PDFï¼7.7MB

PDFï¼7.7MB

PDFï¼7.7MB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

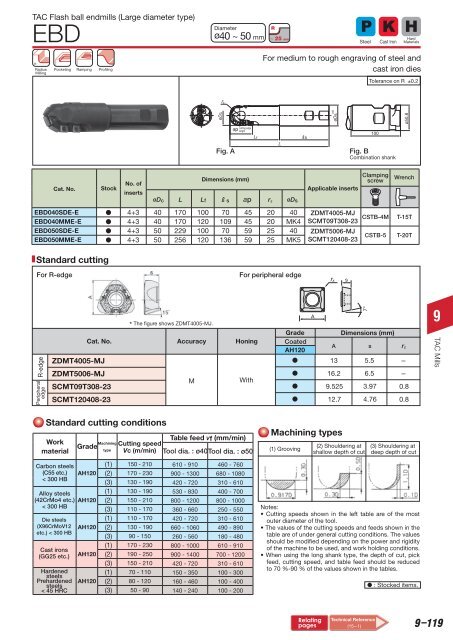

TAC Flash ball endmills (Large diameter type)<br />

EBD<br />

R<br />

Radius<br />

Milling<br />

Pocketing Ramping Profiling<br />

Diameter<br />

ø40 ~ 50 mm<br />

R<br />

~ 25 mm<br />

Steel<br />

Cast Iron<br />

Hard<br />

Materials<br />

For medium to rough engraving of steel and<br />

cast iron dies<br />

Tolerance on R ±0.2<br />

r ε<br />

øDc<br />

øDs h6<br />

ø50.8<br />

Fig. A<br />

ap<br />

cutting edge<br />

length<br />

L f<br />

L<br />

Rs<br />

100<br />

Fig. B<br />

Combination shank<br />

Cat. No.<br />

Stock<br />

No. of<br />

inserts<br />

Dimensions (mm)<br />

øDc L Lf Rs ap r ε øDs<br />

Applicable inserts<br />

Clamping<br />

screw<br />

Wrench<br />

EBD040SDE-E 4+3 40 170 100 70 45 20 40 ZDMT4005-MJ<br />

EBD040MME-E 4+3 40 170 120 109 45 20 MK4 SCMT09T308-23 CSTB-4M T-15T<br />

EBD050SDE-E 4+3 50 229 100 70 59 25 40 ZDMT5006-MJ<br />

CSTB-5 T-20T<br />

EBD050MME-E 4+3 50 256 120 136 59 25 MK5 SCMT120408-23<br />

Standard cutting<br />

For R-edge<br />

For peripheral edge<br />

r ε<br />

s<br />

Peripheral<br />

edge R-edge<br />

Cat. No.<br />

ZDMT4005-MJ<br />

ZDMT5006-MJ<br />

SCMT09T308-23<br />

SCMT120408-23<br />

* The figure shows ZDMT4005-MJ.<br />

Accuracy<br />

M<br />

Honing<br />

With<br />

Grade<br />

Coated<br />

AH120<br />

<br />

<br />

<br />

<br />

A<br />

7°<br />

Dimensions (mm)<br />

A<br />

s<br />

13 5.5<br />

16.2 6.5<br />

9.525 3.97<br />

12.7 4.76<br />

r ε<br />

-<br />

-<br />

0.8<br />

0.8<br />

9<br />

TAC Mills<br />

Standard cutting conditions<br />

Work<br />

material<br />

Grade<br />

Machining<br />

type<br />

Cutting speed<br />

Vc (m/min)<br />

Table feed vf (mm/min)<br />

Tool dia. : ø40Tool dia. : ø50<br />

Machining types<br />

(1) Grooving<br />

(2) Shouldering at<br />

shallow depth of cut<br />

(3) Shouldering at<br />

deep depth of cut<br />

Carbon steels<br />

(C55 etc.)<br />

< 300 HB<br />

Alloy steels<br />

(42CrMo4 etc.)<br />

< 300 HB<br />

Die steels<br />

(X96CrMoV12<br />

etc.) < 300 HB<br />

Cast irons<br />

(GG25 etc.)<br />

Hardened<br />

steels<br />

Prehardened<br />

steels<br />

< 45 HRC<br />

AH120<br />

AH120<br />

AH120<br />

AH120<br />

AH120<br />

(1) 150 - 210 610 - 910 460 - 760<br />

(2) 170 - 230 900 - 1300 680 - 1080<br />

(3) 130 - 190 420 - 720 310 - 610<br />

(1) 130 - 190 530 - 830 400 - 700<br />

(2) 150 - 210 800 - 1200 800 - 1000<br />

(3) 110 - 170 360 - 660 250 - 550<br />

(1) 110 - 170 420 - 720 310 - 610<br />

(2) 130 - 190 660 - 1060 490 - 890<br />

(3) 90 - 150 260 - 560 180 - 480<br />

(1) 170 - 230 800 - 1000 610 - 910<br />

(2) 190 - 250 900 - 1400 700 - 1200<br />

(3) 150 - 210 420 - 720 310 - 610<br />

(1) 70 - 110 150 - 350 100 - 300<br />

(2) 80 - 120 160 - 460 100 - 400<br />

(3) 50 - 90 140 - 240 100 - 200<br />

Notes:<br />

• Cutting speeds shown in the left table are of the most<br />

outer diameter of the tool.<br />

• The values of the cutting speeds and feeds shown in the<br />

table are of under general cutting conditions. The values<br />

should be modified depending on the power and rigidity<br />

of the machine to be used, and work holding conditions.<br />

• When using the long shank type, the depth of cut, pick<br />

feed, cutting speed, and table feed should be reduced<br />

to 70 %-90 % of the values shown in the tables.<br />

: Stocked items.<br />

<br />

<br />

Technical Reference<br />

(15-1)<br />

9–119