.1/16” sand line drum.<br />

Hydromatic Brake: Water-cooled Hydromatic brake, driven by<br />

a twin-disc clutch with independent oil bath chain case to<br />

serve as assist brake, with suitable capacity water tank, valves<br />

and piping installed on the carrier. Disc brake [shaft mounted]<br />

in lieu of hydromatic shall also be acceptable.<br />

TWIN STOP DEVICE (CROWN & FLOOR SAVER): One (1)<br />

pneumatically activated Twin-stop Device – Crown Saver to<br />

prevent collision between traveling block assembly and the<br />

crown block assembly, Floor Saver to prevent collision between<br />

the traveling block assembly and the drill floor.<br />

(b)<br />

DRILLER’S CONSOLE: Driller‟s console, adjustable height, located at<br />

the rear of the carrier incorporating all functions to carry out<br />

workover operations smoothly. Additionally, following minimum<br />

instruments should be mounted in suitable enclosure at Driller‟s<br />

console arranged in such a manner to give clear view of each & every<br />

gauge to Driller while operating the draw-works.<br />

Weight Indicator, Martin Decker or equivalent make with<br />

suitable sensator. Should be complete with 6 lines & 8 lines<br />

dials for 1” or 1.1/8”. [Calibration certificate shall be provided]<br />

Mud pressure gauges 0-10,000 PSI or 0-6,000 PSI. The mud<br />

pressure gauge system should have one (1) gauge for standpipe<br />

and one (1) for annulus pressure<br />

Suitable recorder for recording hook load<br />

SPM indicator for mud pump at driller‟s console<br />

NOTE: Rig instrumentation should be suitable for Hazardous area<br />

as per OMR-1984.<br />

(c)<br />

MAST:<br />

Two-section Telescoping Mast manufactured & monogrammed<br />

per API Spec 4F, with hydraulic mast tilting & extending<br />

systems and automatic locking device to lock the mast into its<br />

fully extended operating position.<br />

Crown block assembly should be complete with sheaves for<br />

cat-line, sand-line, sheave units for rig tongs, power tong/pipe<br />

spinner.<br />

Clear height (below crown) from the ground: Min. 102 ft, Max.<br />

112 ft.<br />

Static hook load capacity: Min. 250,000 lbs with 8 lines strung<br />

Wind load resistance with full set back: Minimum 80 mph (128<br />

kmph) with guy lines<br />

Minimum 150 Ton (136 Tonnes) capacity Crown Block<br />

Assembly with adequate no. of sheaves for stringing up 8 lines<br />

Mast load & wind guy lines