PDFï¼7.7MB

PDFï¼7.7MB

PDFï¼7.7MB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

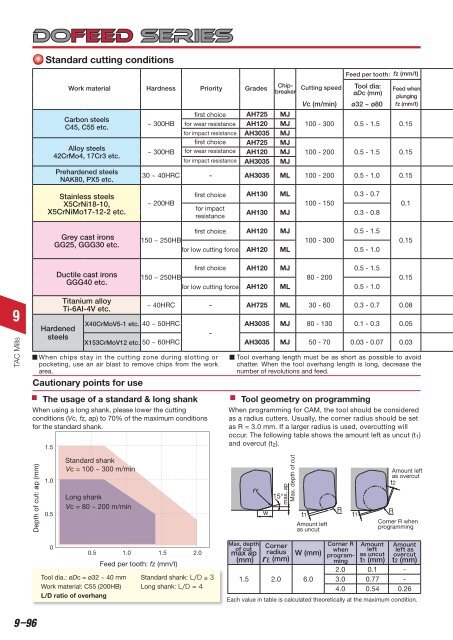

Standard cutting conditions<br />

Work material Hardness Priority Grades<br />

Carbon steels<br />

C45, C55 etc.<br />

Alloy steels<br />

42CrMo4, 17Cr3 etc.<br />

Prehardened steels<br />

NAK80, PX5 etc.<br />

~ 300HB<br />

~ 300HB<br />

first choice<br />

for wear resistance<br />

for impact resistance<br />

first choice<br />

for wear resistance<br />

for impact resistance<br />

AH725<br />

AH120<br />

AH3035<br />

AH725<br />

AH120<br />

AH3035<br />

Chipbreaker<br />

MJ<br />

MJ<br />

MJ<br />

MJ<br />

MJ<br />

MJ<br />

Cutting speed<br />

Vc (m/min)<br />

Feed per tooth: fz (mm/t)<br />

Tool dia:<br />

øDc (mm)<br />

ø32 ~ ø80<br />

Feed when<br />

plunging<br />

fz (mm/t)<br />

100 - 300 0.5 - 1.5 0.15<br />

100 - 200 0.5 - 1.5 0.15<br />

30 ~ 40HRC - AH3035 ML 100 - 200 0.5 - 1.0 0.15<br />

Stainless steels<br />

X5CrNi18-10,<br />

X5CrNiMo17-12-2 etc.<br />

~ 200HB<br />

first choice<br />

for impact<br />

resistance<br />

AH130 ML<br />

0.3 - 0.7<br />

100 - 150<br />

AH130 MJ 0.3 - 0.8<br />

0.1<br />

Grey cast irons<br />

GG25, GGG30 etc.<br />

first choice<br />

150 ~ 250HB<br />

for low cutting force<br />

AH120 MJ<br />

0.5 - 1.5<br />

100 - 300<br />

AH120 ML 0.5 - 1.0<br />

0.15<br />

Ductile cast irons<br />

GGG40 etc.<br />

first choice<br />

150 ~ 250HB<br />

for low cutting force<br />

AH120 MJ<br />

0.5 - 1.5<br />

80 - 200<br />

AH120 ML 0.5 - 1.0<br />

0.15<br />

9<br />

TAC Mills<br />

Hardened<br />

steels<br />

1.5<br />

Titanium alloy<br />

Ti-6AI-4V etc.<br />

~ 40HRC - AH725 ML 30 - 60 0.3 - 0.7 0.08<br />

X40CrMoV5-1 etc. 40 ~ 50HRC<br />

AH3035 MJ 80 - 130 0.1 - 0.3 0.05<br />

-<br />

X153CrMoV12 etc. 50 ~ 60HRC AH3035 MJ 50 - 70 0.03 - 0.07 0.03<br />

When chips stay in the cutting zone during slotting or<br />

pocketing, use an air blast to remove chips from the work<br />

area.<br />

Cautionary points for use<br />

The usage of a standard & long shank<br />

When using a long shank, please lower the cutting<br />

conditions (Vc, fz, ap) to 70% of the maximum conditions<br />

for the standard shank.<br />

Tool overhang length must be as short as possible to avoid<br />

chatter. When the tool overhang length is long, decrease the<br />

number of revolutions and feed.<br />

Tool geometry on programming<br />

When programming for CAM, the tool should be considered<br />

as a radius cutters. Usually, the corner radius should be set<br />

as R = 3.0 mm. If a larger radius is used, overcutting will<br />

occur. The following table shows the amount left as uncut (t 1 )<br />

and overcut (t 2 ).<br />

Depth of cut:ap (mm)<br />

1.0<br />

0.5<br />

Standard shank<br />

Vc = 100 ~ 300 m/min<br />

Long shank<br />

Vc = 80 ~ 200 m/min<br />

rε<br />

w<br />

15°<br />

max. ap<br />

Max. depth of cut<br />

t1 t1<br />

Amount left<br />

as uncut<br />

t2<br />

R R<br />

Amount left<br />

as overcut<br />

Corner R when<br />

programming<br />

0<br />

Tool dia.: øDc = ø32 ~ 40 mm<br />

Work material: C55 (200HB)<br />

L/D ratio of overhang<br />

0.5 1.0 1.5 2.0<br />

Feed per tooth: fz (mm/t)<br />

Standard shank<br />

Long shank<br />

<br />

<br />

max ap<br />

(mm)<br />

<br />

<br />

rε (mm)<br />

W (mm)<br />

1.5 2.0 6.0<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

t1 (mm) t2 (mm)<br />

2.0 0.1 -<br />

3.0 0.77 -<br />

4.0 0.54 0.26<br />

Each value in table is calculated theoretically at the maximum condition.<br />

9–96