PDFï¼7.7MB

PDFï¼7.7MB

PDFï¼7.7MB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

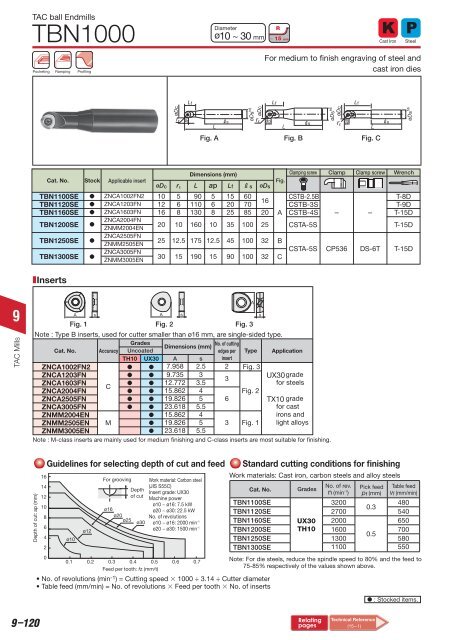

TAC ball Endmills<br />

TBN1000<br />

Pocketing Ramping Profiling<br />

Diameter<br />

ø10 ~ 30 mm<br />

R<br />

~ 15 mm<br />

Cast Iron<br />

Steel<br />

For medium to finish engraving of steel and<br />

cast iron dies<br />

Lf<br />

Lf<br />

Lf<br />

øDc<br />

r ε<br />

ap<br />

L<br />

Rs<br />

øDs h6<br />

øDc<br />

r ε<br />

ap<br />

L<br />

Rs<br />

øDs h6<br />

øDc<br />

rε<br />

ap<br />

L<br />

Rs<br />

øDs h6<br />

Fig. A Fig. B Fig. C<br />

Cat. No.<br />

Stock<br />

Applicable insert<br />

Dimensions (mm)<br />

øDc r ε L ap Lf Rs øDs<br />

Fig.<br />

Clamping screw<br />

Clamp Clamp screw Wrench<br />

TBN1100SE<br />

TBN1120SE<br />

TBN1160SE<br />

TBN1200SE<br />

TBN1250SE<br />

TBN1300SE<br />

<br />

<br />

<br />

<br />

<br />

<br />

ZNCA1002FN2<br />

ZNCA1203FN<br />

ZNCA1603FN<br />

ZNCA2004FN<br />

ZNMM2004EN<br />

ZNCA2505FN<br />

ZNMM2505EN<br />

ZNCA3005FN<br />

ZNMM3005EN<br />

10 5 90 5 15 60<br />

16<br />

12 6 110 6 20 70<br />

16 8 130 8 25 85 20<br />

20 10 160 10 35 100 25<br />

25 12.5 175 12.5 45 100 32<br />

30 15 190 15 90 100 32<br />

A<br />

B<br />

C<br />

CSTB-2.5B<br />

CSTB-3S<br />

CSTB-4S<br />

CSTA-5S<br />

CSTA-5S<br />

-<br />

CP536<br />

-<br />

DS-6T<br />

T-8D<br />

T-9D<br />

T-15D<br />

T-15D<br />

T-15D<br />

Inserts<br />

9<br />

TAC Mills<br />

A s A s<br />

Fig. 1 Fig. 2 Fig. 3<br />

Note : Type B inserts, used for cutter smaller than ø16 mm, are single-sided type.<br />

Grades<br />

No. of cutting<br />

Dimensions (mm)<br />

Cat. No.<br />

Accuracy Uncoated<br />

edges per Type Application<br />

TH10 UX30 A s<br />

insert<br />

ZNCA1002FN2<br />

7.958 2.5 2 Fig. 3<br />

ZNCA1203FN<br />

9.735 3<br />

3<br />

UX30grade<br />

ZNCA1603FN<br />

12.772 3.5<br />

for steels<br />

C<br />

ZNCA2004FN<br />

15.862 4<br />

Fig. 2<br />

ZNCA2505FN<br />

ZNCA3005FN<br />

ZNMM2004EN<br />

<br />

<br />

<br />

<br />

<br />

19.826<br />

23.618<br />

15.862<br />

5<br />

5.5<br />

4<br />

6<br />

TX10 grade<br />

for cast<br />

irons and<br />

ZNMM2505EN<br />

ZNMM3005EN<br />

M<br />

<br />

<br />

19.826<br />

23.618<br />

5<br />

5.5<br />

3 Fig. 1 light alloys<br />

Note : M-class inserts are mainly used for medium finishing and C-class inserts are most suitable for finishing.<br />

A<br />

s<br />

Depth of cut: ap (mm)<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

Guidelines for selecting depth of cut and feed<br />

ø10<br />

ø12<br />

For grooving Work material: Carbon steel<br />

(JIS S55C)<br />

Depth<br />

Insert grade: UX30<br />

of cut<br />

Machine power<br />

ø10 ~ ø16: 7.5 kW<br />

TBN1100SE<br />

ø16<br />

ø20 ~ ø30: 22.5 kW<br />

ø20 No. of revolutions<br />

ø25 ø30<br />

ø10 ~ ø16: 2000 min -1<br />

ø20 ~ ø30: 1500 min -1<br />

Standard cutting conditions for finishing<br />

Work materials: Cast iron, carbon steels and alloy steels<br />

Cat. No. Grades<br />

3200<br />

480<br />

0.3<br />

TBN1120SE 2700 540<br />

TBN1160SE UX30 2000<br />

650<br />

TBN1200SE TH10 1600 700<br />

0.5<br />

TBN1250SE 1300 580<br />

TBN1300SE 1100 550<br />

0<br />

0.1 0.2 0.3 0.4 0.5 0.6 0.7 Note: For die steels, reduce the spindle speed to 80% and the feed to<br />

75-85% respectively of the values shown above.<br />

Feed per tooth: fz (mm/t)<br />

• No. of revolutions (min -1 ) = Cutting speed 1000 ÷ 3.14 ÷ Cutter diameter<br />

• Table feed (mm/min) = No. of revolutions Feed per tooth No. of inserts<br />

No. of rev.<br />

n (min -1 )<br />

Pick feed<br />

p f (mm)<br />

Table feed<br />

v f (mm/min)<br />

: Stocked items.<br />

9–120<br />

<br />

<br />

Technical Reference<br />

(15-1)