- Page 1:

VERSAMARK VL2000 Printing System VL

- Page 4 and 5:

FCC Compliance Statement This equip

- Page 6 and 7:

Scope Text Notations This manual us

- Page 9 and 10:

Contents Changes in this Version ..

- Page 11 and 12:

Contents Monitoring Operations.....

- Page 13 and 14:

Figures Figure 1 VL2000 modules....

- Page 15 and 16:

Contents Figures Figure 101 Line ho

- Page 17 and 18:

Chapter 1. Operator Controls The KO

- Page 19 and 20:

The System Controller and Its Windo

- Page 21 and 22:

The System Controller and Its Windo

- Page 23 and 24:

The System Controller and Its Windo

- Page 25 and 26:

The System Controller and Its Windo

- Page 27 and 28:

The System Controller and Its Windo

- Page 29 and 30:

Displaying Print Station Informatio

- Page 31 and 32:

Displaying Print Station Informatio

- Page 33 and 34:

Displaying Print Station Informatio

- Page 35 and 36:

Displaying Print Station Informatio

- Page 37 and 38:

Related Software IJ Data Prep Relat

- Page 39 and 40:

Related Software IJPDS Proofer IJPD

- Page 41 and 42:

Print Stations Print Stations The p

- Page 43 and 44:

Unwind Unit Unwind Unit The unwind

- Page 45 and 46:

Unwind Unit Figure 8 Unwind unit, p

- Page 47 and 48:

Unwind Unit A blue light around the

- Page 49 and 50:

Unwind Unit Drag bar A stationary b

- Page 51 and 52:

Print Tower Controls Web Guide Modu

- Page 53 and 54:

Print Tower Controls Print Tower Co

- Page 55 and 56:

Print Tower Controls Web cleaner bo

- Page 57 and 58:

Print Tower Controls Outfeed Module

- Page 59 and 60:

Rewind Unit Rewind Unit The rewind

- Page 61 and 62:

Rewind Unit External Power and Air

- Page 63 and 64:

Rewind Unit External Power and Air

- Page 65 and 66:

Chapter 2. Basic Operations Every o

- Page 67 and 68:

Operations Overview System Setup Pr

- Page 69 and 70:

Operations Overview Printhead Opera

- Page 71 and 72:

Operations Overview Printhead Opera

- Page 73 and 74:

Preliminary Operations Turning the

- Page 75 and 76:

Preliminary Operations Turning the

- Page 77 and 78:

Starting the System Controller Stan

- Page 79 and 80:

Operator Access to Controller Funct

- Page 81 and 82:

Powering the Print Station Off Powe

- Page 83 and 84:

Turning the Printing System Off Fig

- Page 85 and 86:

Turning the Printing System Off Fig

- Page 87 and 88:

Raising and Lowering the Print Towe

- Page 89 and 90:

Changing Paper Rolls at the Unwind

- Page 91 and 92:

Changing Paper Rolls at the Unwind

- Page 93 and 94:

Changing Paper Rolls at the Unwind

- Page 95 and 96:

Roll Position on the Shaft Figure 5

- Page 97 and 98:

Changing Paper Rolls at the Rewind

- Page 99 and 100:

Changing Paper Rolls at the Rewind

- Page 101 and 102:

Webbing the Unwind Unit Figure 58 W

- Page 103 and 104:

Jogging the Web Jogging the Web 1.

- Page 105 and 106:

Adjusting the Gripper Rollers Adjus

- Page 107 and 108:

Center positioning Center positioni

- Page 109 and 110:

Webbing the Web Cleaner Figure 64 W

- Page 111 and 112:

Webbing the Dryer Webbing the Dryer

- Page 113 and 114:

Webbing the Dryer Figure 67 Dryer w

- Page 115 and 116:

Webbing the Turnbar Webbing the Tur

- Page 117 and 118:

Webbing the Rewind Unit Webbing the

- Page 119 and 120:

Webbing the Rewind Unit 6. Feed eno

- Page 121 and 122:

Selecting the Motor Direction Selec

- Page 123 and 124:

Tightening the Web Use this procedu

- Page 125 and 126:

Positioning the Cue Sensor Position

- Page 127 and 128:

Printhead Activities Moving a Print

- Page 129 and 130:

Enabling an Existing Printhead Enab

- Page 131 and 132:

Setting Up Cue Mark Printing Settin

- Page 133 and 134:

Job Setup Setting Up a Print Job 5.

- Page 135 and 136:

Job Setup Setting Up a Print Job 13

- Page 137 and 138:

Job Setup Setting Up a Print Job 23

- Page 139 and 140:

Adjusting the Data Registration (Y-

- Page 141 and 142:

Adjusting the Lateral Image Positio

- Page 143 and 144:

Adjusting the Duplexed Registration

- Page 145 and 146:

Printhead Registration Printhead Re

- Page 147 and 148:

Printhead Registration VL2000 test

- Page 149 and 150:

Printhead Registration Always adjus

- Page 151 and 152:

Setting Up Page Correlation Setting

- Page 153 and 154:

Setting Up Page Correlation Setting

- Page 155 and 156:

Setting Up Page Correlation Setting

- Page 157 and 158:

Saving the Job Settings Saving the

- Page 159 and 160:

Print Operations Displaying Printhe

- Page 161 and 162:

Readying Printheads to Print Readyi

- Page 163 and 164:

Monitoring Operations • Red circl

- Page 165 and 166:

Preventing Printhead Problems Preve

- Page 167 and 168:

Print Job Operations Aligning the L

- Page 169 and 170:

Print Job Operations Aligning the L

- Page 171 and 172:

Adjusting the Dryer Temperature Adj

- Page 173 and 174:

Start Up Procedure Start Up Procedu

- Page 175 and 176:

