PDFï¼7.7MB

PDFï¼7.7MB

PDFï¼7.7MB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

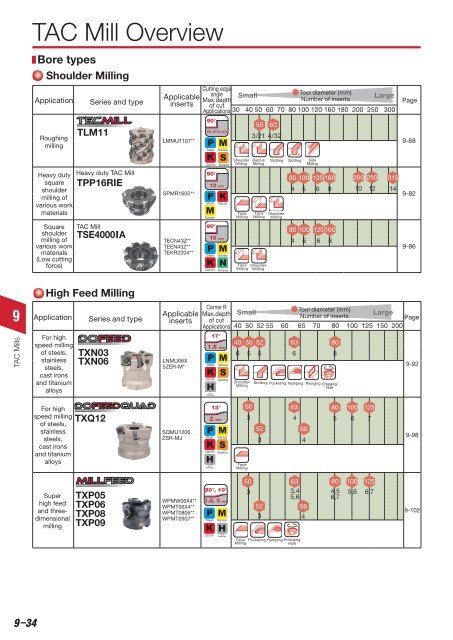

TAC Mill Overview<br />

Bore types<br />

Shoulder Milling<br />

Application<br />

Roughing<br />

milling<br />

Heavy duty<br />

square<br />

shoulder<br />

milling of<br />

various work<br />

materials<br />

Square<br />

shoulder<br />

milling of<br />

various work<br />

materials<br />

(Low cutting<br />

force)<br />

Series and type<br />

TUNGALOY<br />

TLM11<br />

Heavy duty TAC Mill<br />

TPP16RIE<br />

TAC Mill<br />

TSE4000A<br />

Applicable<br />

inserts<br />

LMMU1107**<br />

SPMR1605**<br />

TECN43Z**<br />

TEEN43Z**<br />

TEKR2204**<br />

Cutting edge<br />

angle<br />

Max.depth<br />

Tool diameter (mm)<br />

Small<br />

Large<br />

Number of inserts<br />

of cut<br />

Applications 30 40 50 60 70 80 100 120 160 180 200 250 300<br />

90°<br />

50 63<br />

59, 67.4 mm<br />

3/21 4/32<br />

Steel<br />

Cast Iron<br />

90°<br />

12 mm<br />

Steel<br />

Stainless<br />

90°<br />

10 mm<br />

Steel<br />

Stainless<br />

Superalloys<br />

Cast Iron<br />

Stainless<br />

Cast Iron Non-ferrous<br />

Shoulder<br />

Milling<br />

Face<br />

Milling<br />

R<br />

Radius<br />

Milling<br />

Face<br />

Milling<br />

Face<br />

Milling Shoulder<br />

Milling<br />

R<br />

Slotting Slotting Side<br />

Milling<br />

Shoulder<br />

Milling<br />

R<br />

80 100 125 160<br />

4 5 6 8<br />

80 100 125 160<br />

4 6 6 8<br />

200 250<br />

10 12<br />

315<br />

14<br />

Page<br />

9-68<br />

9-82<br />

9-86<br />

9<br />

TAC Mills<br />

High Feed Milling<br />

Application<br />

For high<br />

speed milling<br />

of steels,<br />

stainless<br />

steels,<br />

cast irons<br />

and titanium<br />

alloys<br />

Series and type<br />

TXN03<br />

TXN06<br />

Applicable<br />

inserts<br />

LNMU06X<br />

5ZER-M*<br />

Corner R<br />

Max.depth<br />

of cut<br />

Applications<br />

17°<br />

1.5 mm<br />

Steel<br />

Cast Iron Superalloys<br />

Hard<br />

Materials<br />

Stainless<br />

Tool diameter (mm)<br />

Small<br />

Large<br />

Number of inserts<br />

Page<br />

40 50 52 55 60 65 70 80 100 125 150 200<br />

40 50 52<br />

6 5 5<br />

Shoulder<br />

Milling<br />

Slotting<br />

63<br />

6<br />

80<br />

8<br />

Pocketing Ramping Plunging Enlarging<br />

Hole<br />

9-92<br />

For high<br />

speed milling<br />

of steels,<br />

stainless<br />

steels,<br />

cast irons<br />

and titanium<br />

alloys<br />

TXQ12<br />

SQMU1206<br />

ZSR-MJ<br />

13°<br />

2 mm<br />

Steel<br />

Cast Iron Superalloys<br />

Hard<br />

Materials<br />

Stainless<br />

50<br />

3<br />

Face<br />

Milling<br />

52<br />

3<br />

63<br />

4<br />

66<br />

4<br />

80<br />

5<br />

100<br />

6<br />

125<br />

7<br />

9-98<br />

Super<br />

high feed<br />

and threedimensional<br />

milling<br />

TXP05<br />

TXP06<br />

TXP08<br />

TXP09<br />

WPMW06X4**<br />

WPMT06X4**<br />

WPMT0806**<br />

WPMT0907**<br />

20°, 10°<br />

1.5, 3 mm<br />

Steel<br />

Stainless<br />

50<br />

3<br />

52<br />

3<br />

63<br />

3,4<br />

5,6<br />

66<br />

4<br />

80<br />

4,5<br />

6,7<br />

100<br />

5,6<br />

125<br />

6,7<br />

9-102<br />

Cast Iron<br />

Hard<br />

Materials<br />

Face<br />

Milling<br />

Pocketing Ramping Enlarging<br />

Hole<br />

9–34