- Page 1 and 2: R Lf ap 6.4mm Chapter Composition o

- Page 3 and 4: Designation System for TAC Mills TA

- Page 5 and 6: Designation System for TAC Milling

- Page 7 and 8: Selection Guide for TAC mills Face

- Page 9 and 10: Selection Guide for TAC mills Face

- Page 11 and 12: Selection Guide for TAC mills Face

- Page 13 and 14: Selection Guide for TAC mills Squar

- Page 15 and 16: Selection Guide for TAC mills Squar

- Page 17 and 18: Selection Guide for TAC mills Selec

- Page 19 and 20: TUNGALOY Selection 9 TAC Mills Char

- Page 21 and 22: Basic Selection for TAC Mills Face

- Page 23: Basic Selection for TAC Mills Face

- Page 27 and 28: Basic Selection for TAC Mills Shoul

- Page 29 and 30: Basic Selection for TAC Mills High

- Page 31 and 32: Basic Selection for TAC Mills Die E

- Page 33 and 34: TAC Mill Overview Bore types Face M

- Page 35 and 36: TAC Mill Overview Bore types Should

- Page 37 and 38: TAC Mill Overview Shank types Face

- Page 39 and 40: TAC Mill Overview Shank types High

- Page 41 and 42: TEN / EEN type Diameter ø32 ~ 160

- Page 43 and 44: TAN type Diameter ø63 ~ 315 mm 45

- Page 45 and 46: T/EAW13 Diameter ø50 ~ 160 mm 45°

- Page 47 and 48: T/EAW13 9 TAC Mills Standard cuttin

- Page 49 and 50: Lightning Mills TME4400 /B Face Mil

- Page 51 and 52: 15˚ 15˚ TAC Mills for large depth

- Page 53 and 54: TAC Mills TGP4100RBAE Standard cutt

- Page 55 and 56: All PCD-tipped TAC Mills for high f

- Page 57 and 58: TPQ / EPQ type JIS Diameter ø25 ~

- Page 59 and 60: TPO / EPO07 Diameter ø12 ~ 50mm St

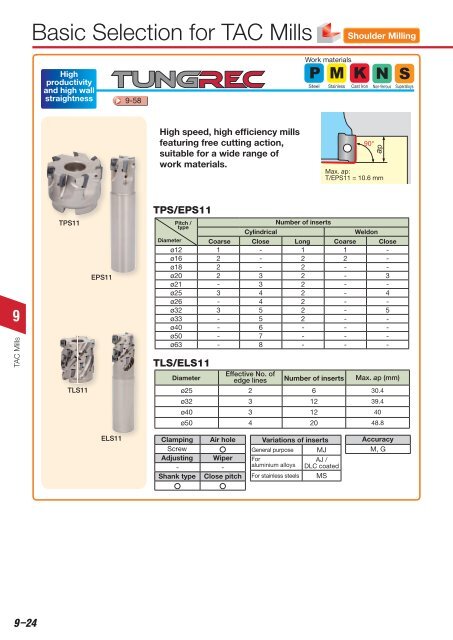

- Page 61 and 62: TPS / EPS11 Diameter ø12~63 mm Ste

- Page 63 and 64: TPS / EPS11 Replacement Parts TPS /

- Page 65 and 66: TPO / EPO18 Diameter ø25~160 mm St

- Page 67 and 68: Machining modes Shoulder milling Sl

- Page 69 and 70: TPM / EPM type Roughing type øDb

- Page 71 and 72: TPD / EPD type Diameter ø12 ~ 40 m

- Page 73 and 74: 1.4 1.4 TPW13 Diameter ø50 ~ 125 m

- Page 75 and 76:

9 TAC Mills EPH Shoulder Milling Ca

- Page 77 and 78:

EPH Standard cutting conditions Sh

- Page 79 and 80:

EVH Diameter ø10 ~ 16 mm 90° ~ 4.

- Page 81 and 82:

All PCD-tipped TAC Mills for high f

- Page 83 and 84:

TAC Mills for large depth of cut TP

- Page 85 and 86:

TAC Mills TSE3000R(IA)E Face Millin

- Page 87 and 88:

TAC Mills TSE4000RIAE Face Milling

- Page 89 and 90:

Top-Feed Mills, AD TPS/EPS17 Should

- Page 91 and 92:

Top-Feed Mills, AD TPS/EPS17 Machin

- Page 93 and 94:

15°17° 1 mm ø16 ~ 80 mm Air Hole

- Page 95 and 96:

Standard cutting conditions Work ma

- Page 97 and 98:

Standard cutting conditions Work ma

- Page 99 and 100:

TXQ12R ø50~125 mm 2 mm Steel Stain

- Page 101 and 102:

EXH Diameter ø10 ~ 16 mm 20° 0.6,

- Page 103 and 104:

T/EXP Diameter ø20 ~ 125 mm 10°,

- Page 105 and 106:

T/EXP Inserts 05 type General inser

- Page 107 and 108:

T/EXP Diameter ø20 ~ 160 mm 10°,

- Page 109 and 110:

TRC / ERC type Inserts For general

- Page 111 and 112:

TAC Flash radius mills TRD12 • 16

- Page 113 and 114:

TAC radius mills T/ERF6000 Diameter

- Page 115 and 116:

TAC Flash endmills with center cutt

- Page 117 and 118:

TAC Flash Endmills ESD10 Shoulder M

- Page 119 and 120:

TAC Flash ball endmills EBP R Radiu

- Page 121 and 122:

TAC ball Endmills TBN1000 Pocketing

- Page 123 and 124:

TAC Flash Mills for plunging TZP12

- Page 125 and 126:

TAC Flash Mills for plunging TZF11

- Page 127 and 128:

“T-Bar” Modular System TMS Diam

- Page 129 and 130:

TAC Flasah chamfering mills ECC31 G

- Page 131 and 132:

TAC Mills for super finishing SFP40

- Page 133 and 134:

All PCBN-tipped TAC Mills for high

- Page 135 and 136:

ASN / TSN ø100 ~ 250 mm Steel Stai

- Page 137 and 138:

ASN / TSN Replacement parts Work ma

- Page 139 and 140:

Mounting Details for TAC Mills Cutt

- Page 141 and 142:

TAC Milling Inserts Inserts ADMT08P

- Page 143 and 144:

TAC Milling Inserts AST11T3PDR-MJ/M

- Page 145 and 146:

TAC Milling Inserts LMEUZNEN-MJ Sha

- Page 147 and 148:

TAC Milling Inserts ONUAN-ML/MJ/W S

- Page 149 and 150:

TAC Milling Inserts SCMT08-23 Shape

- Page 151 and 152:

TAC Milling Inserts SEN1203AG, SEKR

- Page 153 and 154:

TAC Milling Inserts SPHA431FNW, SPH

- Page 155 and 156:

TAC Milling Inserts SW13T3AFR- Shap

- Page 157 and 158:

TAC Milling Inserts TEN43Z, TECN43Z

- Page 159 and 160:

TAC Milling Inserts XCET310404ER St

- Page 161 and 162:

TAC Milling Inserts XVGTEC-MJ, XVG

- Page 163 and 164:

TAC Milling Inserts ZDAT/FN Shape C