Reprinting Data ! DANGER Stay clear

- Page 177 and 178:

Running Jobs with Job Spooling Runn

- Page 179 and 180:

Running Jobs with Job Spooling The

- Page 181 and 182:

Selecting a New Printing Speed Sele

- Page 183 and 184:

Splicing the Web Figure 85 Tear the

- Page 185 and 186:

Splicing the Web DANGER Danger of c

- Page 187 and 188:

External Fluid Container Procedure

- Page 189 and 190:

Replacing the Replenisher or Cleane

- Page 191 and 192:

Disposing of Waste Fluid Disposal G

- Page 193 and 194:

Chapter 3. Advanced Operations Only

- Page 195 and 196:

Baseline System Numbering Baseline

- Page 197 and 198:

Multiple Print Tower Numbering If n

- Page 199 and 200:

Multiple Print Tower Numbering 9. S

- Page 201 and 202:

Defining Print Station INet Address

- Page 203 and 204:

Identifying Printheads Identifying

- Page 205 and 206:

Identifying Printheads 4. Drag all

- Page 207 and 208:

System Setup of Optional Functions

- Page 209 and 210:

System Setup of Optional Functions

- Page 211 and 212:

System Setup of Optional Functions

- Page 213 and 214:

System Setup of Optional Functions

- Page 215 and 216:

System Setup of Optional Functions

- Page 217 and 218:

Setting Up the Activities and Users

- Page 219 and 220:

Setting Up the Activities and Users

- Page 221 and 222:

Setting Up the Job for Production T

- Page 223 and 224:

Logging In Logging In If the CS410

- Page 225 and 226:

Logging Out Logging Out While opera

- Page 227 and 228:

Changing a Stop Reason Changing a S

- Page 229 and 230:

How Read and Print Works How Read a

- Page 231 and 232:

Positioning the Reader Positioning

- Page 233 and 234:

Setting Up the Job Queue and Print

- Page 235 and 236:

Setting Up the Job Queue • Keep r

- Page 237 and 238:

Setting Up the Job Queue or simplex

- Page 239 and 240:

Setting Up the Job Queue Figure 99

- Page 241 and 242:

Using an MPC Manual Setup Making De

- Page 243 and 244:

Using an MPC Manual Setup Making De

- Page 245 and 246:

Using an MPC Manual Setup Overridin

- Page 247 and 248: Using an MPC Manual Setup Overridin

- Page 249 and 250: Using an MPC Manual Setup Overridin

- Page 251 and 252: Setting Up the Line Hole Sensor Fig

- Page 253 and 254: Adjusting the Cue Sensor Adjusting

- Page 255 and 256: Setting the Cue Delays Setting the

- Page 257 and 258: Setting the Cue Delays Field Value/

- Page 259 and 260: Setting the Cue Delays f. Enter inf

- Page 261 and 262: Calculating the Speed Comp Value 1.

- Page 263 and 264: Placing the Page Correlation Marks

- Page 265 and 266: Using Special Cueing Using Special

- Page 267 and 268: Implementing Special Cueing Impleme

- Page 269 and 270: Operational Modes Entering Key Oper

- Page 271 and 272: Operational Modes Exiting Key Opera

- Page 273 and 274: Retrieving Accounting Information V

- Page 275 and 276: Replace and Packing Removing the Pr

- Page 277 and 278: Replace and Packing Removing the Pr

- Page 279 and 280: Replace and Packing Removing the Pr

- Page 281 and 282: Packing the Printhead Figure 113 Sh

- Page 283 and 284: Packing the Printhead Figure 117 Sh

- Page 285 and 286: Unpacking the Printhead Unpacking t

- Page 287 and 288: Unpacking the Printhead Figure 127

- Page 289 and 290: Installing the Printhead Figure 130

- Page 291 and 292: Installing the Printhead 16. Refer

- Page 293 and 294: Chapter 4. Maintenance In general,

- Page 295 and 296: Preventive Maintenance Table 3 Tran

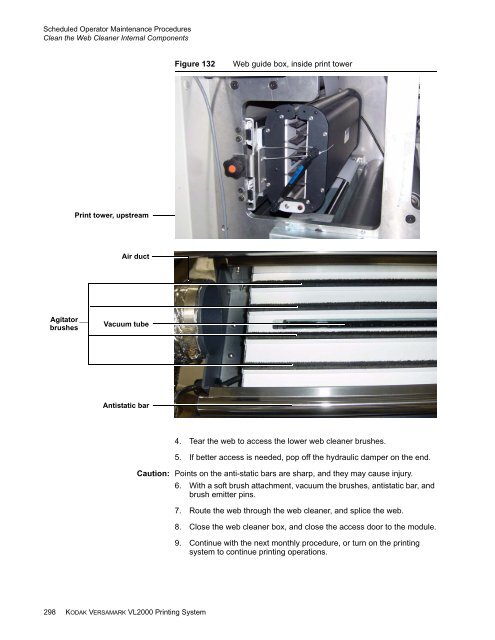

- Page 297: Scheduled Operator Maintenance Proc

- Page 301 and 302: Chapter 5. Troubleshooting The erro

- Page 303 and 304: Common Print Defects Action: Correc

- Page 305 and 306: Printing Problems Print Screen Stat

- Page 307 and 308: Glossary This appendix contains a g

- Page 309 and 310: Glossary cue sensor A sensor that d

- Page 311 and 312: Glossary 3. An architected host-to-

- Page 313 and 314: Glossary punch-perforation A proces

- Page 315 and 316: Glossary web break sensor A section

- Page 317 and 318: Index Emergency Stop button unwind

- Page 319 and 320: Index S Saving accounting informati

- Page 322: Eastman Kodak Company 3000 Research