PDFï¼7.7MB

PDFï¼7.7MB

PDFï¼7.7MB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TPS / EPS11<br />

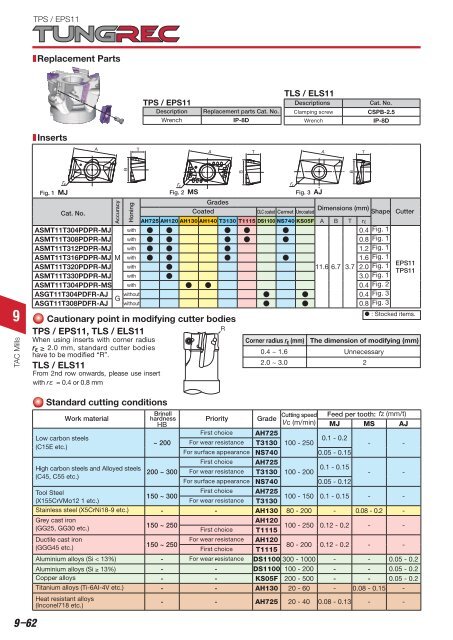

Replacement Parts<br />

TPS / EPS11<br />

Description<br />

Wrench<br />

Replacement parts Cat. No.<br />

IP-8D<br />

TLS / ELS11<br />

Descriptions<br />

Clamping screw<br />

Wrench<br />

Cat. No.<br />

CSPB-2.5<br />

IP-8D<br />

Inserts<br />

A<br />

T<br />

A<br />

T<br />

A<br />

T<br />

B<br />

B<br />

B<br />

9<br />

TAC Mills<br />

ε<br />

Fig. 1 MJ<br />

ε<br />

Grades<br />

Cat. No.<br />

Coated<br />

DLC coated Cermet Uncoated Dimensions (mm) Shape Cutter<br />

AH725 AH120 AH130 AH140 T3130 T1115 DS1100 NS740 KS05F A B T rε<br />

ASMT11T304PDPR-MJ with <br />

0.4 Fig. 1<br />

ASMT11T308PDPR-MJ with 0.8 Fig. 1<br />

ASMT11T312PDPR-MJ with 1.2 Fig. 1<br />

ASMT11T316PDPR-MJ M with 1.6 Fig. 1<br />

EPS11<br />

ASMT11T320PDPR-MJ with 11.6 6.7 3.7 2.0 Fig. 1<br />

TPS11<br />

ASMT11T330PDPR-MJ with 3.0 Fig. 1<br />

ASMT11T304PDPR-MS with<br />

0.4 Fig. 2<br />

ASGT11T304PDFR-AJ without<br />

G<br />

0.4 Fig. 3<br />

ASGT11T308PDFR-AJ without<br />

0.8 Fig. 3<br />

Accuracy<br />

Honing<br />

Fig. 2 MS<br />

Cautionary point in modifying cutter bodies<br />

R<br />

TPS / EPS11, TLS / ELS11<br />

When using inserts with corner radius<br />

r ε 2.0 mm, standard cutter bodies<br />

have to be modified “R”.<br />

TLS / ELS11<br />

From 2nd row onwards, please use insert<br />

with r = 0.4 or 0.8 mm<br />

ε<br />

Fig. 3 AJ<br />

: Stocked items.<br />

Corner radius r ε (mm) The dimension of modifying (mm)<br />

0.4 ~ 1.6<br />

Unnecessary<br />

2.0 ~ 3.0 2<br />

9–62<br />

Standard cutting conditions<br />

Work material<br />

Low carbon steels<br />

(C15E etc.)<br />

High carbon steels and Alloyed steels<br />

(C45, C55 etc.)<br />

Tool Steel<br />

(X155CrVMo12 1 etc.)<br />

Stainless steel (X5CrNi18-9 etc.)<br />

Grey cast iron<br />

(GG25, GG30 etc.)<br />

Ductile cast iron<br />

(GGG45 etc.)<br />

Aluminium alloys (Si < 13%)<br />

Aluminium alloys (Si 13%)<br />

Copper alloys<br />

Titanium alloys (Ti-6AI-4V etc.)<br />

Heatresistant alloys<br />

(Inconel718 etc.)<br />

Brinell<br />

Cutting speed Feed per tooth: fz (mm/t)<br />

hardness Priority Grade<br />

HB<br />

Vc (m/min) MJ MS AJ<br />

First choice AH725<br />

0.1 - 0.2<br />

~ 200 For wear resistance T3130 100 - 250<br />

- -<br />

For surface appearance NS740 0.05 - 0.15<br />

First choice AH725<br />

200 ~ 300 For wear resistance T3130 100 - 200 0.1 - 0.15 - -<br />

For surface appearance NS740 0.05 - 0.12<br />

150 ~ 300<br />

First choice AH725<br />

For wear resistance T3130 100 - 150 0.1 - 0.15 - -<br />

- - AH130 80 - 200 - 0.08 - 0.2 -<br />

AH120<br />

150 ~ 250<br />

First choice T1115 100 - 250 0.12 - 0.2 - -<br />

150 ~ 250<br />

For wear resistance AH120<br />

First choice T1115 80 - 200 0.12 - 0.2 - -<br />

- For wear -resistance<br />

DS1100 300 - 1000 - - 0.05 - 0.2<br />

- - DS1100 100 - 200 - - 0.05 - 0.2<br />

- - KS05F 200 - 500 - - 0.05 - 0.2<br />

- - AH130 20 - 60 - 0.08 - 0.15 -<br />

- - AH725 20 - 40 0.08 - 0.13 - -