PDFï¼7.7MB

PDFï¼7.7MB

PDFï¼7.7MB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

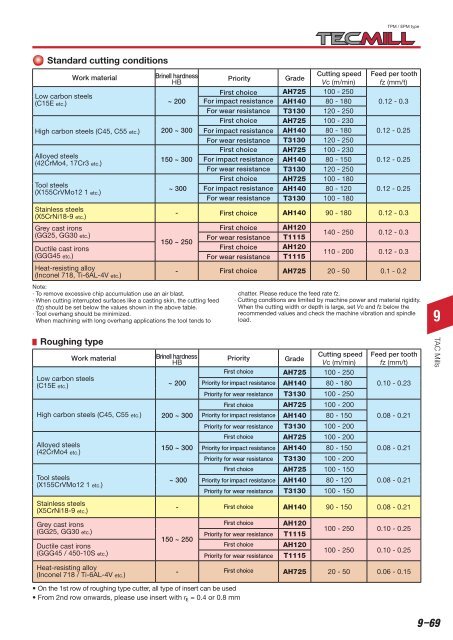

TPM / EPM type<br />

Standard cutting conditions<br />

Work material Brinell hardness Cutting speed Feed per tooth<br />

Priority Grade<br />

HB Vc (m/min) fz (mm/t)<br />

First choice AH725 100 - 250<br />

Low carbon steels<br />

(C15E etc.)<br />

~ 200 For impact resistance AH140 80 - 180 0.12 - 0.3<br />

For wear resistance T3130 120 - 250<br />

First choice AH725 100 - 230<br />

High carbon steels (C45, C55 etc.) 200 ~ 300 For impact resistance AH140 80 - 180 0.12 - 0.25<br />

For wear resistance T3130 120 - 250<br />

First choice AH725 100 - 230<br />

Alloyed steels<br />

150 ~ 300 For impact resistance AH140 80 - 150<br />

(42CrMo4, 17Cr3 etc.)<br />

For wear resistance T3130 120 - 250<br />

0.12 - 0.25<br />

First choice AH725 100 - 180<br />

Tool steels<br />

~ 300 For impact resistance AH140 80 - 120<br />

(X155CrVMo12 1 etc.)<br />

For wear resistance T3130 100 - 180<br />

0.12 - 0.25<br />

Stainless steels<br />

(X5CrNi18-9 etc.)<br />

- First choice AH140 90 - 180 0.12 - 0.3<br />

Grey cast irons<br />

(GG25, GG30 etc.)<br />

Ductile cast irons<br />

(GGG45 etc.)<br />

Heat-resisting alloy<br />

(Inconel 718, Ti-6AL-4V etc.)<br />

150 ~ 250<br />

Note:<br />

· To remove excessive chip accumulation use an air blast.<br />

· When cutting interrupted surfaces like a casting skin, the cutting feed<br />

(fz) should be set below the values shown in the above table.<br />

· Tool overhang should be minimized.<br />

When machining with long overhang applications the tool tends to<br />

Roughing type<br />

First choice<br />

For wear resistance<br />

First choice<br />

For wear resistance<br />

AH120<br />

T1115<br />

AH120<br />

T1115<br />

140 - 250 0.12 - 0.3<br />

110 - 200 0.12 - 0.3<br />

- First choice AH725 20 - 50 0.1 - 0.2<br />

chatter. Please reduce the feed rate fz.<br />

· Cutting conditions are limited by machine power and material rigidity.<br />

When the cutting width or depth is large, set Vc and fz below the<br />

recommended values and check the machine vibration and spindle<br />

load.<br />

Work material Brinell hardness Cutting speed Feed per tooth<br />

Priority Grade<br />

HB Vc (m/min) fz (mm/t)<br />

First choice AH725 100 - 250<br />

Low carbon steels<br />

(C15E ~ 200 Priority for impact resistance<br />

etc.)<br />

AH140 80 - 180 0.10 - 0.23<br />

Priority for wear resistance T3130 100 - 250<br />

First choice AH725 100 - 200<br />

High carbon steels (C45, C55 etc.) 200 ~ 300 Priority for impact resistance AH140 80 - 150 0.08 - 0.21<br />

Priority for wear resistance T3130 100 - 200<br />

First choice AH725 100 - 200<br />

Alloyed steels<br />

150 ~ 300 Priority for impact resistance AH140 80 - 150 0.08 - 0.21<br />

(42CrMo4 etc.)<br />

Priority for wear resistance T3130 100 - 200<br />

First choice AH725 100 - 150<br />

Tool steels<br />

~ 300 Priority for impact resistance AH140 80 - 120 0.08 - 0.21<br />

(X155CrVMo12 1 etc.)<br />

Priority for wear resistance T3130 100 - 150<br />

Stainless steels<br />

(X5CrNi18-9 etc.)<br />

- First choice AH140 90 - 150 0.08 - 0.21<br />

Grey cast irons<br />

First choice AH120<br />

(GG25, GG30 etc.)<br />

100 - 250 0.10 - 0.25<br />

Priority for wear resistance T1115<br />

150 ~ 250<br />

Ductile cast irons<br />

First choice AH120<br />

(GGG45 / 450-10S etc.)<br />

100 - 250 0.10 - 0.25<br />

Priority for wear resistance T1115<br />

Heat-resisting alloy<br />

(Inconel 718 / Ti-6AL-4V etc.)<br />

- First choice AH725 20 - 50 0.06 - 0.15<br />

9<br />

TAC Mills<br />

• On the 1st row of roughing type cutter, all type of insert can be used<br />

• From 2nd row onwards, please use insert with rε = 0.4 or 0.8 mm<br />

9–69