PDFï¼7.7MB

PDFï¼7.7MB

PDFï¼7.7MB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

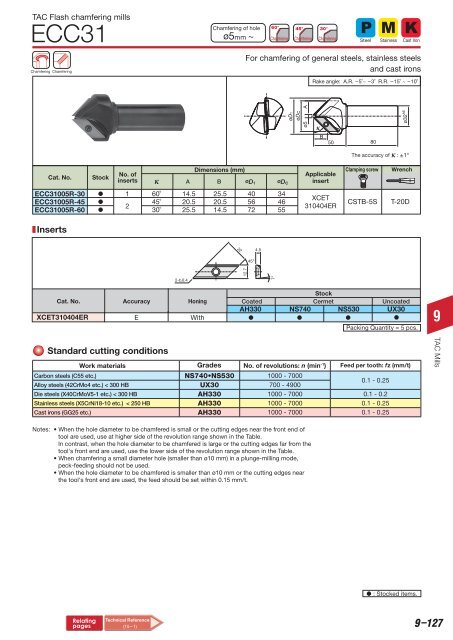

TAC Flash chamfering mills<br />

ECC31<br />

Chamfering Chamfering<br />

Chamfering of hole<br />

ø5mm ~<br />

60° 45° 30°<br />

Chamfering Chamfering Chamfering<br />

Steel<br />

Stainless<br />

Cast Iron<br />

For chamfering of general steels, stainless steels<br />

and cast irons<br />

Rake angle: A.R. —5˚~ —3˚ R.R. —15˚ ~ —10˚<br />

øD1<br />

øDc<br />

ø5<br />

A<br />

κ<br />

B<br />

50<br />

80<br />

ø32 h6<br />

The accuracy of κ : ±1°<br />

Cat. No.<br />

Stock<br />

No. of<br />

inserts<br />

Dimensions (mm)<br />

κ A B øD 1 øDc<br />

Applicable<br />

insert<br />

Clamping screw<br />

Wrench<br />

ECC31005R-30<br />

ECC31005R-45<br />

ECC31005R-60<br />

<br />

<br />

<br />

1<br />

2<br />

60˚ 14.5 25.5 40 34<br />

45˚ 20.5 20.5 56 46<br />

30˚ 25.5 14.5 72 55<br />

XCET<br />

310404ER<br />

CSTB-5S<br />

T-20D<br />

Inserts<br />

22<br />

4.5<br />

45°<br />

2-r ε0.4<br />

12.7<br />

7°<br />

Stock<br />

Cat. No. Accuracy Honing<br />

Coated Cermet Uncoated<br />

AH330 NS740 NS530 UX30<br />

XCET310404ER E With<br />

<br />

<br />

<br />

<br />

Packing Quantity = 5 pcs.<br />

9<br />

Standard cutting conditions<br />

Work materials<br />

Carbon steels (C55 etc.)<br />

Alloy steels (42CrMo4 etc.) < 300 HB<br />

Die steels (X40CrMoV5-1 etc.) < 300 HB<br />

Stainless steels (X5CrNi18-10 etc.) < 250 HB<br />

Cast irons (GG25 etc.)<br />

Grades<br />

No. of revolutions: n (min -1 )<br />

Feed per tooth: fz (mm/t)<br />

NS740•NS530 1000 - 7000<br />

UX30 700 - 4900<br />

0.1 - 0.25<br />

AH330 1000 - 7000 0.1 - 0.2<br />

AH330 1000 - 7000 0.1 - 0.25<br />

AH330 1000 - 7000 0.1 - 0.25<br />

TAC Mills<br />

Notes: • When the hole diameter to be chamfered is small or the cutting edges near the front end of<br />

tool are used, use at higher side of the revolution range shown in the Table.<br />

In contrast, when the hole diameter to be chamfered is large or the cutting edges far from the<br />

tool's front end are used, use the lower side of the revolution range shown in the Table.<br />

• When chamfering a small diameter hole (smaller than ø10 mm) in a plunge-milling mode,<br />

peck-feeding should not be used.<br />

• When the hole diameter to be chamfered is smaller than ø10 mm or the cutting edges near<br />

the tool's front end are used, the feed should be set within 0.15 mm/t.<br />

: Stocked items.<br />

<br />

<br />

Technical Reference<br />

(15-1)<br />

9–127