PDFï¼7.7MB

PDFï¼7.7MB

PDFï¼7.7MB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

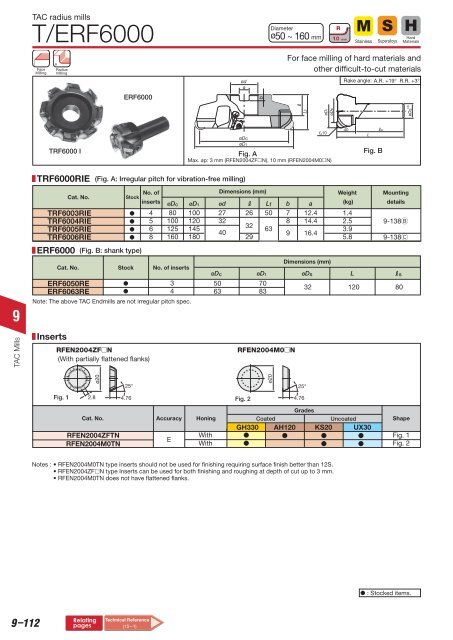

TAC radius mills<br />

T/ERF6000<br />

Diameter<br />

ø50 ~ 160 mm<br />

R<br />

10 mm<br />

Stainless<br />

Superalloys<br />

Hard<br />

Materials<br />

Face<br />

Milling<br />

R<br />

Radius<br />

Milling<br />

ød<br />

a<br />

For face milling of hard materials and<br />

other difficult-to-cut materials<br />

Rake angle: A.R. +19° R.R. +3°<br />

ERF6000<br />

Lf<br />

R<br />

øD1<br />

øDc<br />

øDs h6<br />

b<br />

TRF6000 I<br />

r ε10<br />

øDc<br />

øD1<br />

Fig. A<br />

Max. ap: 3 mm (RFEN2004ZFN), 10 mm (RFEN2004M0N)<br />

40<br />

L<br />

Rs<br />

Fig. B<br />

TRF6000RIE<br />

(Fig. A: Irregular pitch for vibration-free milling)<br />

9<br />

TRF6003RIE<br />

TRF6004RIE<br />

TRF6005RIE<br />

TRF6006RIE<br />

ERF6000<br />

Cat. No.<br />

ERF6050RE<br />

ERF6063RE<br />

<br />

<br />

<br />

<br />

<br />

<br />

(Fig. B: shank type)<br />

No. of<br />

Stock<br />

inserts<br />

Note: The above TAC Endmills are not irregular pitch spec.<br />

4<br />

5<br />

6<br />

8<br />

Cat. No. Stock No. of inserts<br />

øDc øD 1 ød R Lf b a<br />

80 100 27 26 50 7 12.4<br />

100 120 32<br />

8 14.4<br />

125 145<br />

32<br />

63<br />

40<br />

9 16.4<br />

160 180<br />

29<br />

3<br />

4<br />

øDc<br />

50<br />

63<br />

Dimensions (mm)<br />

Dimensions (mm)<br />

øD 1 øDs<br />

70<br />

32<br />

83<br />

Weight<br />

(kg)<br />

1.4<br />

2.5<br />

3.9<br />

5.8<br />

L<br />

120<br />

Mounting<br />

details<br />

9-138B<br />

9-138C<br />

Rs<br />

80<br />

TAC Mills<br />

Inserts<br />

RFEN2004ZFN<br />

(With partially flattened flanks)<br />

RFEN2004M0N<br />

ø20<br />

25° 25°<br />

ø20<br />

Fig. 1 2.8 4.76<br />

Fig. 2<br />

4.76<br />

Cat. No.<br />

RFEN2004ZFTN<br />

RFEN2004M0TN<br />

Grades<br />

Accuracy Honing Coated<br />

Uncoated<br />

Shape<br />

GH330 AH120 KS20 UX30<br />

With Fig. 1<br />

E<br />

With <br />

Fig. 2<br />

Notes : • RFEN2004M0TN type inserts should not be used for finishing requiring surface finish better than 12S.<br />

• RFEN2004ZFN type Inserts can be used for both finishing and roughing at depth of cut up to 3 mm.<br />

• RFEN2004M0TN does not have flattened flanks.<br />

: Stocked items.<br />

9–112<br />

<br />

<br />

Technical Reference<br />

(15-1)