PDFï¼7.7MB

PDFï¼7.7MB

PDFï¼7.7MB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

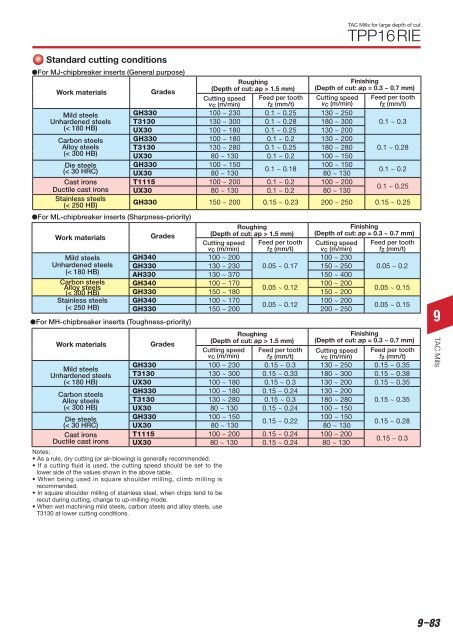

TAC Mills for large depth of cut<br />

TPP16RIE<br />

Standard cutting conditions<br />

For MJ-chipbreaker inserts (General purpose)<br />

Work materials<br />

Grades<br />

Roughing<br />

Finishing<br />

(Depth of cut: ap > 1.5 mm) (Depth of cut: ap = 0.3 ~ 0.7 mm)<br />

Cutting speed Feed per tooth Cutting speed Feed per tooth<br />

vc (m/min) fz (mm/t) vc (m/min) fz (mm/t)<br />

Mild steels<br />

GH330 100 ~ 230 0.1 ~ 0.25 130 ~ 250<br />

Unhardened steels T3130 130 ~ 300 0.1 ~ 0.28 180 ~ 300 0.1 ~ 0.3<br />

(< 180 HB)<br />

UX30 100 ~ 180 0.1 ~ 0.25 130 ~ 200<br />

Carbon steels GH330 100 ~ 180 0.1 ~ 0.2 130 ~ 200<br />

Alloy steels T3130 130 ~ 280 0.1 ~ 0.25 180 ~ 280 0.1 ~ 0.28<br />

(< 300 HB)<br />

UX30 80 ~ 130 0.1 ~ 0.2 100 ~ 150<br />

Die steels<br />

GH330 100 ~ 150<br />

100 ~ 150<br />

(< 30 HRC)<br />

0.1 ~ 0.18<br />

UX30 80 ~ 130 80 ~ 130<br />

0.1 ~ 0.2<br />

Cast irons<br />

T1115 100 ~ 200 0.1 ~ 0.2 100 ~ 200<br />

Ductile cast irons UX30 80 ~ 130 0.1 ~ 0.2 80 ~ 130<br />

0.1 ~ 0.25<br />

Stainless steels<br />

(< 250 HB)<br />

GH330 150 ~ 200 0.15 ~ 0.23 200 ~ 250 0.15 ~ 0.25<br />

For ML-chipbreaker inserts (Sharpness-priority)<br />

Work materials<br />

Mild steels<br />

Unhardened steels<br />

(< 180 HB)<br />

Carbon steels<br />

Alloy steels<br />

(< 300 HB)<br />

Stainless steels<br />

(< 250 HB)<br />

For MH-chipbreaker inserts (Toughness-priority)<br />

Work materials<br />

Mild steels<br />

Unhardened steels<br />

(< 180 HB)<br />

Carbon steels<br />

Alloy steels<br />

(< 300 HB)<br />

Die steels<br />

(< 30 HRC)<br />

Cast irons<br />

Ductile cast irons<br />

Notes:<br />

• As a rule, dry cutting (or air-blowing) is generally recommended.<br />

• If a cutting fluid is used, the cutting speed should be set to the<br />

lower side of the values shown in the above table.<br />

• When being used in square shoulder milling, climb milling is<br />

recommended.<br />

• In square shoulder milling of stainless steel, when chips tend to be<br />

recut during cutting, change to up-milling mode.<br />

• When wet machining mild steels, carbon steels and alloy steels, use<br />

T3130 at lower cutting conditions.<br />

Roughing<br />

Grades<br />

(Depth of cut: ap > 1.5 mm)<br />

Cutting speed Feed per tooth<br />

vc (m/min) fz (mm/t)<br />

Cutting speed<br />

vc (m/min)<br />

GH340 100 ~ 200<br />

100 ~ 230<br />

GH330 130 ~ 230 0.05 ~ 0.17 150 ~ 250<br />

AH330 130 ~ 370 150 ~ 400<br />

GH340 100 ~ 170<br />

100 ~ 200<br />

0.05 ~ 0.12<br />

GH330 150 ~ 180 150 ~ 200<br />

GH340 100 ~ 170<br />

100 ~ 200<br />

0.05 ~ 0.12<br />

GH330 150 ~ 200 200 ~ 250<br />

Grades<br />

Roughing<br />

(Depth of cut: ap > 1.5 mm)<br />

Finishing<br />

(Depth of cut: ap = 0.3 ~ 0.7 mm)<br />

Feed per tooth<br />

fz (mm/t)<br />

0.05 ~ 0.2<br />

0.05 ~ 0.15<br />

0.05 ~ 0.15<br />

Finishing<br />

(Depth of cut: ap = 0.3 ~ 0.7 mm)<br />

Cutting speed Feed per tooth Cutting speed Feed per tooth<br />

vc (m/min) fz (mm/t) vc (m/min) fz (mm/t)<br />

GH330 100 ~ 230 0.15 ~ 0.3 130 ~ 250 0.15 ~ 0.35<br />

T3130 130 ~ 300 0.15 ~ 0.33 180 ~ 300 0.15 ~ 0.38<br />

UX30 100 ~ 180 0.15 ~ 0.3 130 ~ 200 0.15 ~ 0.35<br />

GH330 100 ~ 180 0.15 ~ 0.24 130 ~ 200<br />

T3130 130 ~ 280 0.15 ~ 0.3 180 ~ 280 0.15 ~ 0.35<br />

UX30 80 ~ 130 0.15 ~ 0.24 100 ~ 150<br />

GH330 100 ~ 150<br />

100 ~ 150<br />

0.15 ~ 0.22<br />

UX30 80 ~ 130 80 ~ 130<br />

0.15 ~ 0.28<br />

T1115 100 ~ 200 0.15 ~ 0.24 100 ~ 200<br />

UX30 80 ~ 130 0.15 ~ 0.24 80 ~ 130<br />

0.15 ~ 0.3<br />

9<br />

TAC Mills<br />

9–83