PDFï¼7.7MB

PDFï¼7.7MB

PDFï¼7.7MB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

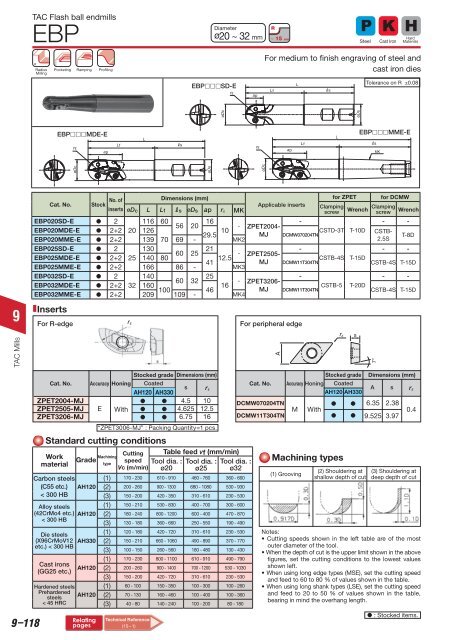

TAC Flash ball endmills<br />

EBP<br />

R<br />

Radius<br />

Milling<br />

Pocketing Ramping Profiling<br />

Diameter<br />

EBPSD-E<br />

ø20 ~ 32 mm<br />

rε<br />

ap<br />

R<br />

~ 15 mm<br />

Lf<br />

Rs<br />

Steel<br />

Cast Iron<br />

Hard<br />

Materials<br />

For medium to finish engraving of steel and<br />

cast iron dies<br />

Tolerance on R ±0.08<br />

rε<br />

ap<br />

Lf<br />

Rs<br />

øDc<br />

øDs<br />

øDc<br />

øDc<br />

øDs<br />

EBPMDE-E<br />

EBPMME-E<br />

rε<br />

ap<br />

Lf<br />

Rs<br />

9<br />

TAC Mills<br />

Cat. No.<br />

øDc L Lf Rs øDs ap r ε<br />

EBP020SD-E 2 116 60 16<br />

-<br />

- -<br />

56 20 - ZPET2004-<br />

EBP020MDE-E 2+2 20 126<br />

10<br />

CSTD-3T T-10D CSTB-<br />

29.5 MJ DCMW070204TN<br />

T-8D<br />

EBP020MME-E 2+2 139 70 69 - MK2<br />

2.5S<br />

EBP025SD-E 2 130<br />

60 25 21 25<br />

12.5 - ZPET2505- -<br />

- -<br />

EBP025MDE-E 2+2 140 80<br />

CSTB-4S T-15D<br />

41 MJ DCMW11T304TN CSTB-4S T-15D<br />

EBP025MME-E 2+2 166 86 - MK3<br />

EBP032SD-E 2 140<br />

60 32 25 -<br />

- -<br />

- ZPET3206-<br />

EBP032MDE-E 2+2 32 160 16<br />

CSTB-5 T-20D<br />

100 46 MJ DCMW11T304TN CSTB-4S T-15D<br />

EBP032MME-E 2+2 209 109 - MK4<br />

Inserts<br />

For R-edge<br />

No. of<br />

Stock<br />

inserts<br />

Dimensions (mm)<br />

MK<br />

Applicable inserts<br />

For peripheral edge<br />

A<br />

Clamping<br />

screw<br />

for ZPET<br />

r ε<br />

Wrench<br />

s<br />

for DCMW<br />

Clamping<br />

screw Wrench<br />

7°<br />

r ε<br />

10<br />

9–118<br />

Stocked grade Dimensions (mm)<br />

Cat. No. Accuracy Honing Coated<br />

AH120 AH330<br />

s r ε<br />

ZPET2004-MJ<br />

ZPET2505-MJ<br />

ZPET3206-MJ<br />

E With<br />

<br />

<br />

<br />

<br />

<br />

<br />

4.5<br />

4.625<br />

6.75<br />

12.5<br />

16<br />

Standard cutting conditions<br />

Work<br />

material<br />

Carbon steels<br />

(C55 etc.)<br />

< 300 HB<br />

Alloy steels<br />

(42CrMo4 etc.)<br />

< 300 HB<br />

Die steels<br />

(X96CrMoV12<br />

etc.) < 300 HB<br />

Cast irons<br />

(GG25 etc.)<br />

Hardened steels<br />

Prehardened<br />

steels<br />

< 45 HRC<br />

Grade<br />

AH120<br />

AH120<br />

AH330<br />

AH120<br />

AH120<br />

<br />

<br />

“ZPET3006-MJ” : Packing Quantity=1 pcs.<br />

Cutting Table feed vf (mm/min)<br />

type<br />

speed Tool dia. : Tool dia. : Tool dia. :<br />

Vc (m/min) ø20 ø25 ø32<br />

(1) 170 - 230 610 - 910 460 - 760 360 - 660<br />

(2) 200 - 260 900 - 1300 680 - 1080 530 - 930<br />

Machining<br />

(3) 150 - 200 420 - 350 310 - 610 230 - 530<br />

(1) 150 - 210 530 - 830 400 - 700 300 - 600<br />

(2) 180 - 240 800 - 1200 600 - 400 470 - 870<br />

(3) 130 - 180 360 - 660 250 - 550 190 - 490<br />

(1) 120 - 180 420 - 720 310 - 610 230 - 530<br />

(2) 150 - 210 660 - 1060 490 - 890 370 - 770<br />

(3) 100 - 150 260 - 560 180 - 480 130 - 430<br />

(1) 170 - 230 800 - 1100 610 - 910 490 - 790<br />

(2) 200 - 260 900 - 1400 700 - 1200 530 - 1030<br />

(3) 150 - 200 420 - 720 310 - 610 230 - 530<br />

(1) 60 - 100 150 - 350 100 - 300 100 - 260<br />

(2) 70 - 130 160 - 460 100 - 400 100 - 360<br />

(3) 40 - 80 140 - 240 100 - 200 80 - 180<br />

Technical Reference<br />

(15-1)<br />

Cat. No.<br />

DCMW070204TN<br />

DCMW11T304TN<br />

Stocked grade<br />

Accuracy Honing Coated<br />

AH120 AH330<br />

M<br />

<br />

<br />

Machining types<br />

(1) Grooving<br />

With<br />

<br />

<br />

(2) Shouldering at<br />

shallow depth of cut<br />

Dimensions (mm)<br />

A<br />

6.35<br />

9.525<br />

s<br />

r ε<br />

2.38<br />

3.97 0.4<br />

(3) Shouldering at<br />

deep depth of cut<br />

Notes:<br />

• Cutting speeds shown in the left table are of the most<br />

outer diameter of the tool.<br />

• When the depth of cut is the upper limit shown in the above<br />

figures, set the cutting conditions to the lowest values<br />

shown left.<br />

• When using long edge types (MSE), set the cutting speed<br />

and feed to 60 to 80 % of values shown in the table.<br />

• When using long shank types (LSE), set the cutting speed<br />

and feed to 20 to 50 % of values shown in the table,<br />

bearing in mind the overhang length.<br />

: Stocked items.